Kiln flue gas collection treatment device and treatment process of kiln flue gas

A treatment device and flue gas technology, applied in gas treatment, waste heat treatment, furnaces, etc., can solve problems affecting the environment, and achieve the effects of reducing environmental pollution, reducing carbon dioxide, nitrogen and dust emissions, and reducing the temperature of the kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

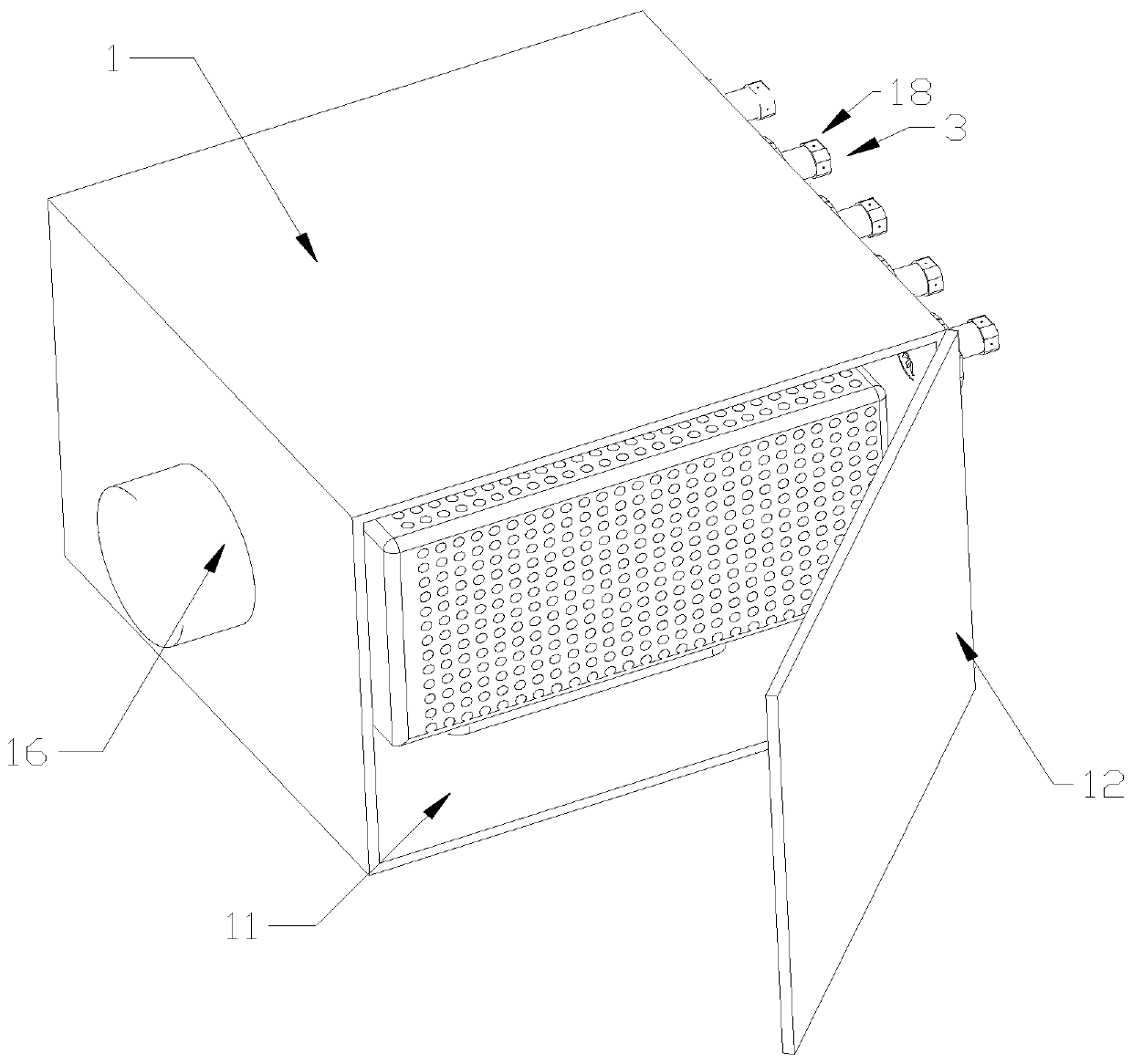

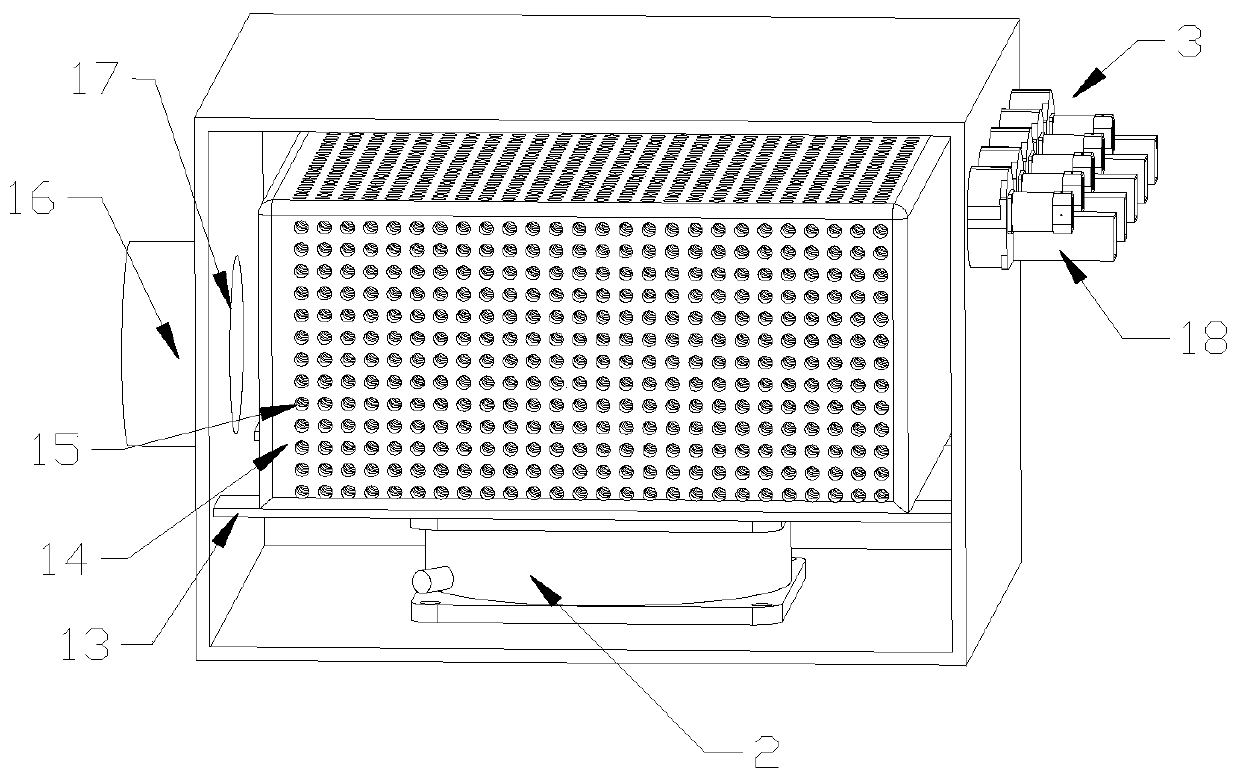

[0036] A kiln flue gas treatment process, comprising the following steps:

[0037] Step 1: Set up a 1000x1000 supervisor from the exit of the supervisor of the moisture discharge chamber of the drying kiln to the No. 28 and No. 29 parking spaces of the roasting kiln, and connect the supervisor to the intake pipe 16 at the same time.

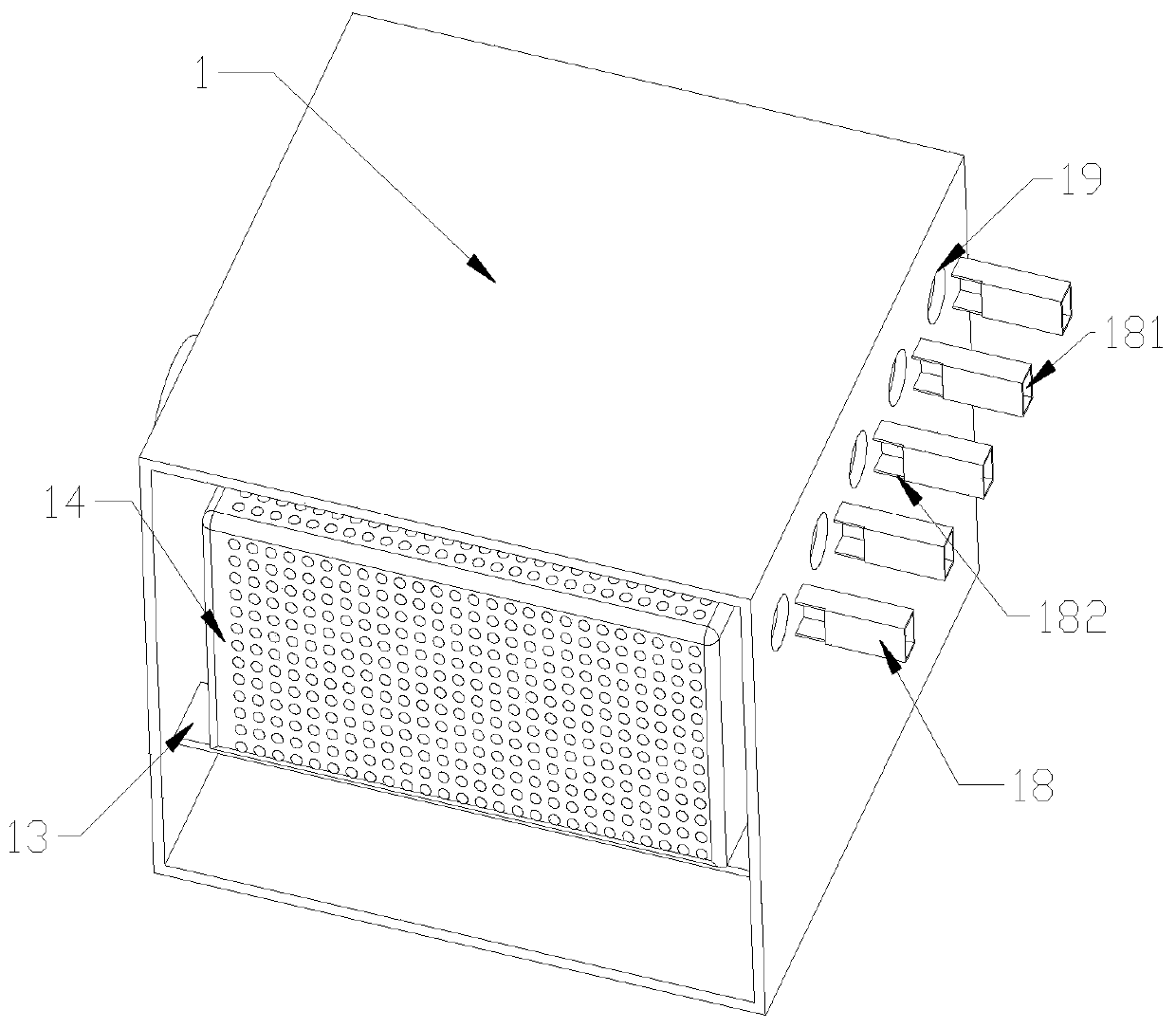

[0038] Step 2: Set five pairs of 300x500 air ducts on both sides of the roasting kiln to connect with the air outlet pipe 18.

[0039] Step 3: Install a 45KW centrifugal exhaust fan in the intake pipe 16 to extract smoke and moisture into the treatment box 1 .

[0040] Step 4: Start the circulation fan 2 to fully move the flue gas and moisture drawn into the treatment box 1, and the activated carbon box 14 adsorbs carbon dioxide, nitrogen compounds and dust in the flue gas and moisture.

[0041] Step 5: Start the centrifugal fan 3, draw the treated flue gas and moisture in the treatment box 1 into the outlet pipe 18, and then enter the kiln tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com