Modified silicon negative electrode material for lithium ion battery and preparation method and application thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as loss of effective mass, loss of electrical contact of collectors, lithium consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 200g of nano-sized silicon particles (particle size: 80-150nm) in a mixed solution of 120mL of concentrated sulfuric acid and hydrogen peroxide (volume ratio: 1:1) and soak for 10min, then centrifuge and wash. Take 100g surface hydroxylated nano-sized silicon particles and add to 160mL ultrapure water and mix well, add 10mL dissolved 0.16g methyl triethoxy silicon (surface hydroxylated nano-sized silicon particles and methyl triethoxy silicon The mass ratio is 1000:1.6) ethanol solution, after stirring for 8 hours, it is centrifuged and dried to obtain a modified silicon negative electrode material, which is denoted as Si-CH 3 .

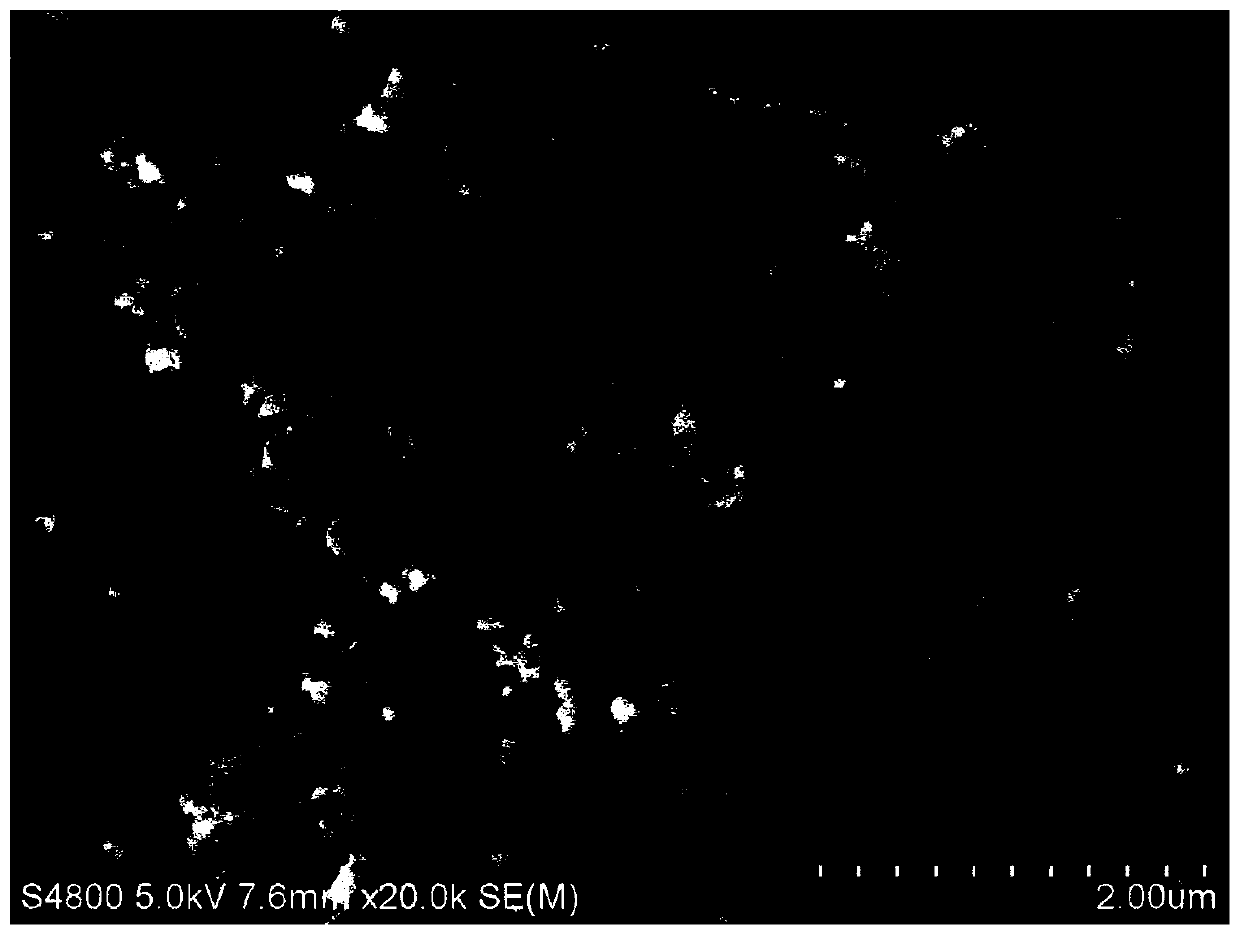

[0042] figure 1 The SEM picture of the modified silicon negative electrode material prepared for this example shows that the particle size of the modified silicon negative electrode particles is between 80 and 150 nm, and the particles are well dispersed without obvious agglomeration.

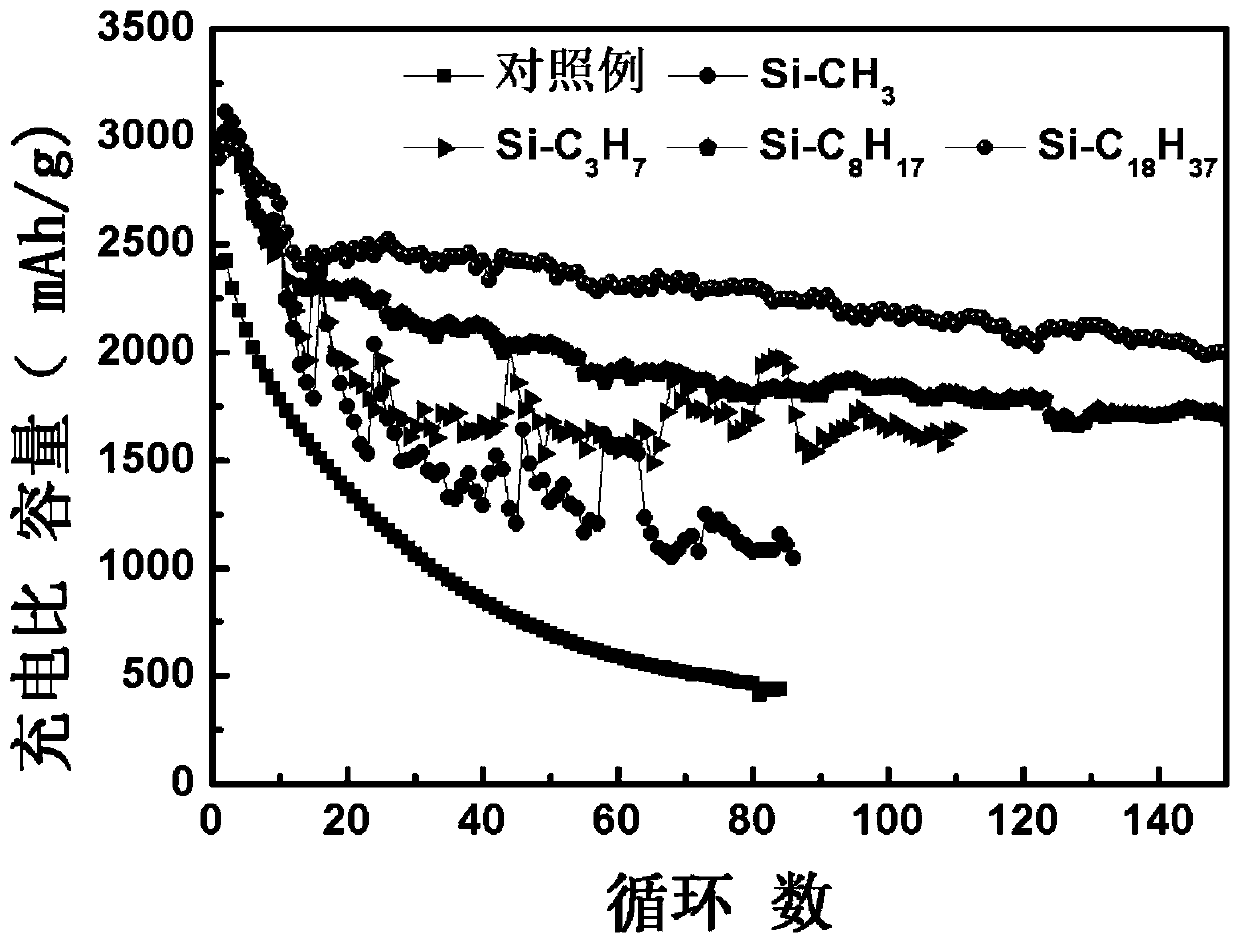

[0043] The modified silicon negative electrode mat...

Embodiment 2

[0049] Take 200g of nano-sized silicon particles and soak them in a mixed solution of 120mL of concentrated sulfuric acid and hydrogen peroxide (volume ratio: 1:1) for 10min, then centrifuge and wash them. Take 100g surface hydroxylated nano-sized silicon particles and add to 160mL ultrapure water and mix well, add 10mL dissolved 0.19g methyl triethoxy silicon (surface hydroxylated nano-sized silicon particles and methyl triethoxy silicon The mass ratio is 1000:1.9) ethanol solution, after stirring for 8 hours, it is centrifugally cleaned and dried to obtain a modified silicon negative electrode material, which is denoted as Si-C 3 h 7 .

[0050] The modified silicon negative electrode material prepared in this example was equipped as a half cell to test the cycle performance, and the preparation and test conditions were the same as those in Example 1. Battery performance test results: the first cycle discharge capacity is 2967mAh / g, the first coulombic efficiency is 91.7%, ...

Embodiment 3

[0052] Take 200g of nano-sized silicon particles and soak them in a mixed solution of 120mL of concentrated sulfuric acid and hydrogen peroxide (volume ratio: 1:1) for 10min, then centrifuge and wash them. Take 100g surface hydroxylated nano-sized silicon particles and add to 160mL ultrapure water and mix well, add and dissolve 10mL 0.26g methyl triethoxy silicon (surface hydroxylated nano-sized silicon particles and methyl triethoxy silicon The mass ratio is 1000:2.6) ethanol solution, after stirring for 8 hours, it is centrifuged and dried to obtain a modified silicon negative electrode material, which is denoted as Si-C 8 h 17 .

[0053] The modified silicon negative electrode material prepared in this example was equipped as a half cell to test the cycle performance, and the preparation and test conditions were the same as those in Example 1. Battery performance test results: the first cycle discharge capacity is 2995mAh / g, the first coulombic efficiency is 90.3%, the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com