Active energy ray curable composition and hard coat film

An active energy ray, curable composition technology, applied in the direction of coating, etc., can solve the problems of reduced yield, adhesion (decreased light resistance adhesion, insufficient scratch resistance on the surface of the cured coating film, etc.) The effect of high scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

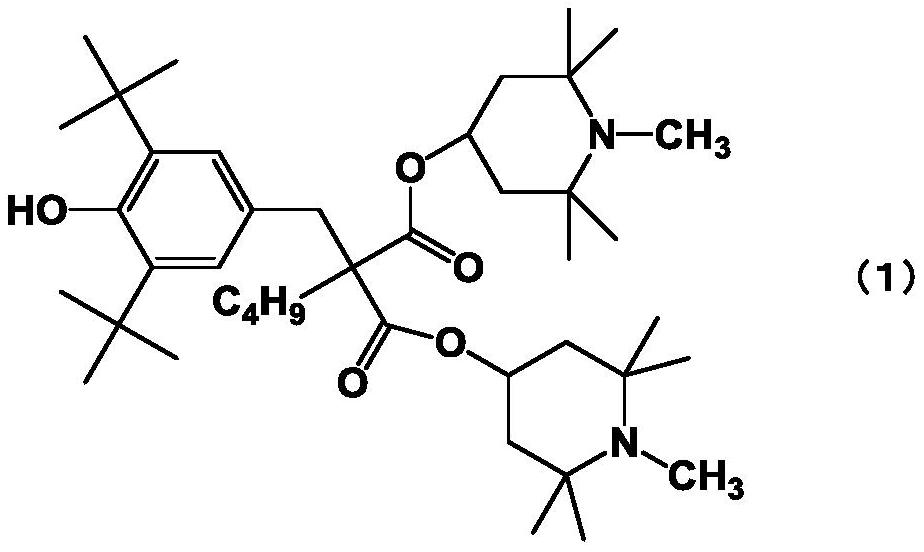

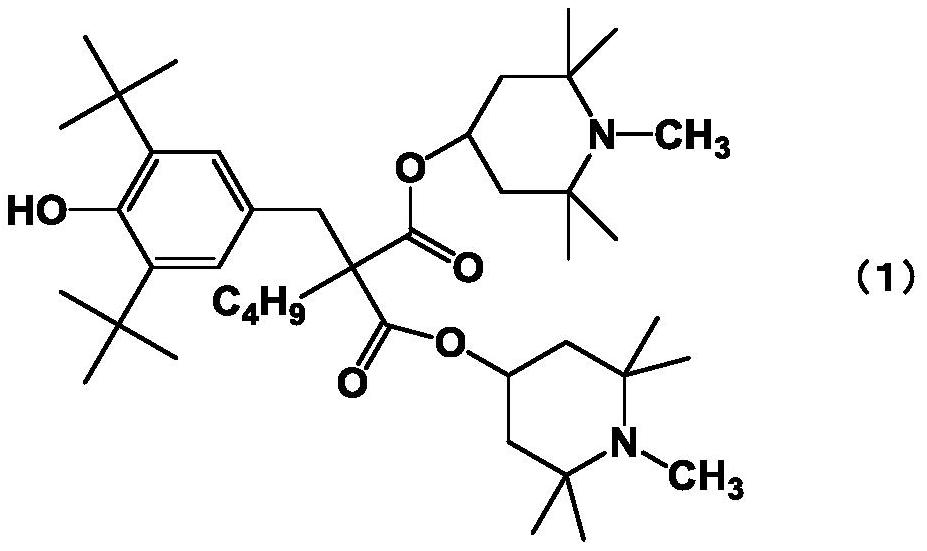

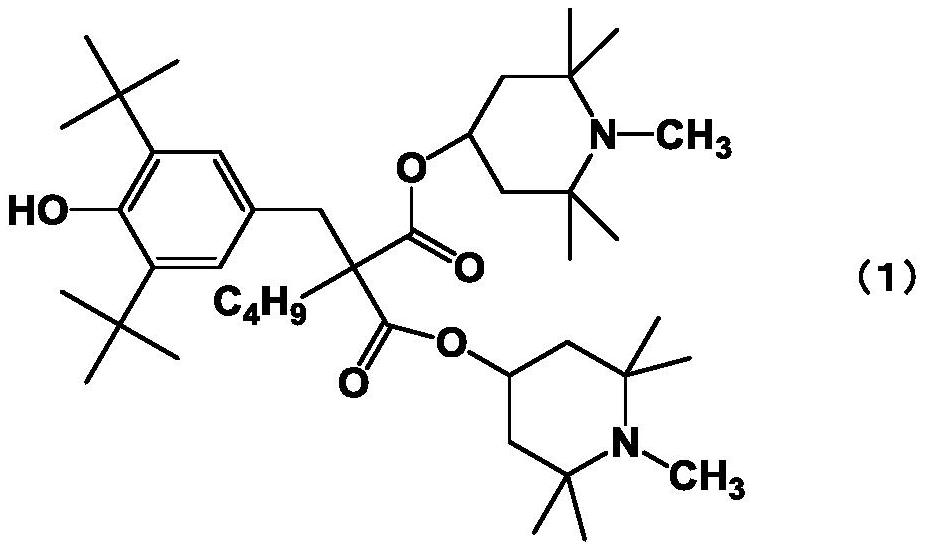

Image

Examples

Embodiment 1

[0069] 100 Parts by mass, silica fine particles ("MEK-ST40" manufactured by Nissan Chemical Industries, Ltd., average particle diameter 10-20nm, 40 mass% methyl ethyl ketone dispersion of organic silica sol (colloidal silica)) 26 mass parts ( Calculated as silica particles), hindered amine light stabilizer with methacryloyl group ("ADK STAB (registered trademark) LA-87" manufactured by ADEKA Co., Ltd.; 2,2,6,6-tetramethyl-4 -piperidinyl methacrylate) 0.5 parts by mass, 1-hydroxycyclohexyl phenyl ketone ("IRGACURE (registered trademark) 184" manufactured by BASF Japan Co., Ltd.) 6 parts by mass, methyltrimethoxysilane (Shin-Etsu Chemical Co., Ltd. Kogyo Co., Ltd. product "KBM-13") 20 mass parts was uniformly stirred, and diluted with methyl ethyl ketone, and the active energy ray curable composition (1) whose nonvolatile matter was 40 mass % was prepared.

Embodiment 2

[0071] Except having changed the compounding quantity of ADK STAB LA-87 into 0.1 mass part from 0.5 mass part, it carried out similarly to Example 1, and prepared the active energy ray curable composition (2).

Embodiment 3

[0073] Except having changed the compounding quantity of ADK STAB LA-87 into 1 mass part from 0.5 mass part, it carried out similarly to Example 1, and prepared the active energy ray curable composition (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com