Water area anti-tearing rope net device and assembly method thereof

An assembly method and anti-biting technology, applied in circuit devices, battery circuit devices, lifesaving in water, etc., can solve problems such as high cost, hidden dangers of water safety, violation of social background, etc., and achieve light texture, reduced possibility, and structural strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

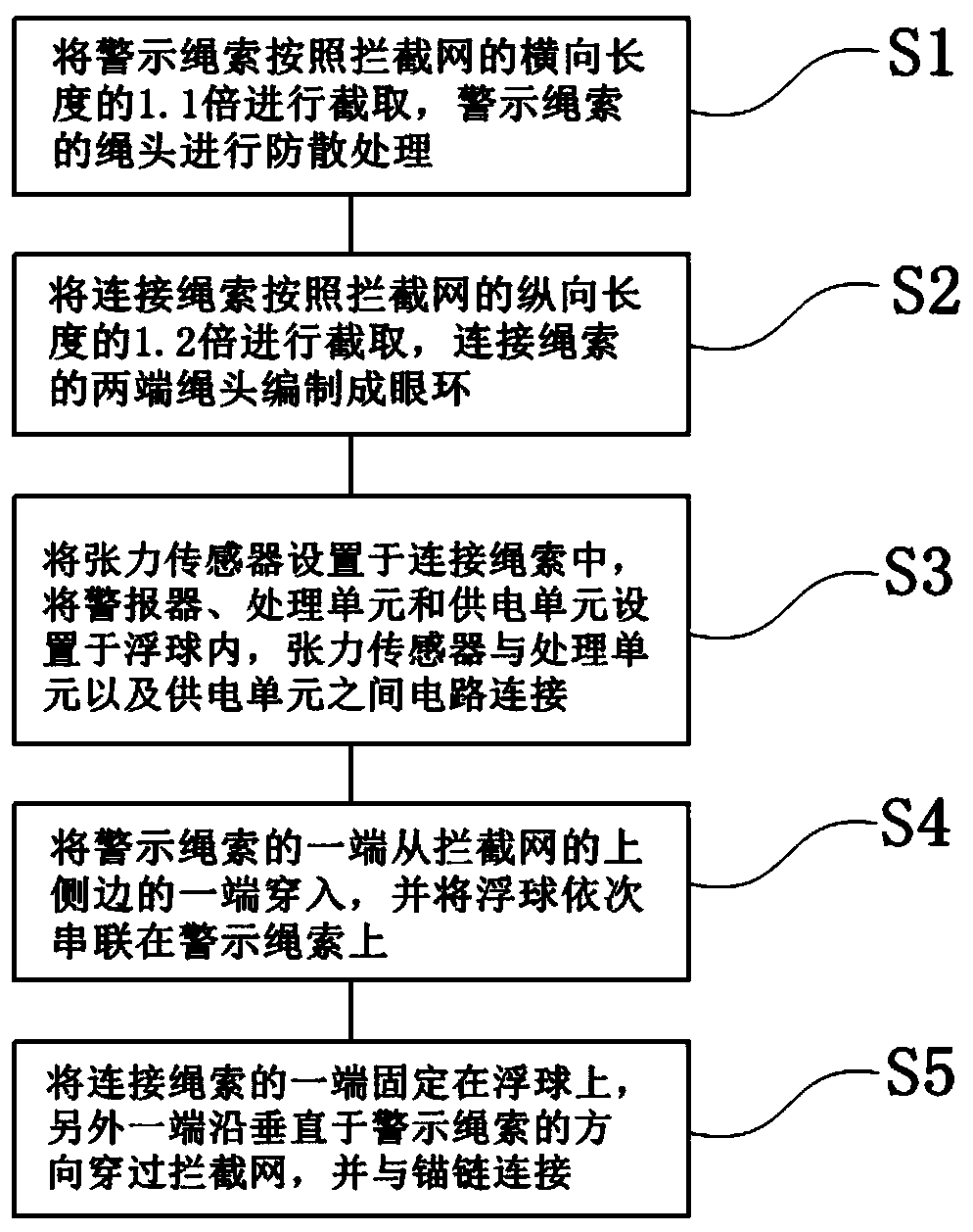

[0073] In the assembly method of the anti-tearing rope net device for water areas disclosed in Embodiment 1 of the present invention, the method for making the warning rope includes:

[0074] Step A1: Select ultra-high molecular weight polyethylene fibers with a specification of 1600D.

[0075] Step A2: Take 18 ultra-high molecular weight polyethylene fibers and form a strand, and twist during the doubling process.

[0076] Step A3: In the process of doubling and twisting the strands, carry out online coating with high dye-uptake property, and paint the strands of the ultra-high molecular weight polyethylene fiber rope in orange.

[0077] Step A4: Use a 320 braiding machine to braid 6 strands of S twist and 6 strands of Z twist into a rope with a pitch of 10 times.

[0078] In the assembly method of the anti-tearing rope net device for water areas disclosed in Embodiment 1 of the present invention, the production method of the intercepting net includes:

[0079] Step B1: Sel...

Embodiment 2

[0090] In the assembly method of the anti-tearing rope net device for water areas disclosed in Embodiment 2 of the present invention, the method for making the warning rope includes:

[0091] Step A1: Select polyester fiber with a specification of 3000D.

[0092] Step A2: Take 10 polyester fibers and form a strand, and twist them during doubling.

[0093] Step A3: In the process of doubling and twisting the strands, carry out in-line coating with high dye-uptake property, and paint the strands of the polyester fiber rope yellow.

[0094] Step A4: Use a 320 braiding machine to braid 6 strands of S twist and 6 strands of Z twist into a rope with a pitch of 10 times.

[0095] In the assembling method of the anti-tearing rope net device in water area disclosed in Embodiment 2 of the present invention, the production method of the intercepting net includes:

[0096] Step C1: Select ultra-high molecular weight polyethylene fibers with a specification of 1600D.

[0097] Step C2: m...

Embodiment 3

[0108] In the assembly method of the anti-tearing rope net device for water areas disclosed in Embodiment 2 of the present invention, the method for making the warning rope includes:

[0109] Step A1: Select polyester fibers with a specification of 800D and ultra-high molecular weight polyethylene fibers with a specification of 1600D.

[0110] Step A2: Use 10 polyester fibers and 20 ultra-high molecular weight polyethylene fibers to form a strand, feed the polyester fibers and ultra-high molecular weight polyethylene fibers to the twisting equipment at the same time, and install a branch line in the twisting equipment, so that In the mixed rope strands, the polyester fiber is kept in the inner layer, and the ultra-high molecular weight polyethylene fiber is wrapped in the outer layer, and the twist is twisted during the doubling process.

[0111] Step A3: In the strand doubling and twisting process, high dye-uptake online coating is performed, and the mixed fiber strands are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com