Method for processing lead screw or roller of small and miniature planetary roller screw pair

A technology of planetary rollers and processing methods, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of low failure rate, long life, small size, etc., to increase the thread strength and overcome the sharp angle effect. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

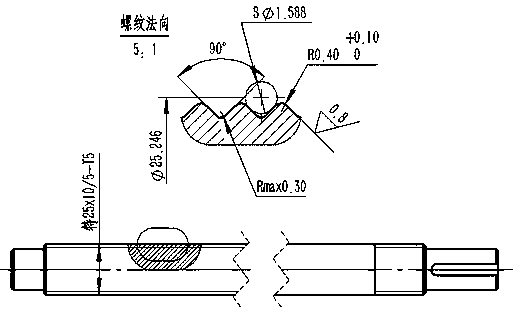

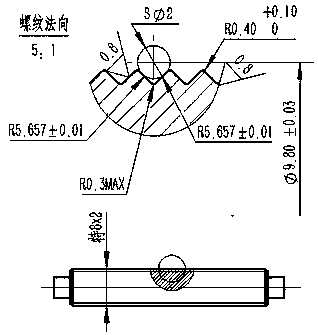

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] figure 1 It is the structure diagram of the planetary screw after processing and forming, figure 2 It is the structural diagram of the planetary roller after processing and forming. The diameter of the screw or roller involved in the present invention is less than 10mm, and the aspect ratio coefficient is greater than 1:50. If this small miniature planetary roller screw adopts the grinding process production, it is difficult to achieve the requirement that the aspect ratio exceeds 1:50. Even so, the product processing is difficult, the manufacturing cost is high, and the accuracy is difficult to guarantee. After the invention is realized, the requirement of large length-to-diameter ratio of the product can be easily realized, the manufacturing cost of the product can be greatly reduced, and the application range can be expanded. Moreover, it is energy-saving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com