Moist heat sterilization equipment for Ganoderma lucidum spore powder

A technology of ganoderma lucidum spore powder and moist heat sterilization, which is applied in the direction of heating, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of poor sterilization quality and low sterilization efficiency, and achieve improved quality, improved sterilization efficiency and Quality, dryness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

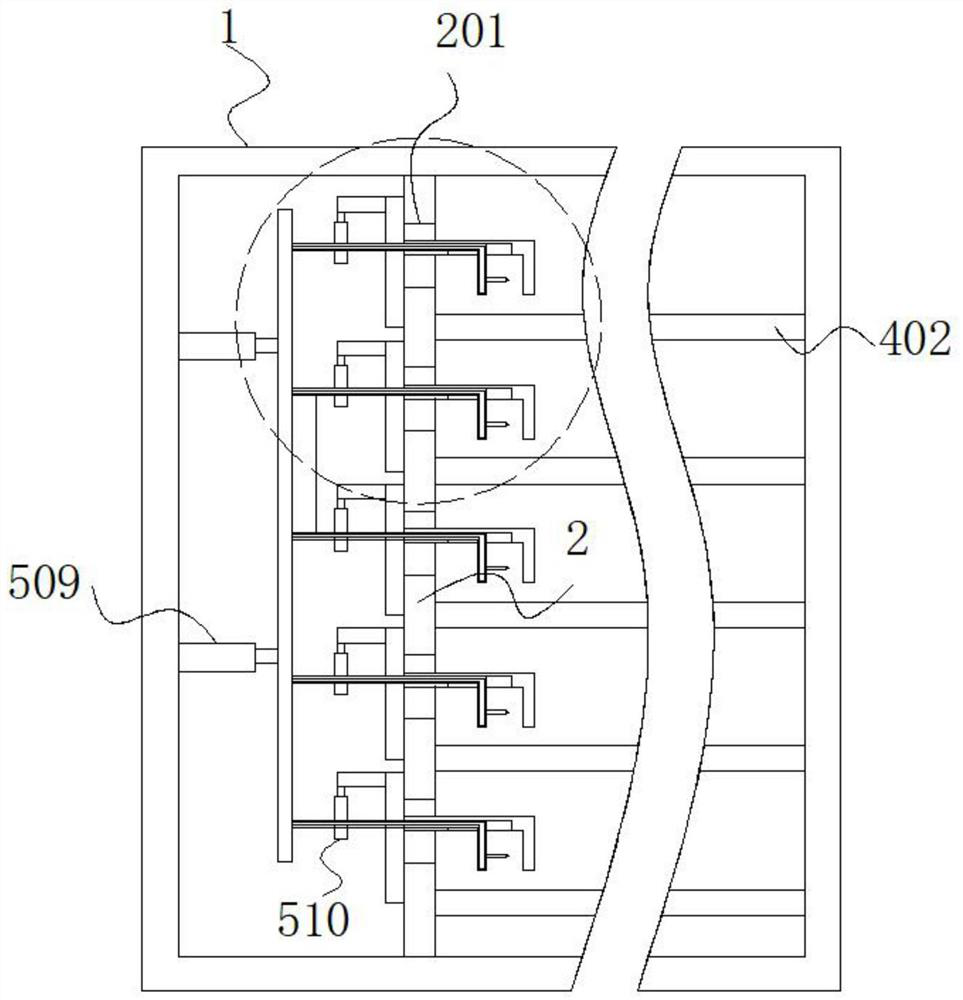

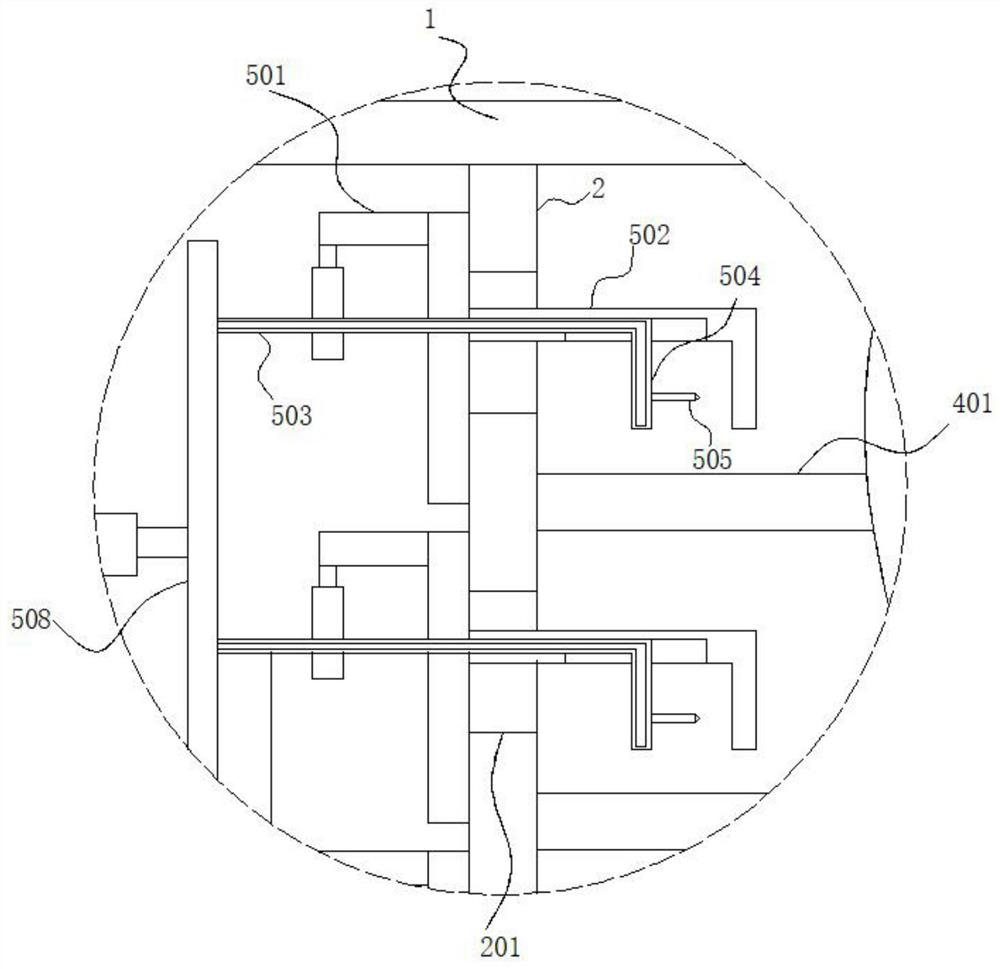

[0032] The side of the active plate 508 away from the docking sleeve 503 is equipped with a second push mechanism 509 affixed to the sterilization box 1, and the bottom of the side of the push plate 501 away from the partition 2 is equipped with a second push mechanism 509 affixed to the sterilizer 1. A pushing mechanism 510, the first pushing mechanism 510, the second pushing mechanism 509, the fourth pushing mechanism and the third pushing mechanism all adopt linear motors;

Embodiment 2

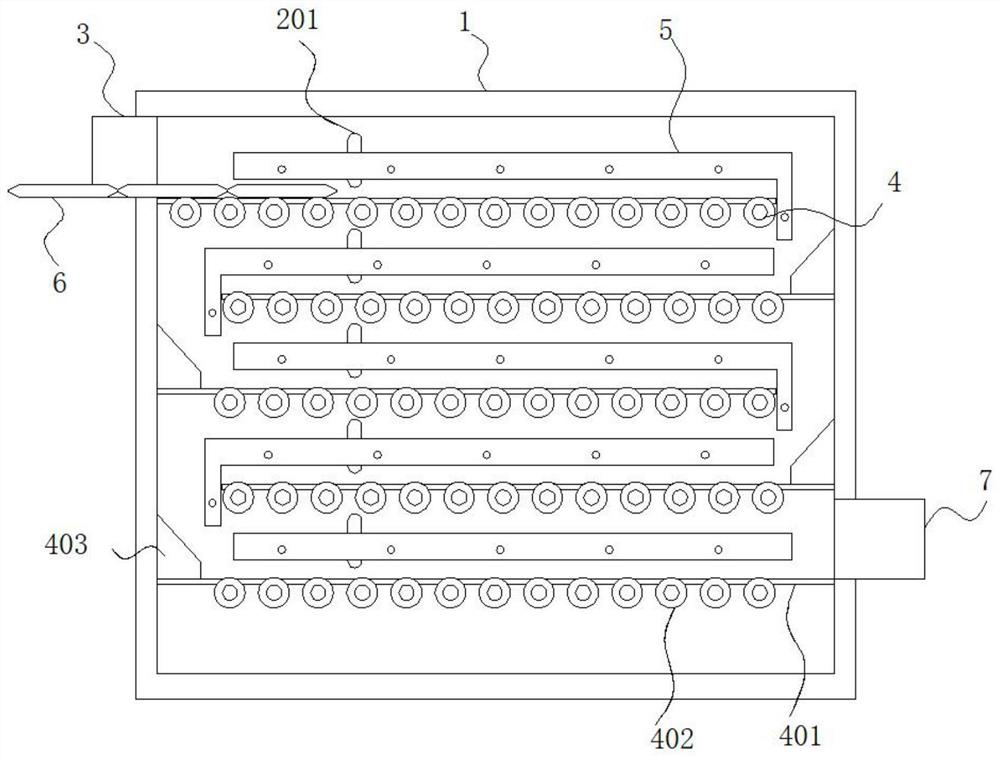

[0034] One end of the rolling roller 402 protruding from the sterilization box 1 is equipped with a chain transmission mechanism. The chain transmission mechanism includes a chain of an annular structure. The chain link has a sprocket fixedly sleeved with the rolling roller 402. The driving sprocket, the driving sprocket is equipped with a motor;

Embodiment 3

[0036] One side of the sterilization box 1 is equipped with a control box, the inside of the control box is equipped with a controller, and one side of the control box is equipped with a power supply interface, a data interface, a display screen and a ship type switch. The controller adopts an ARM microcontroller, and the controller is connected to the first A proximity switch, a proximity switch, a vacuum pump, a motor, a linear motor, a power interface, a data interface, a display screen and a ship type switch are electrically connected.

[0037] Working principle: when in use, the chain-shaped sterilization bag 6 storing spore powder is pushed from the opening of the feeding pipe 3 to the inside of the sterilization box 1, and then installed on the rolling roller on the top conveying assembly 4 The chain driving mechanism at the end of 402 drives the rolling roller 402, and the sterilization bag 6 moves along the length direction of the supporting plate 401 under the drive o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com