Metal dot color optical filter, manufacturing method thereof and liquid crystal display device

A technology for color filters and manufacturing methods, which is applied in the direction of filters, optics, optical components, etc., can solve the problems of heavy toxicity and high cost of quantum dot color filters, and achieve ultra-small size, abundant reserves, and soluble good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

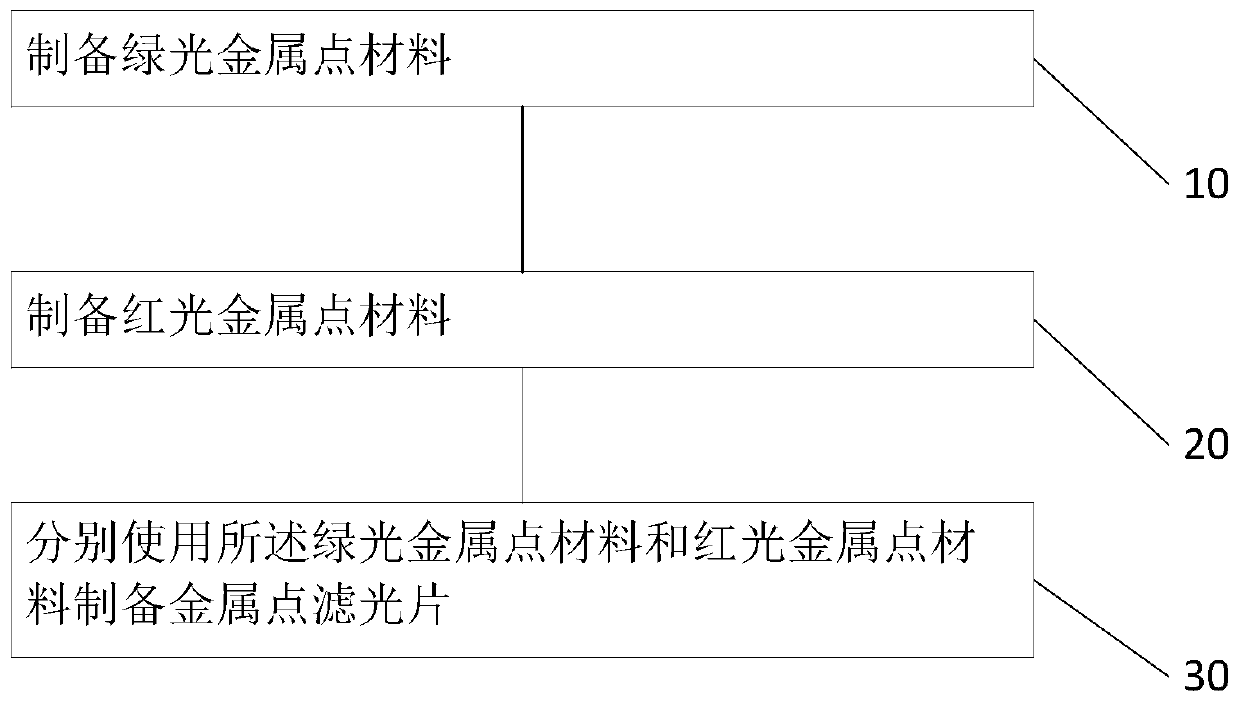

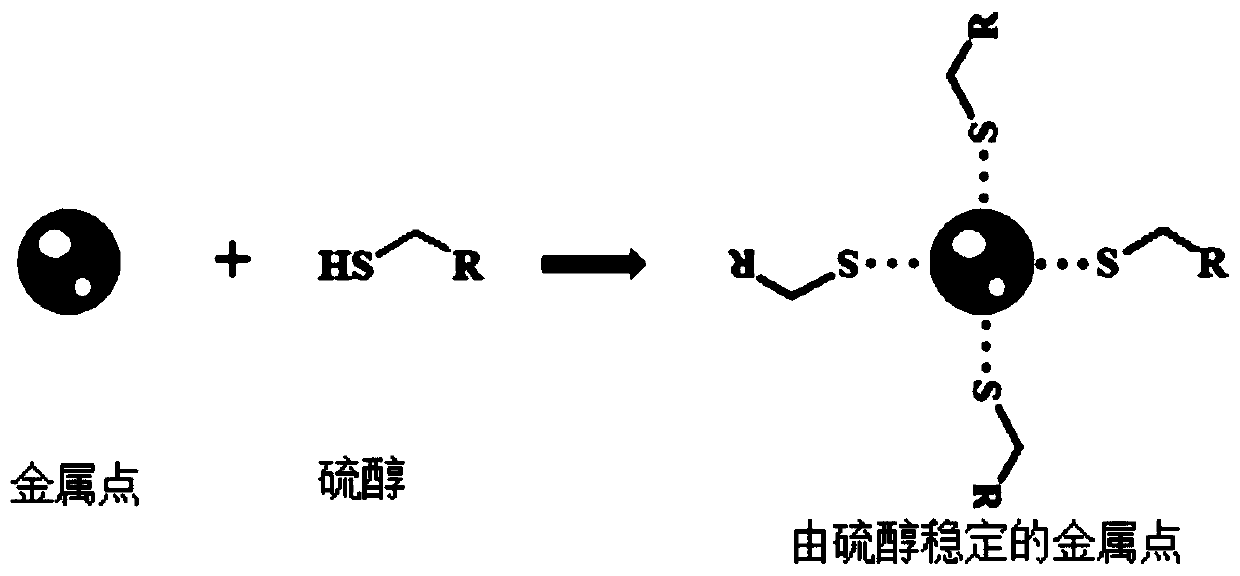

[0047] The present invention mainly uses the metal dot material instead of the quantum dot material to prepare a color film photoresist, that is, a metal dot color filter (metal dot color filter, MDCF). Correspondingly, the present invention provides a metal dot color filter, which comprises a green light metal dot material with a fluorescence peak close to 530 nanometers or a red light metal dot material with a fluorescence peak close to 635 nanometers, the green light metal dot material and The particle size of the red light metal dot material is less than 2 nanometers. Wherein, the green light metal dot material and the red light metal dot material may be metal dot materials prepared according to the manufacturing method of the metal dot color filter of the present invention.

[0048] Recently, metal dot materials have been applied in the field of electroluminescent or photoluminescent LEDs. Their properties are similar to those of quantum dot materials. They have a quantum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com