Method and system for automatic chlorine and hydrogen proportioning control of hydrogen chloride synthesis furnace, and synthesis furnace

An automatic proportioning and control method technology, applied in the direction of hydrogen chloride preparation, chlorine/hydrogen chloride, etc., can solve the problems of hydrogen containing condensed water that easily interferes with measurement, high labor intensity, and high accident rate, so as to solve the risk of excessive chlorine gas and reduce manpower The effect of putting into use and reducing the labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

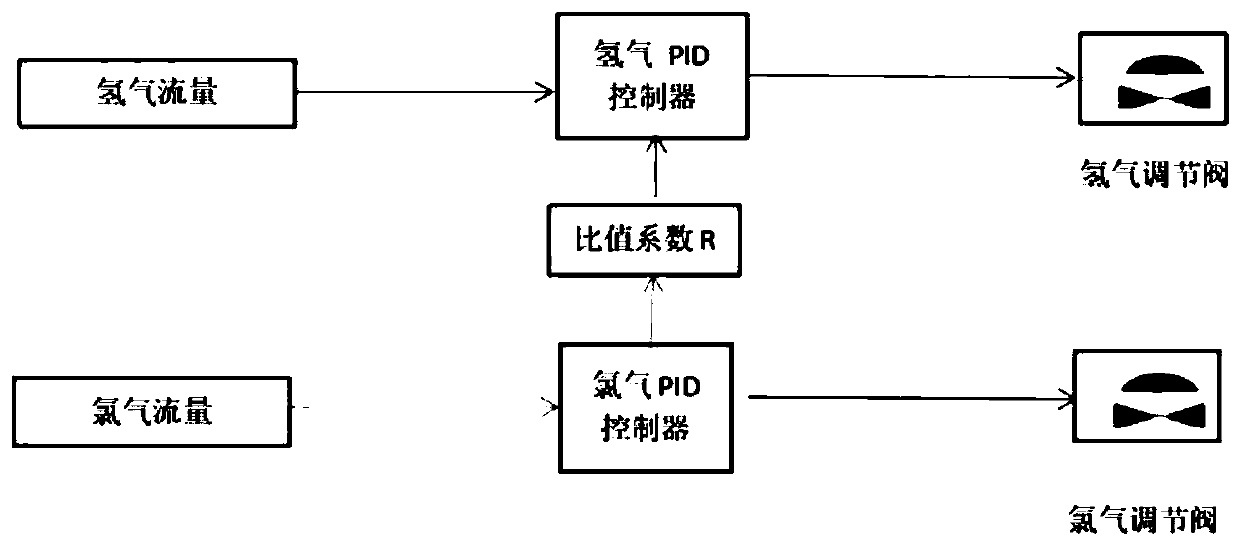

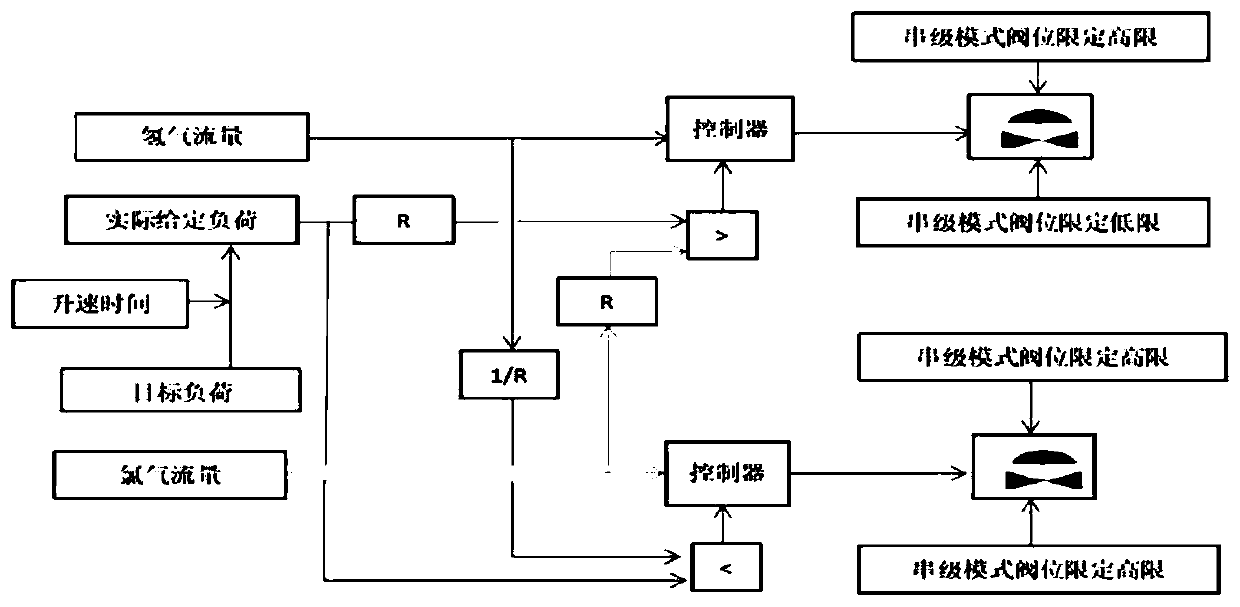

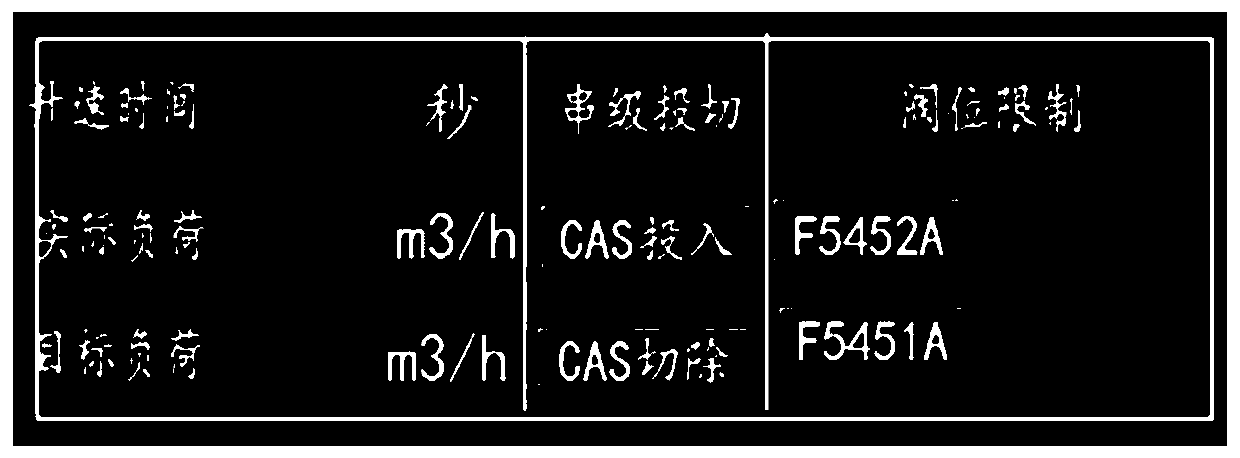

[0042] like figure 2 As shown, Embodiment 1 of the present disclosure provides a method for controlling the automatic proportioning of chlorine and hydrogen in a hydrogen chloride synthesis furnace. The chlorine flow is limited by low-level selection, and the hydrogen flow is limited by high-level selection. When the gas flow of hydrogen fluctuates and fluctuates When the amount is lower than the first hydrogen setting threshold or the gas flow of chlorine fluctuates and the fluctuating amount is lower than the first chlorine setting threshold, the hydrogen flow and the chlorine flow are mutually sensed and locked through high-level selection and low-level selection. When the flow disturbance occurs, ensure that the hydrogen ratio is excessive and greater than the safe lower limit, and free chlorine is not generated.

[0043] When the load is increased, the chlorine flow is restricted by the hydrogen flow and will not increase. When the hydrogen setting value and the load tar...

Embodiment 2

[0063] Embodiment 2 of the present disclosure provides an automatic proportioning control system for hydrogen chloride in a hydrogen chloride synthesis furnace, which at least includes a low-level selector, a high-level selector, a first controller, and a second controller;

[0064] The low-level selector is used to limit the flow of chlorine gas, and the high-level selector is used to limit the flow of hydrogen gas. When the gas flow of hydrogen fluctuates and the fluctuation amount is lower than the first hydrogen set threshold or the gas flow of chlorine fluctuates and When the fluctuation amount is lower than the first set threshold of chlorine gas, the hydrogen flow and the chlorine flow are sensed and locked by the high-level selection and the low-level selection, so that the hydrogen ratio is excessive and greater than the safe lower limit when the load adjustment and flow disturbance occur, and no free radicals are generated. chlorine;

[0065] When the load is increas...

Embodiment 3

[0075] Embodiment 3 of the present disclosure provides a hydrogen chloride synthesis furnace, using the hydrogen chloride synthesis furnace described in Embodiment 1 of the present disclosure. The automatic proportioning control method of chlorine and hydrogen is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com