A Supporting Method for Tunnel Corrugated Steel Double Layer Primary Lining

A corrugated steel, initial support technology, applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of excessive deformation of initial support, troublesome secondary lining construction, difficult repair, etc., to reduce environmental impact, green Construction, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

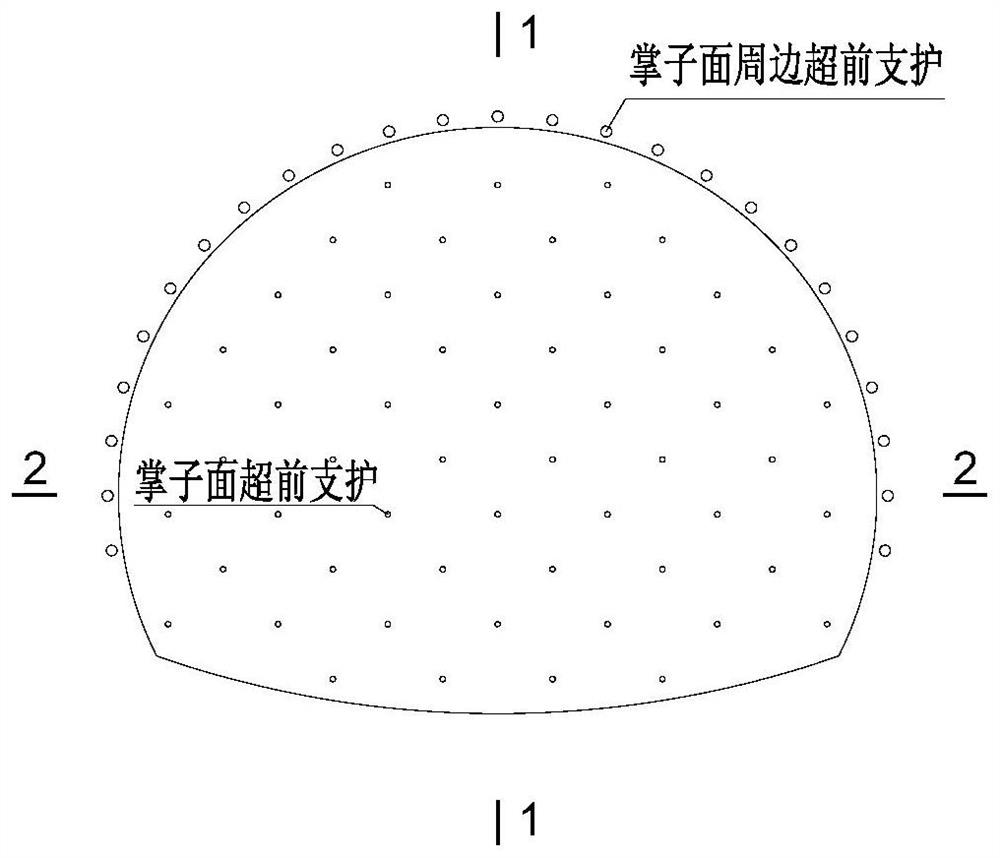

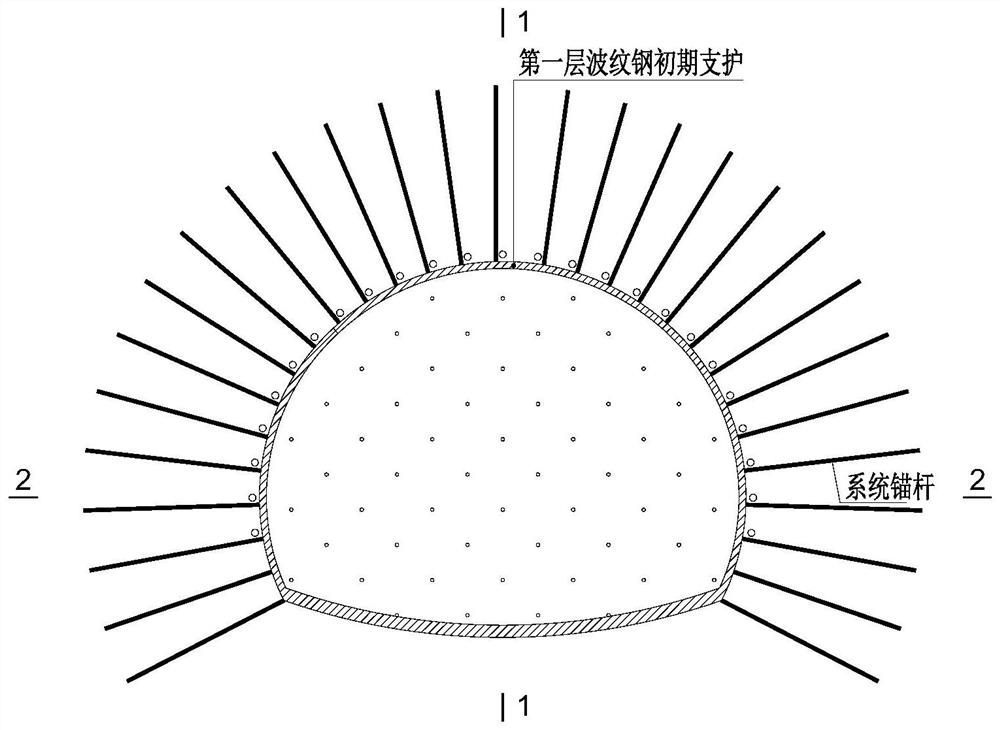

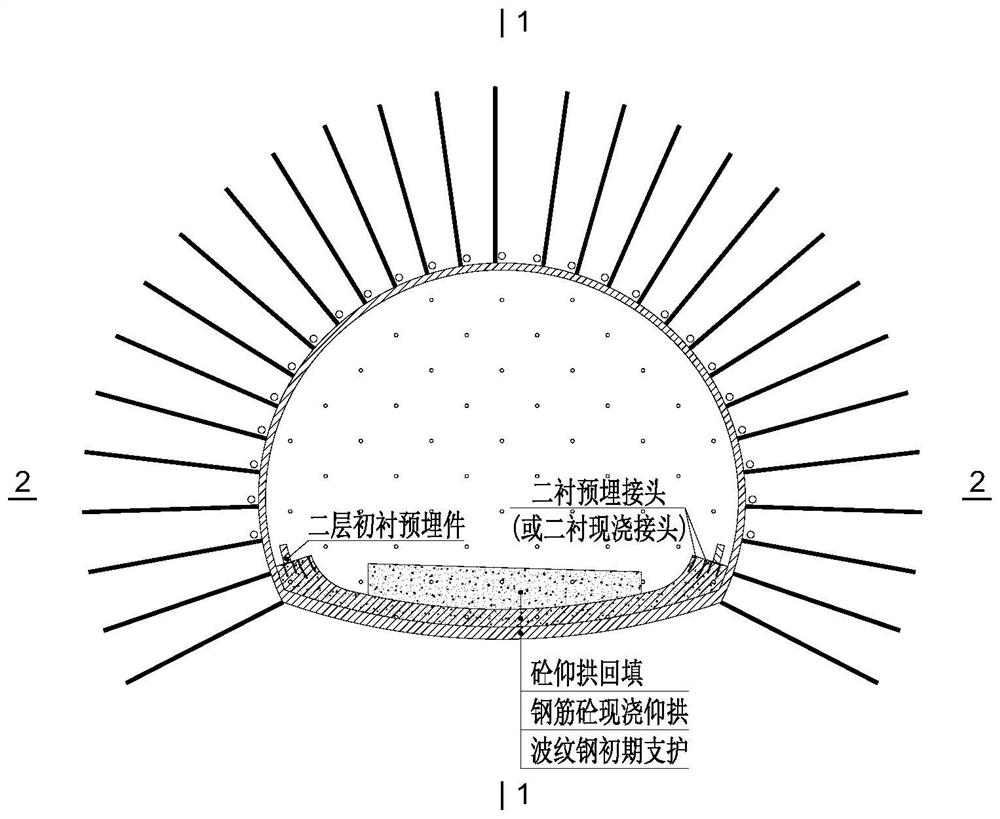

[0038] Figure 1 to Figure 7 Shown is the cross-sectional view of the whole process of tunnel construction, Figure 8 ~ Figure 9 It is a schematic diagram of the vertical section and a schematic diagram of the tunnel construction process.

[0039] The invention provides a tunnel corrugated steel double-layer initial lining support method and structure. The support method needs to be equipped with a bolter drilling rig, an intelligent assembly of initial support and an intelligent grouting trolley behind the wall, an intelligent assembly of the second lining and an intelligent The grouting trolley behind the wall realizes the rapid, mechanized and intelligent construction of the full section of the tunnel, improves the modernization level of tunnel construction, improves construction efficiency, saves project cost, reduces environmental impact, and realizes green construction. It mainly includes the following steps:

[0040] Step 1: Drilling with bolts, constructing the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com