Method for preparing high-tap-density silver flake

A technology of flake silver powder and tap density, which is applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

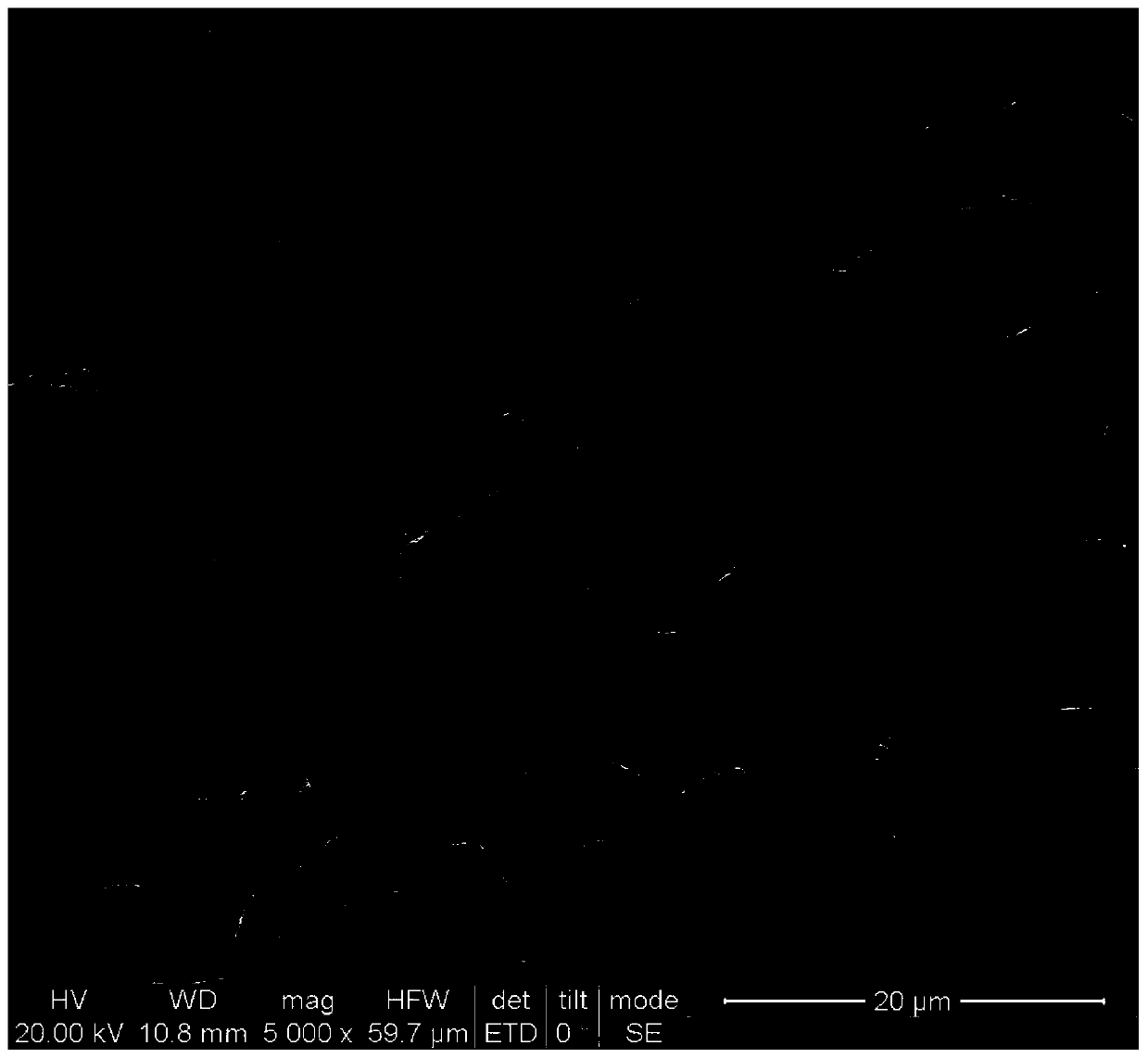

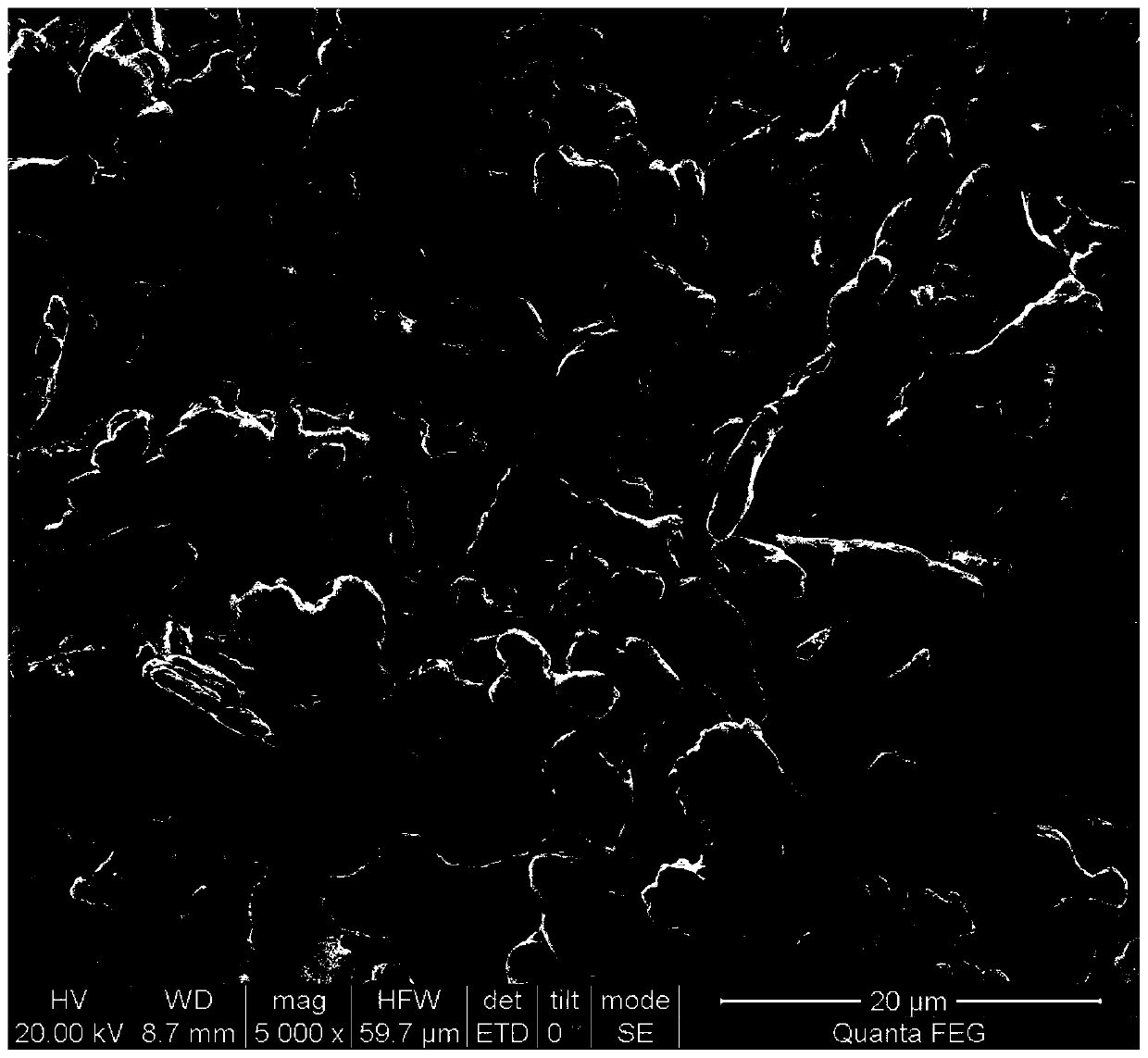

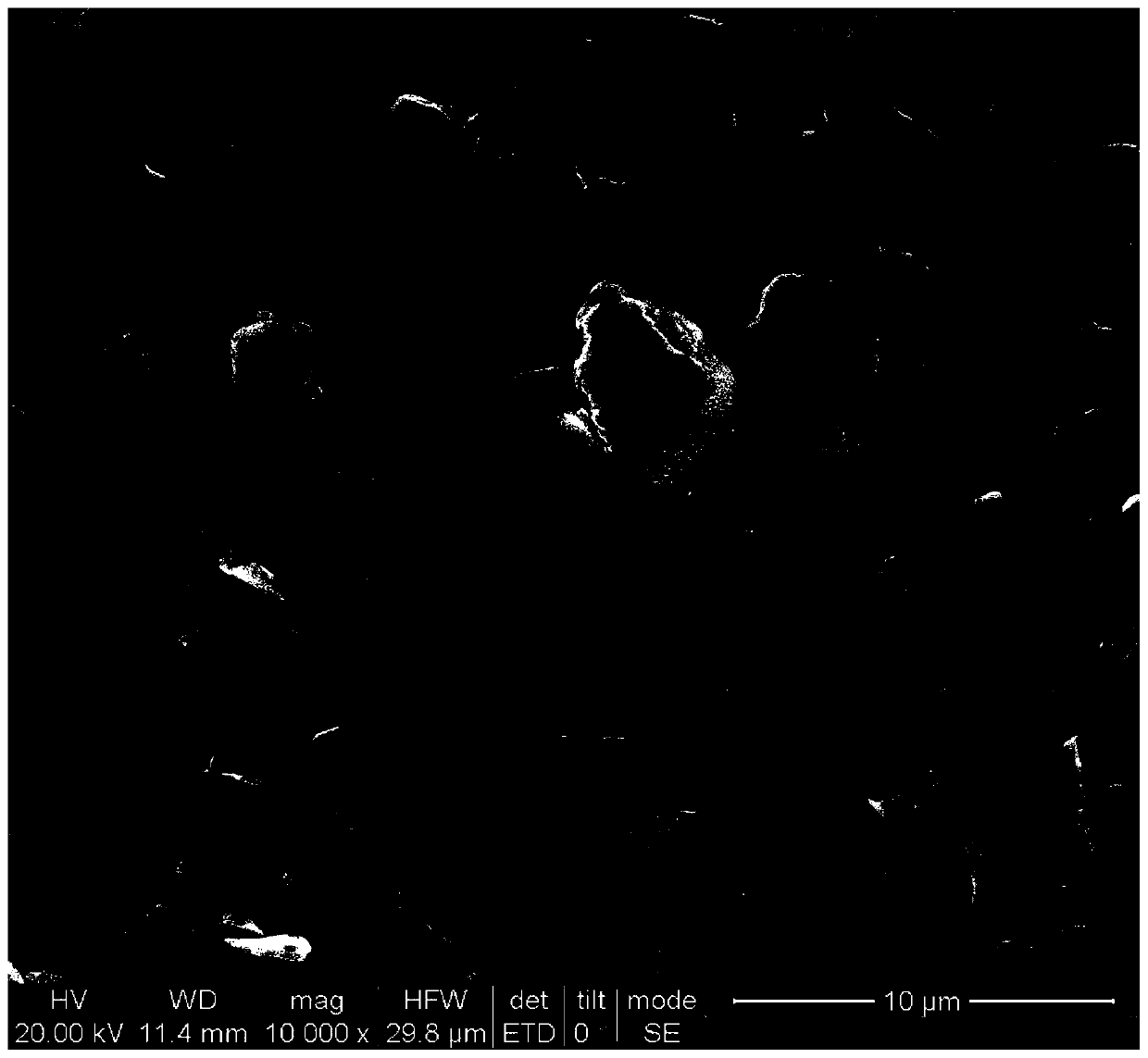

Image

Examples

Embodiment

[0081] A preparation method of high tap density flaky silver powder, comprising the following steps:

[0082] Step 1: Prepare a solution, including silver nitrate solution A, reducing agent solution B, regulator solution C and dispersant solution D;

[0083] Step 2: Reduction reaction, under high-speed stirring, slowly add the regulator solution C to the silver nitrate solution A, and immediately add the reducing agent solution B quickly, and quickly add the dispersant within 10 seconds after the reducing agent solution B is added For solution D, adjust the heating temperature in stages after adding, and keep the temperature between 50°C and 90°C for reaction;

[0084] Step 3: After the reduction reaction in step 2 is completed, remove the supernatant after the reaction by sedimentation, transfer the remaining part to the cleaning bucket, backwash with deionized water until the conductivity is ≤ 20μS / cm, and remove the supernatant by suction filtration liquid;

[0085] Step ...

Embodiment 1

[0094] A preparation method of high tap density flaky silver powder, comprising the following steps:

[0095] Preparation of silver nitrate solution

[0096] Accurately weigh 1kg of silver nitrate, dissolve it in 20L of deionized water, and prepare a silver nitrate solution with a mass concentration of 4.76%wt, control the temperature in a water bath at 22°C-24°C, stir for 15min, and prepare silver nitrate solution A;

[0097] Preparation of reducing agent solution

[0098] Accurately weigh 0.75kg of ascorbic acid and 0.01kg of hydrazine hydrate, dissolve them in 5L of deionized water, control the temperature of the solution at 22°C to 24°C, and stir for 30min to prepare reducing agent solution B;

[0099] Preparation of conditioner solution

[0100] Dissolve 410g of sodium hydroxide in 1L of deionized water and adjust the temperature to 22-24°C to prepare conditioner solution C;

[0101] Preparation of dispersant solution

[0102] Add 20g of polyvinyl alcohol into 0.5L of...

Embodiment 2

[0113] A preparation method of high tap density flaky silver powder, comprising the following steps:

[0114] Preparation of silver nitrate solution

[0115]Accurately weigh 1kg of silver nitrate, dissolve it in 15L of deionized water, and prepare a silver nitrate solution with a mass concentration of 6.25%wt, control the temperature in a water bath at 35°C to 37°C, and stir for 15min to prepare silver nitrate solution A;

[0116] Preparation of reducing agent solution

[0117] Accurately weigh 0.5kg of glucose and 0.12kg of acetaldehyde, dissolve them in 5L of deionized water, control the temperature of the solution at 35°C to 40°C, and stir for 30min to prepare reducing agent solution B;

[0118] Preparation of conditioner solution

[0119] Dissolve 480g of sodium carbonate in 1L of deionized water and adjust the temperature to 40-45°C to prepare conditioner solution C;

[0120] Preparation of dispersant solution

[0121] Add 20g of polyacrylic acid into 0.5L of deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com