Steering-by-wire system and control method thereof

A technology of steer-by-wire and steering column, which is applied to steering mechanism, electric steering mechanism, power steering mechanism, etc., which can solve the problems of high energy consumption and slow response speed, and achieve the effect of safe steering and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

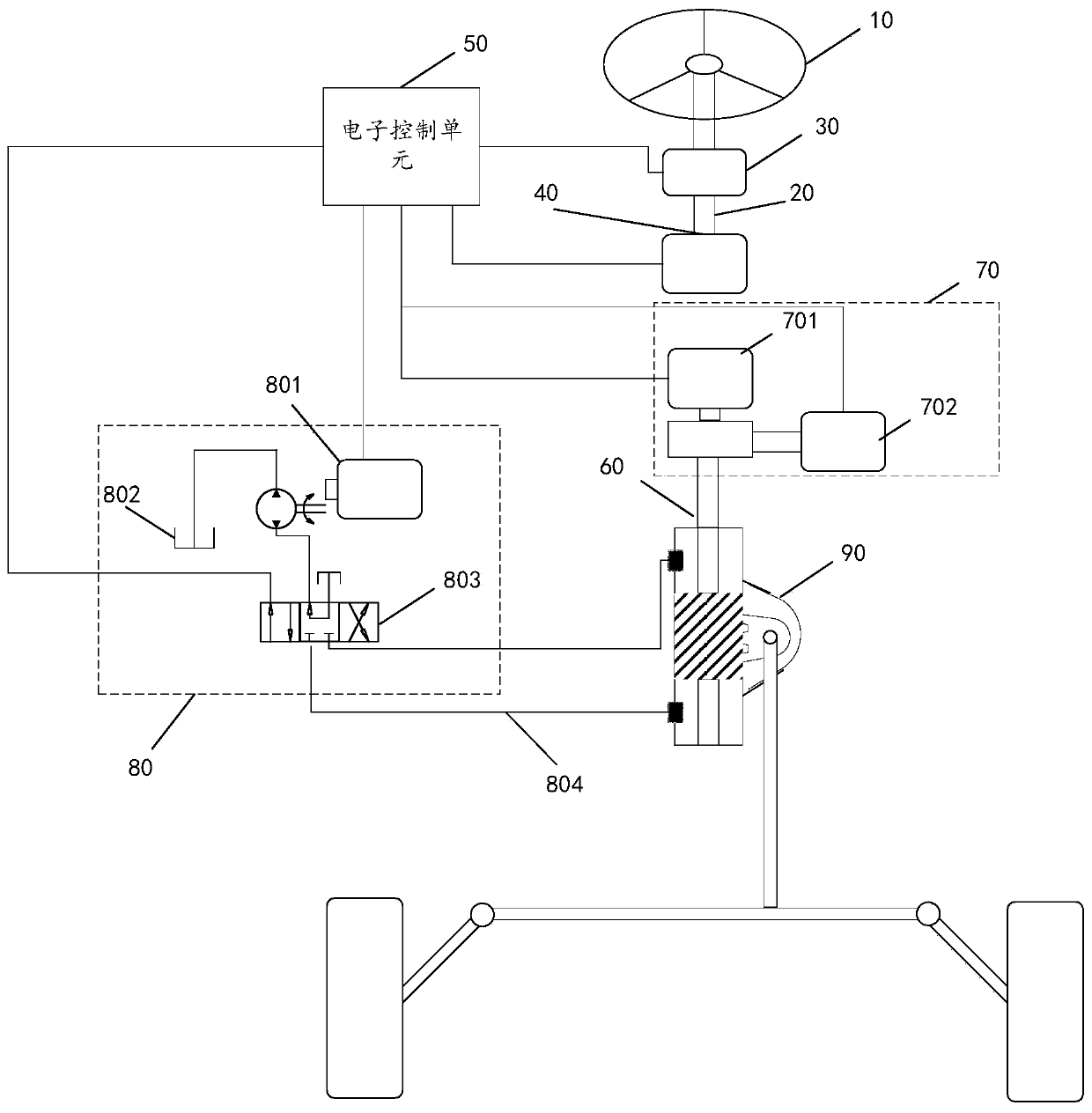

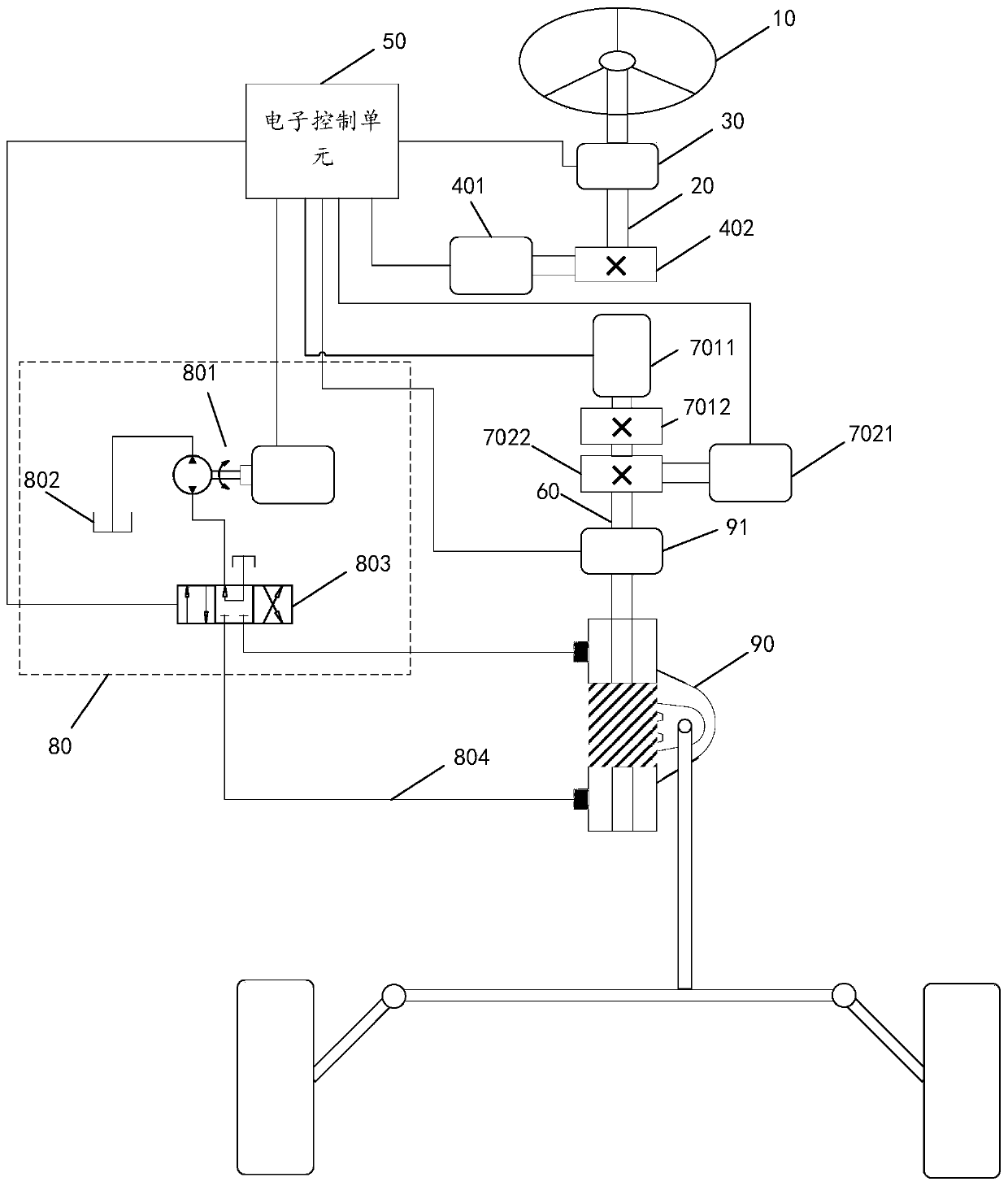

[0040] Such as figure 1 As shown, the present application provides a steer-by-wire system, which includes a steering wheel 10, a first steering column 20, a first torque angle sensor 30, a road feeling feedback unit 40, an electronic control unit 50, and a second steering column 60 , motor assist unit 70, hydraulic assist unit 80 and recirculating ball hydraulic power steering 90, the motor assist unit 70 includes a first motor steering assist unit 701 and a second motor steering assist unit 702, the hydraulic assist unit 80 includes an electro-hydraulic Pump 801, oil tank 802, electromagnetic reversing valve 803 and oil pipe 804; the steering wheel 10 is connected to the torque input end of the first steering column 20, and the first torque angle sensor 30 is sleeved on the first steering column 20, the road The sense feedback unit 40 is connected to the torque output end of the first steering column 20, the first motor steering assist unit 701 and the second motor steering a...

no. 2 example

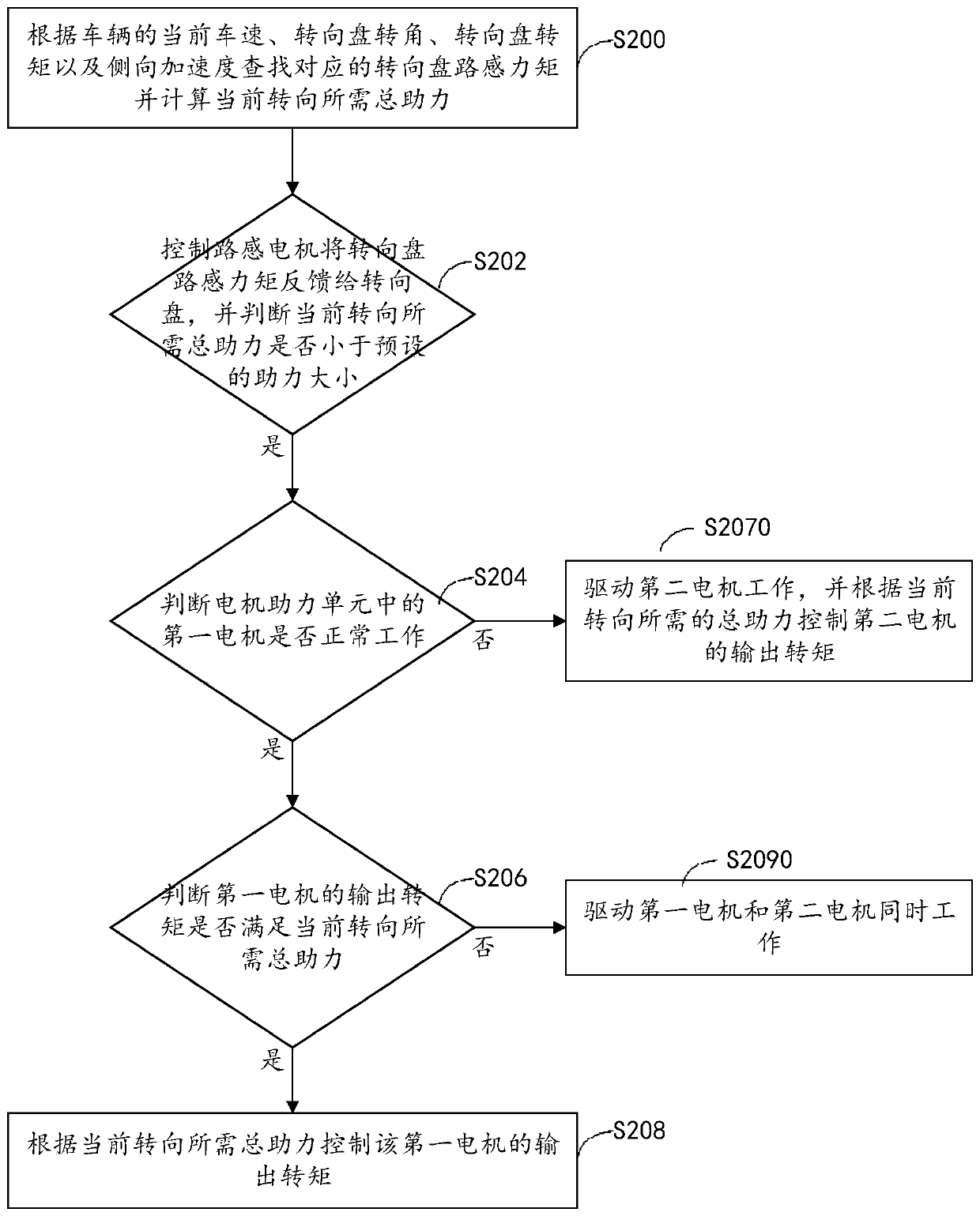

[0057] Such as image 3 As shown, the present application provides a steer-by-wire control method, which can be applied to the electronic control unit in the aforementioned first embodiment, and the method specifically includes the following steps:

[0058] Step S200: According to the vehicle's current vehicle speed, steering wheel angle, steering wheel torque and lateral acceleration, find the corresponding steering wheel torque and calculate the total power assistance required for the current steering.

[0059] Step S202: Control the road-sensing motor to feed back the road-sensing torque of the steering wheel to the steering wheel, and judge whether the total power required for the current steering is less than the preset power assist, if yes, go to step S204, if not, go to step S2050 .

[0060] Step S204: Determine whether the first motor in the motor assisting unit is working normally. The motor assisting unit includes the first motor and the second motor. If yes, go to ...

no. 3 example

[0086] Figure 6 A schematic structural block diagram of the steer-by-wire control device provided by the present application is shown. It should be understood that the device is different from the above-mentioned Figure 3 to Figure 6 Corresponding to the method embodiment in the second embodiment, the steps involved in the method in the second embodiment can be performed. The specific functions of the device can refer to the above description. To avoid repetition, the detailed description is appropriately omitted here. The device includes at least one software function module that can be stored in a memory in the form of software or firmware (firmware) or solidified in an operating system (operating system, OS) of the device. Specifically, the device includes: a calculation module 300 for finding the corresponding feedback torque according to the current vehicle speed, steering wheel angle, steering wheel torque and lateral acceleration of the vehicle and calculating the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com