Test platform for driven grinding mode of steel rail

A technology for testing platforms and rails, which is applied to measuring devices, instruments, and mechanical devices, etc., and can solve the problems that passive grinding wheels cannot be independently localized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

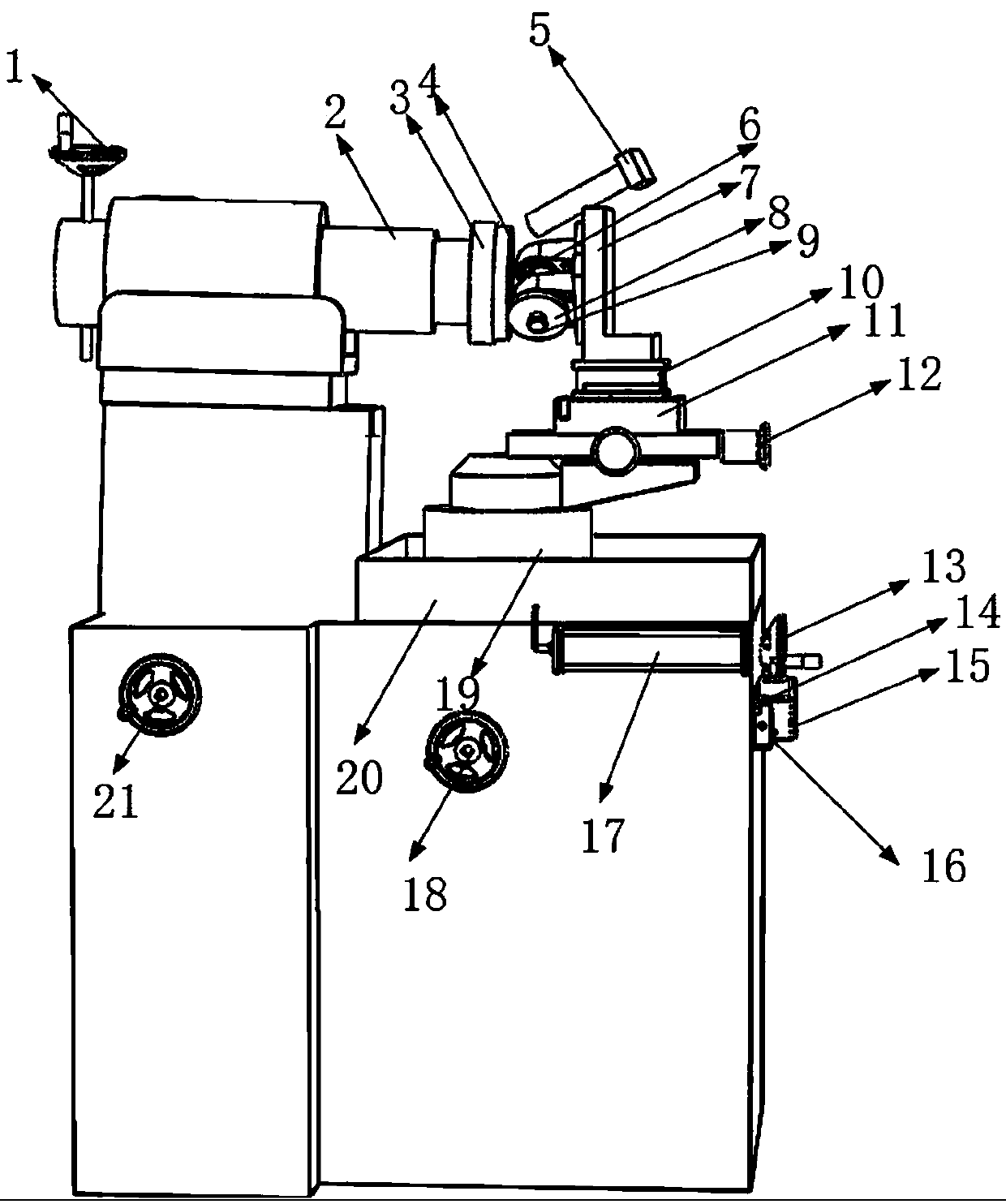

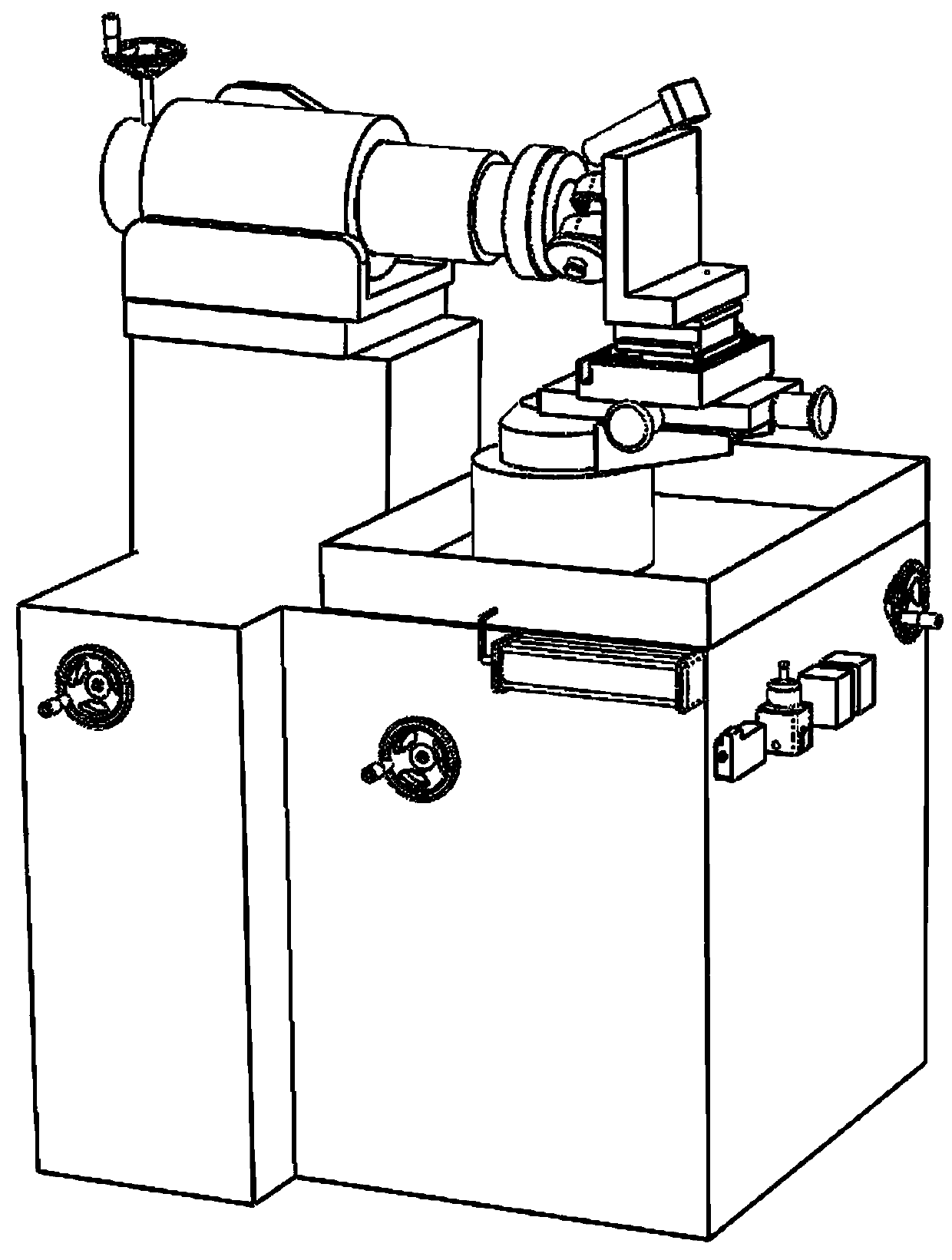

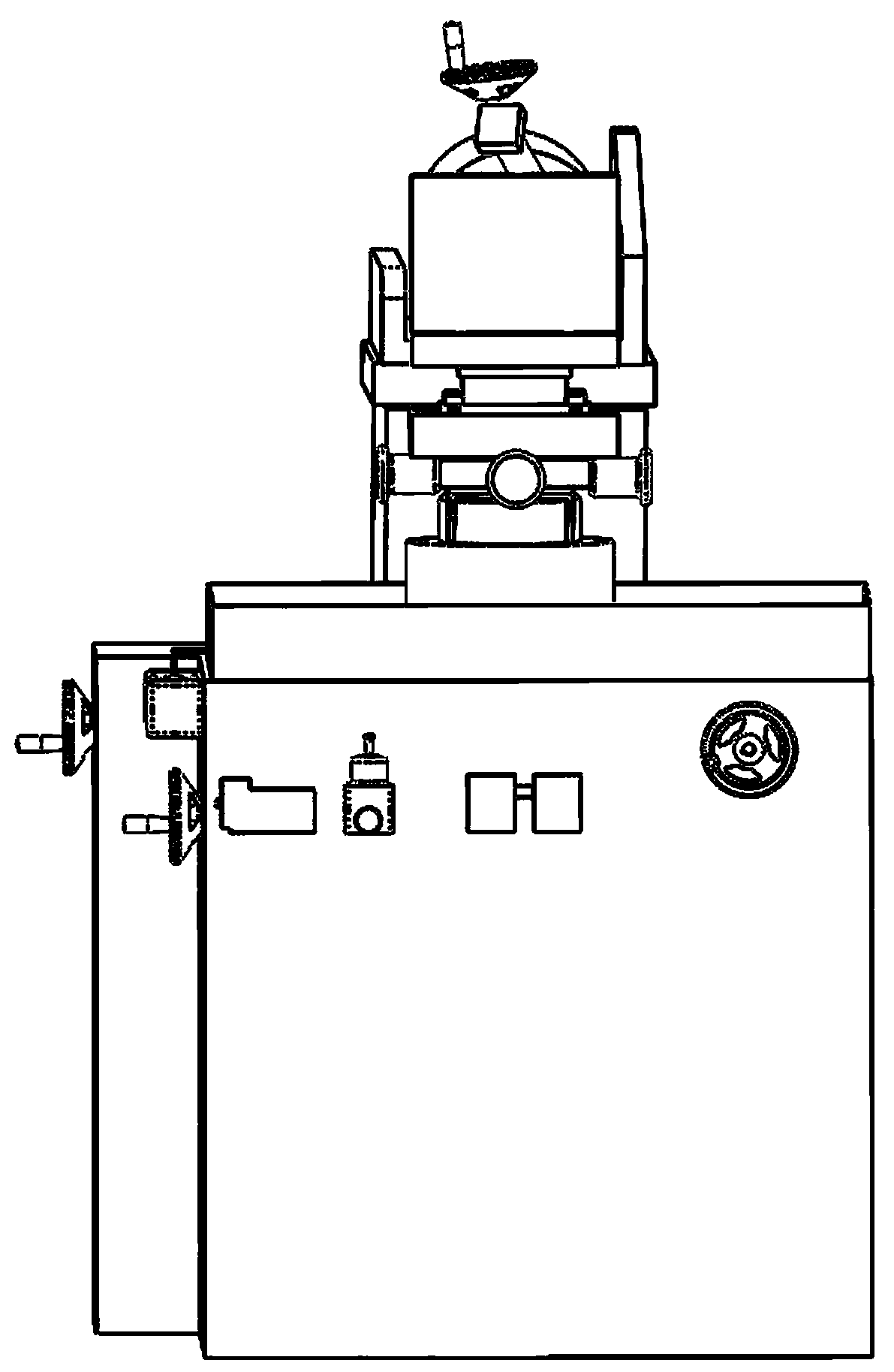

[0035] Such as figure 1 As shown, the test platform of the rail passive grinding mode of the present invention comprises a motor 1 installed on the machine tool control cabinet through height adjustment and front and rear displacement mechanisms, and a rail disc sample 4 installed on the front end of the motor spindle; The passive grinding wheel 8 installed on the machine tool workbench in such a way that the sample is relatively arranged, the passive grinding wheel 8 is installed on one end of the bearing shaft 9, and the bearing shaft 9 is fixed on one side of the L-shaped supporting steel plate 7 through the bearing with seat 6; The L-shaped support steel plate 7 installs the base fixed platform 11 through the three-dimensional mechanical sensor 10, and the base fixed platform 11 is installed on the high and low lifting platform 19 through the horizontal ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com