Anti-corrosion construction device and anti-corrosion construction method for the integral inner wall of penstock steel pipes in hydropower stations

A pressure steel pipe and construction device technology, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of damage to the anti-corrosion layer, increased scaffolding, and time-consuming anti-corrosion layer, etc., to achieve high wear resistance Erosion resistance, shortened construction period, and excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

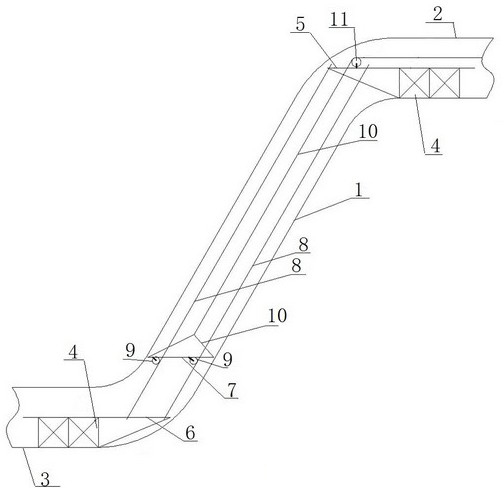

[0026] see figure 1 , an anticorrosion construction device and anticorrosion construction method for the overall inner wall of a penstock steel pipe of a hydropower station, the specific steps are as follows:

[0027] 1. According to the size of the internal surface area of the pressure steel pipe, process and produce internal anti-corrosion ceramic rods or ceramic powder anti-corrosion materials;

[0028] 2. Make and install the upper console support and upper console 5, the lower console bracket and the lower console 6, the mobile console 7, the independent guide rail 8 and the traction wire rope 10 according to the length and inclination of the penstock inclined section 1, so that the upper The operating platform 5, the lower operating platform 6, and the mobile operating platform 7 are in a horizontal state, and the inclination of the independent guide rail 8 is the same as that of the inclined section 1 of the penstock. The mobile console roller 9 matches the independe...

Embodiment 2

[0033] see figure 1 , an anticorrosion construction device and anticorrosion construction method for the overall inner wall of a penstock steel pipe of a hydropower station, the specific steps are as follows:

[0034] 1. According to the size of the internal surface area of the pressure steel pipe, process and produce internal anti-corrosion tungsten carbide rod anti-corrosion materials;

[0035] 2. Make and install the upper console support and upper console 5, the lower console bracket and the lower console 6, the mobile console 7, the independent guide rail 8 and the traction wire rope 10 according to the length and inclination of the penstock inclined section 1, so that the upper The operating platform 5, the lower operating platform 6, and the mobile operating platform 7 are in a horizontal state, and the inclination of the independent guide rail 8 is the same as that of the inclined section 1 of the penstock. The mobile console roller 9 matches the independent guide r...

Embodiment 3

[0040] see figure 1 , an anticorrosion construction device and anticorrosion construction method for the overall inner wall of a penstock steel pipe of a hydropower station, the specific steps are as follows:

[0041] 1. According to the size of the internal surface area of the pressure steel pipe, process and produce internal anti-corrosion thermal spray zinc wire and solvent-free epoxy anti-corrosion and wear-resistant coating;

[0042] 2. Make and install the upper console support and upper console 5, the lower console bracket and the lower console 6, the mobile console 7, the independent guide rail 8 and the traction wire rope 10 according to the length and inclination of the penstock inclined section 1, so that the upper The operating platform 5, the lower operating platform 6, and the mobile operating platform 7 are in a horizontal state, and the inclination of the independent guide rail 8 is the same as that of the inclined section 1 of the penstock. The mobile conso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com