Zinc titanate ceramic precursor slurry and method for preparing zinc titanate ceramic through 3D printing

A ceramic precursor, zinc titanate technology, applied in the field of ceramics, can solve the problem of unsuitable rheological properties of sol-gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a zinc titanate ceramic precursor slurry, which is prepared according to the following steps:

[0033] Preparation of titanium-containing source solution: Add 0.6g of polyvinylpyrrolidone (PVP, molecular weight 55000) into 8mL of absolute ethanol, stir until completely dissolved, then add 12.5mL of bis(acetylacetonate) diisopropyl titanate ( 75wt.% isopropanol solution), mixed to obtain titanium-containing source solution;

[0034] Preparation of zinc source solution: Add 1.5mL 28% ammonia water and 1.8mL deionized water into 8mL absolute ethanol, stir well, then add 0.5g zinc oxide powder, stir until zinc oxide reacts with ammonia water until completely dissolved, mix Obtain zinc source solution;

[0035] Preparation of the slurry: adding the zinc-containing source solution into the titanium-containing source solution, heating and stirring in a water bath at 80° C. for about 1 to 2 hours until a gel is formed.

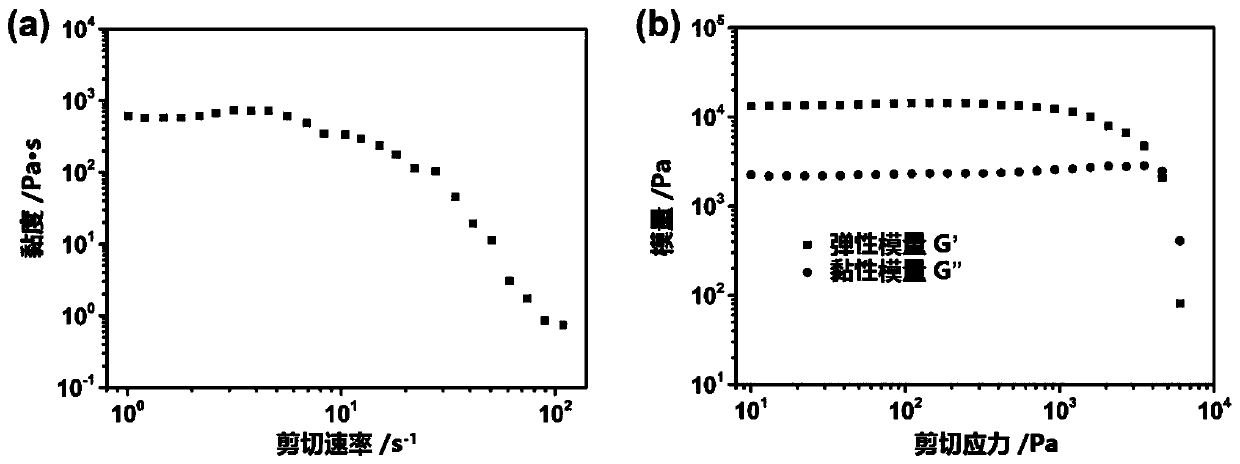

[0036] figure 1 It is the rhe...

Embodiment 2

[0038] This embodiment provides a zinc titanate ceramic, prepared according to the following steps:

[0039] Get the zinc titanate ceramic precursor slurry prepared in Example 1 and put it into the barrel to be printed;

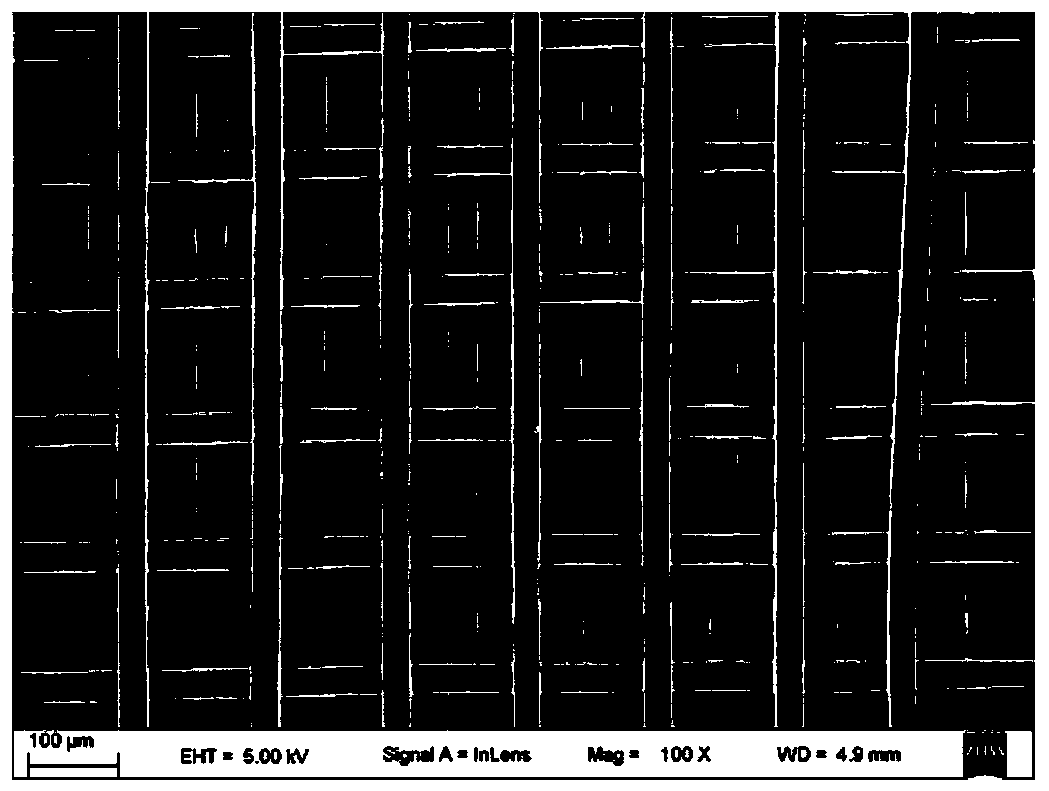

[0040] 3D printing molding: write the G code program of the wood pile structure, set the distance between the medium rods to 250μm, select the glass needle with a diameter of 60μm, set the pressure to 85psi, and the printing speed to 5mm / s, for the sol-gel zinc titanate ceramic precursor Carry out fine direct writing 3D printing molding of the body slurry to obtain the embryo body;

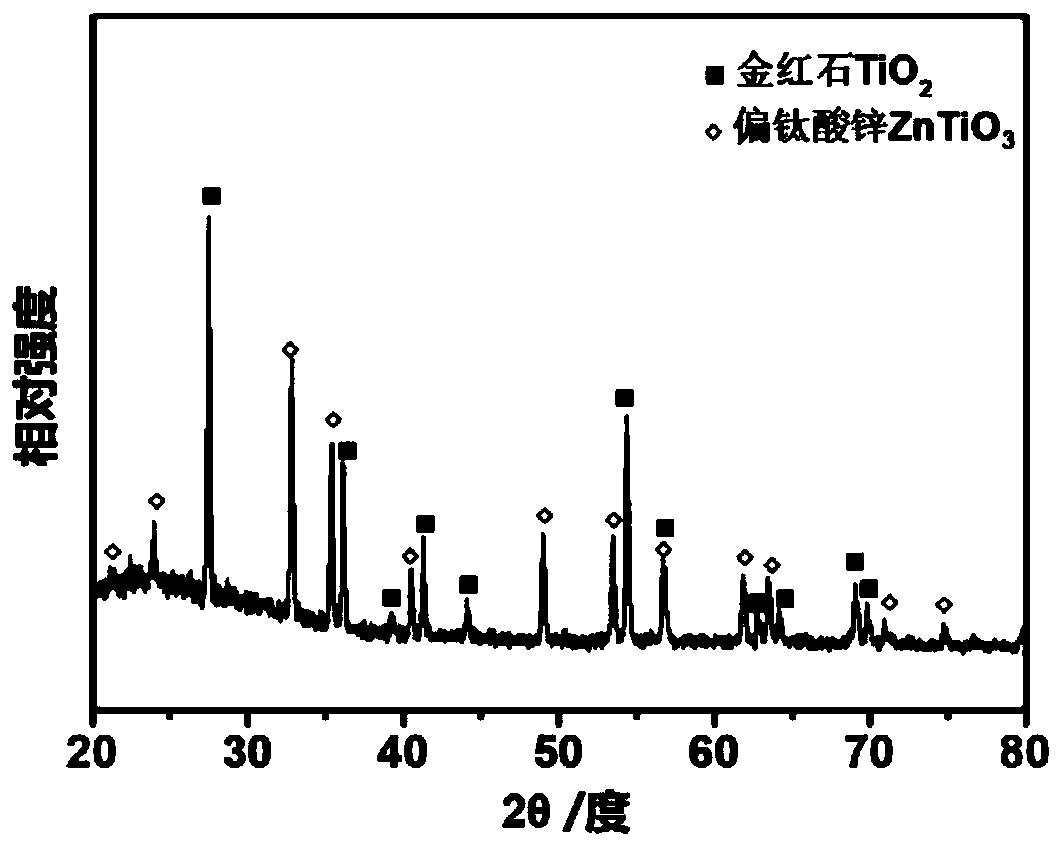

[0041] Calcination treatment: Sinter the above-mentioned green body by adopting a multi-step heat preservation sintering process, specifically: raise the temperature to 450°C at a rate of 0.5°C / min for 4 hours, then raise the temperature to 600°C at a rate of 0.5°C / min for 4 hours, and then The temperature was raised to 850°C at a rate of 2°C / min for 5 hours, and finally cooled ...

Embodiment 3

[0046] This embodiment provides a zinc titanate ceramic, prepared according to the following steps:

[0047] Preparation of titanium-containing source solution: Add 0.6g of polyvinylpyrrolidone (PVP, molecular weight 55000) into 8mL of absolute ethanol, stir until completely dissolved, then add 12.5mL of bis(acetylacetonate) diisopropyl titanate ( 75wt.% isopropanol solution), mixed to obtain titanium-containing source solution;

[0048] Preparation of zinc-containing source solution: Add 5mL 28% ammonia water and 1.8mL deionized water into 12mL absolute ethanol, stir evenly, then add 2.09g zinc oxide powder, stir until zinc oxide and ammonia water react until completely dissolved, and mix to obtain Zinc source solution;

[0049] Preparation of the zinc titanate ceramic precursor slurry: Add the zinc-containing source solution to the titanium-containing source solution, heat, stir and evaporate in a water bath at 80°C for about 2 to 3 hours until a gel is formed. At this time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com