Preparation and application of a core-shell structured ti-zr-si composite photocatalyst with strong absorption of incident light

A technology of ti-zr-si and core-shell structure is applied in the preparation and application of core-shell structure powder and core-shell structure Ti-Zr-Si composite photocatalyst, which can solve the problem of not many reports on incident light, etc. High light absorption rate, simple method, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A core-shell structure Ti-Zr-Si composite photocatalyst preparation process with strong absorption of incident light, the specific process is as follows:

[0028] (1) Step 1: under the condition of continuous magnetic stirring, add alkaline reagent ammonia water to 20 mL of deionized water, adjust pH=7~10, dissolve zirconium oxychloride and metal ion complexing agent in the above deionized water, prepare A uniform and transparent solution with a zirconium ion concentration of 0.05moL / L was obtained, that is, a zirconium precursor solution. Wherein, the mass ratio of zirconium oxychloride and metal ion complexing agent is 0.5:2. The ethyl orthosilicate solution was prepared by dissolving ethyl orthosilicate in absolute ethanol. Dissolve titanium sulfate in deionized water to prepare a titanium solution. The addition amounts of ethyl orthosilicate and titanium sulfate were determined according to n(Ti):n(Zr):n(Si)=6:1:4. Under the condition of continuous magnetic stirr...

Embodiment 2

[0031]The preparation process of a core-shell structure Ti-Zr-Si composite photocatalyst with strong absorption of incident light is the same as in Example 1, except that the calcination time after impregnation is different.

[0032] In this example, the calcination temperature after impregnation was 400°C.

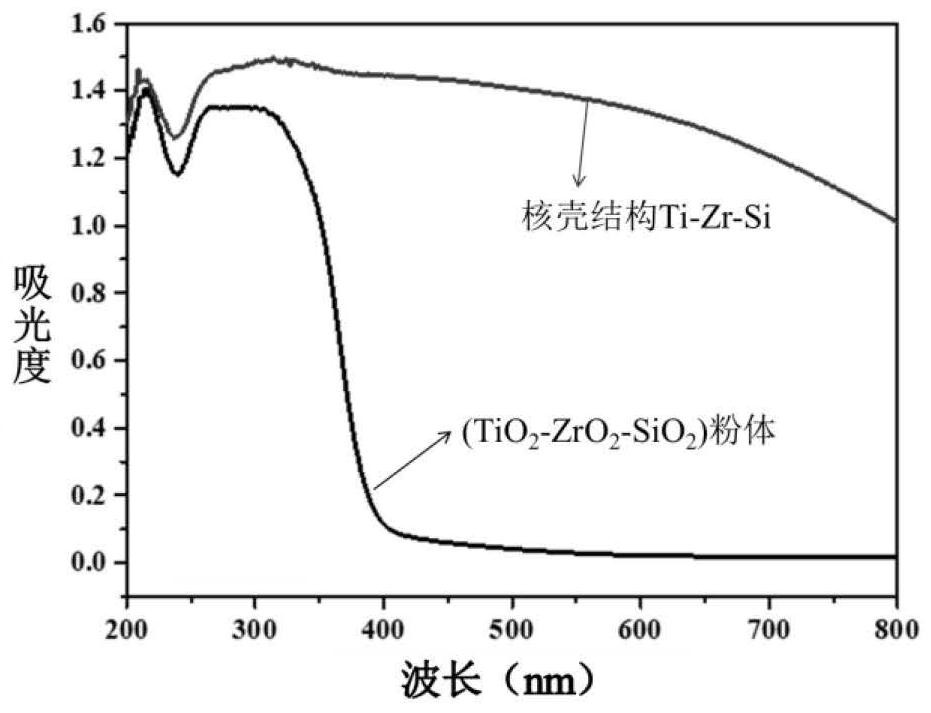

[0033] figure 1 is the white (TiO) prepared in Example 2 2 -ZrO 2 -SiO 2 ) (a) and UV-vis absorption spectra of the core-shell structured Ti-Zr-Si composite photocatalyst (b). It can be seen from the figure that the white (TiO 2 -ZrO 2 -SiO 2 ) The composite photocatalyst hardly absorbs incident light with a wavelength greater than 400 nm. The core-shell structure Ti-Zr-Si composite photocatalyst has a high absorption intensity in the entire visible light range, indicating that its response to visible light has a strong absorption effect.

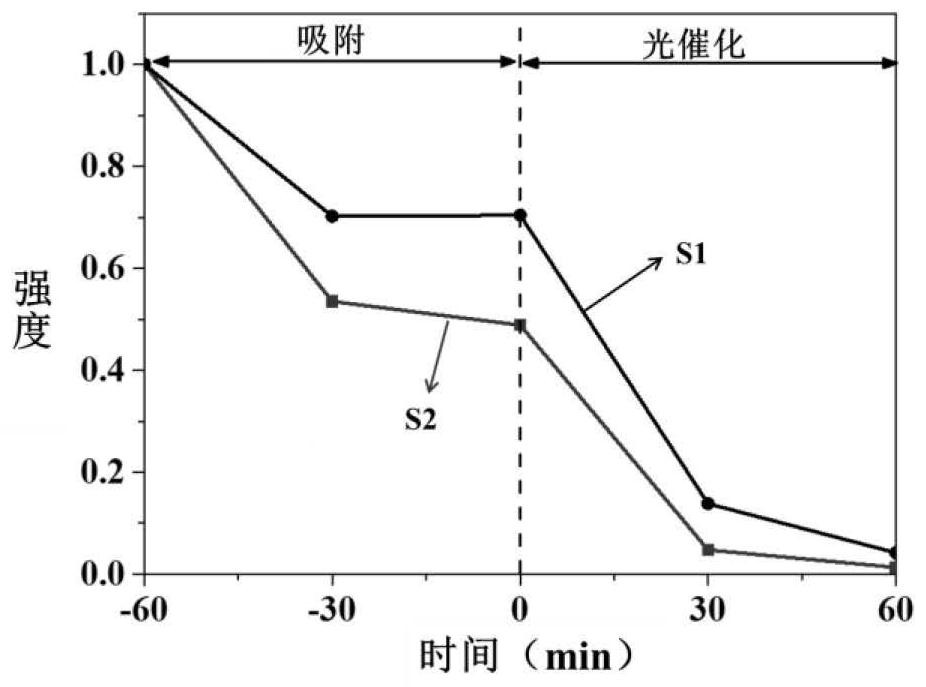

[0034] figure 2 is white (TiO 2 -ZrO 2 -SiO 2 ) (S1) and the photocatalytic degradation of Rhodamine B by the core-shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com