Method for making concrete by using calcareous sand

A technology of concrete and calcium, which is applied in the field of concrete materials, can solve the problems of difficulty in obtaining materials, increase the cost and difficulty of engineering construction, and high cost of land river sand transportation, and achieve the effect of increasing strength and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

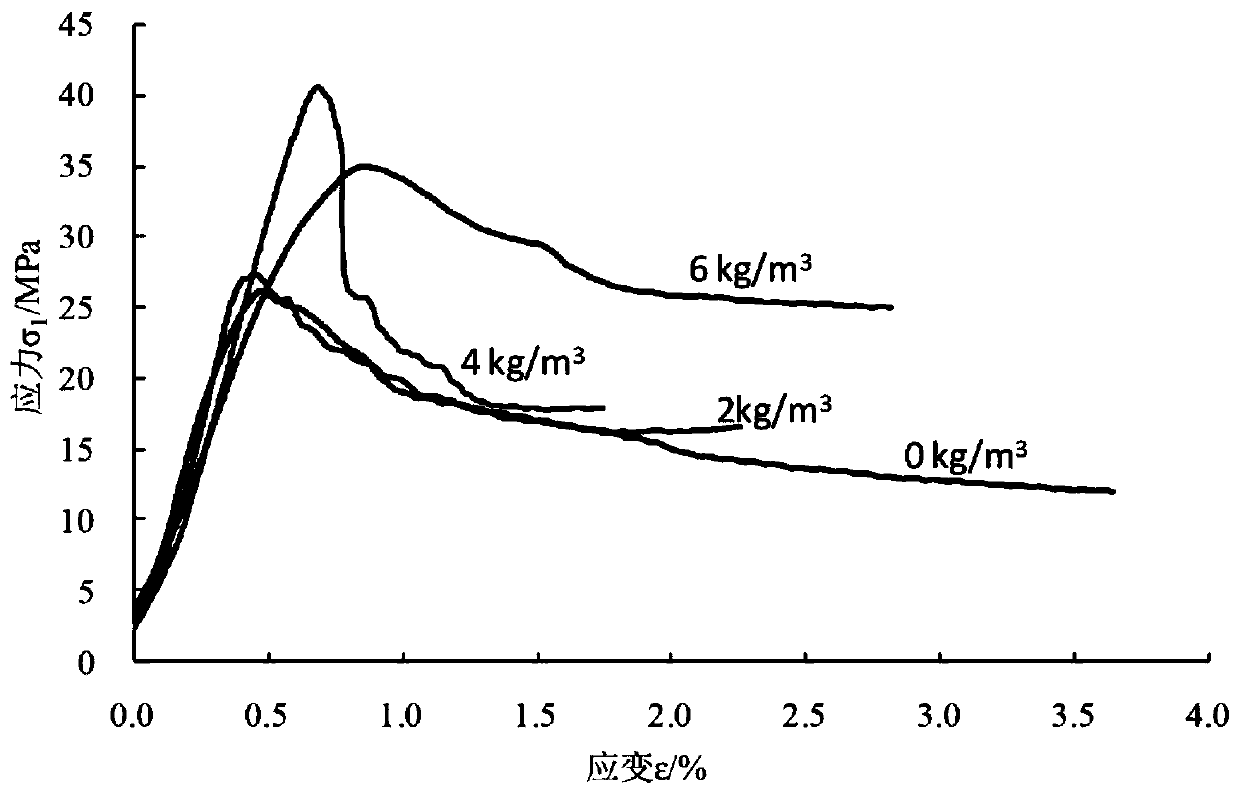

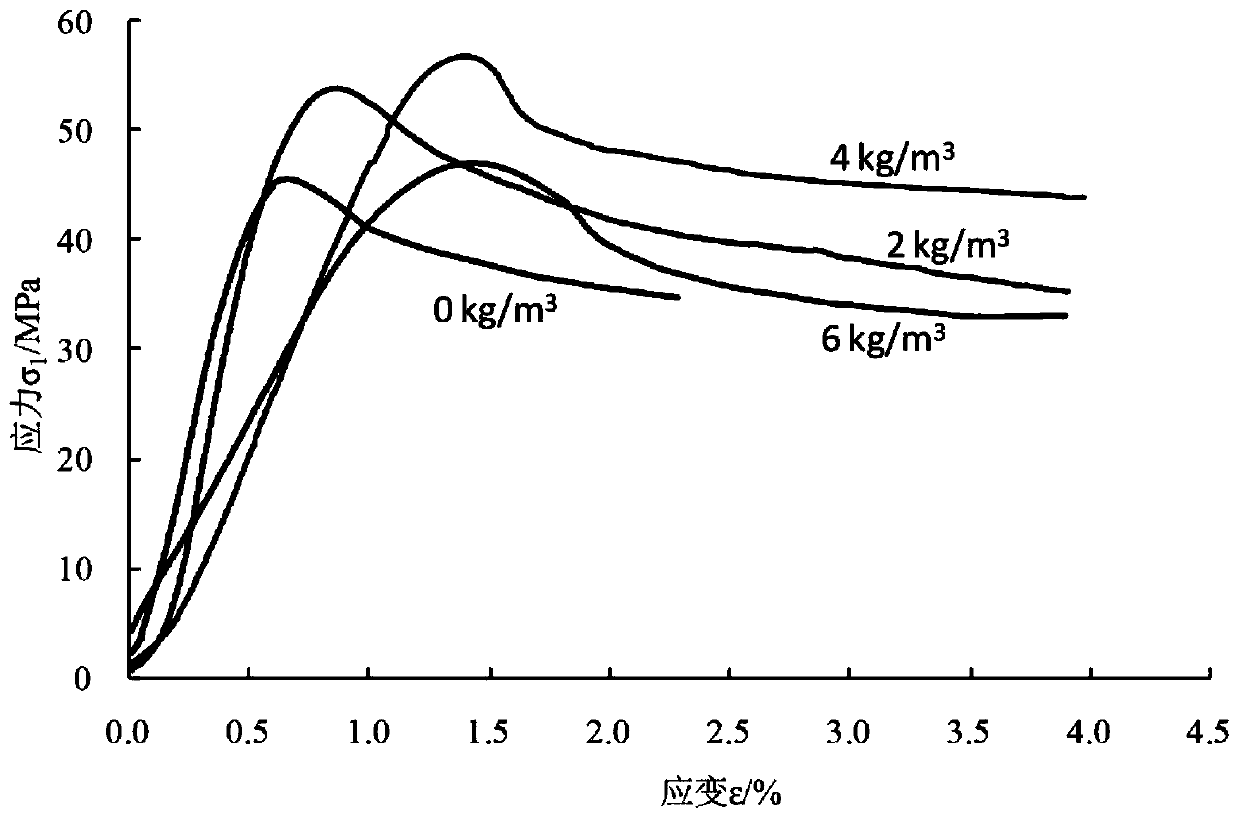

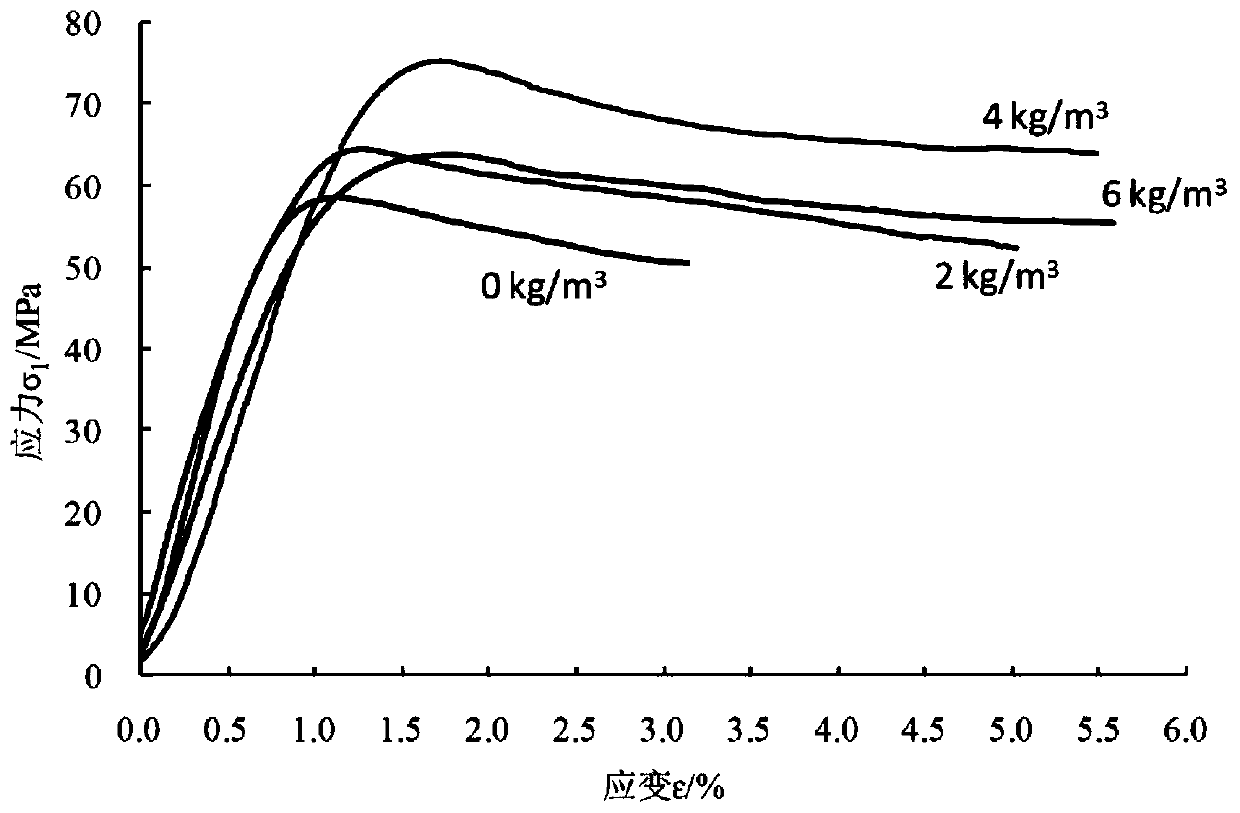

[0032] The target preparation of C30 concrete is calculated and determined according to the "Concrete Mix Proportion Design Regulations (JGJ55-2011)".

[0033] Calculated: water-binder ratio: 0.56. The slump is 75-90mm, and the water consumption of concrete can be calculated: 215kg / m 3 .

[0034] Cement amount = water amount ÷ water-binder ratio = 385kg / m 3 . The sand rate is 38%, 1m 3 The quality of concrete is taken as 2350kg, and fine aggregate = 665kg, coarse aggregate = 1084kg. Table 1 shows the amount of calcareous sand concrete material per cubic meter. Among them, group A was used as the reference group.

[0035] serial number Cement / kg water / kg Sand / kg Stone / kg fiber / kg A 385 215 665 1084 0 B 385 215 665 1084 2 C 385 215 665 1084 4 D 385 215 665 1084 6

[0036] Table 1

[0037] Make a 150mm×150mm×150mm standard sample. In order to make the basalt fiber evenly distributed in the concrete sample, add st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com