Motor rotor, processing method thereof and synchronous reluctance motor

A technology for motor rotors and processing methods, which is applied in the manufacture of squirrel cage rotors, stator/rotor bodies, electrical components, etc., and can solve problems such as inability to improve motor performance, increase motor air gap, and reduce motor power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

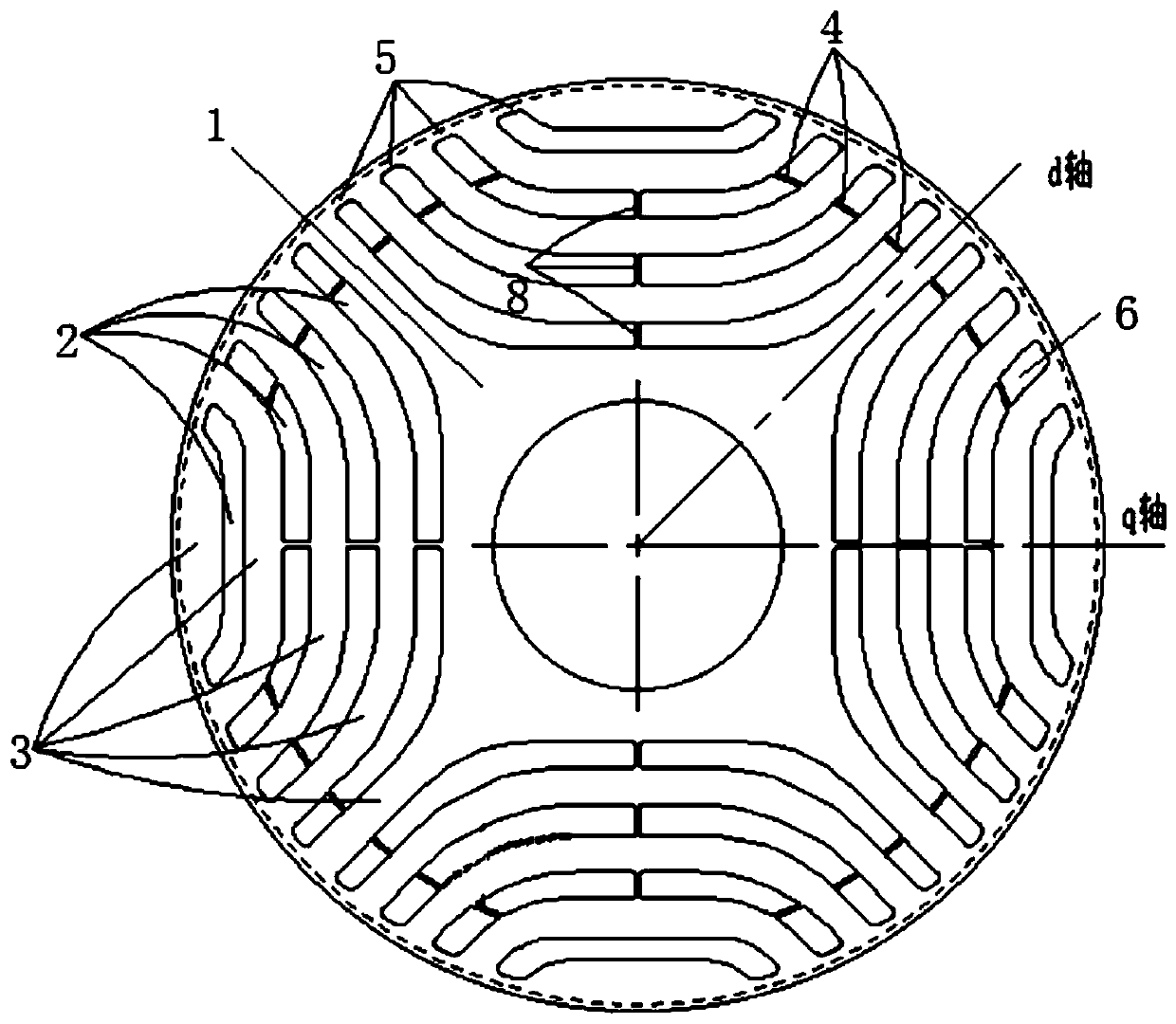

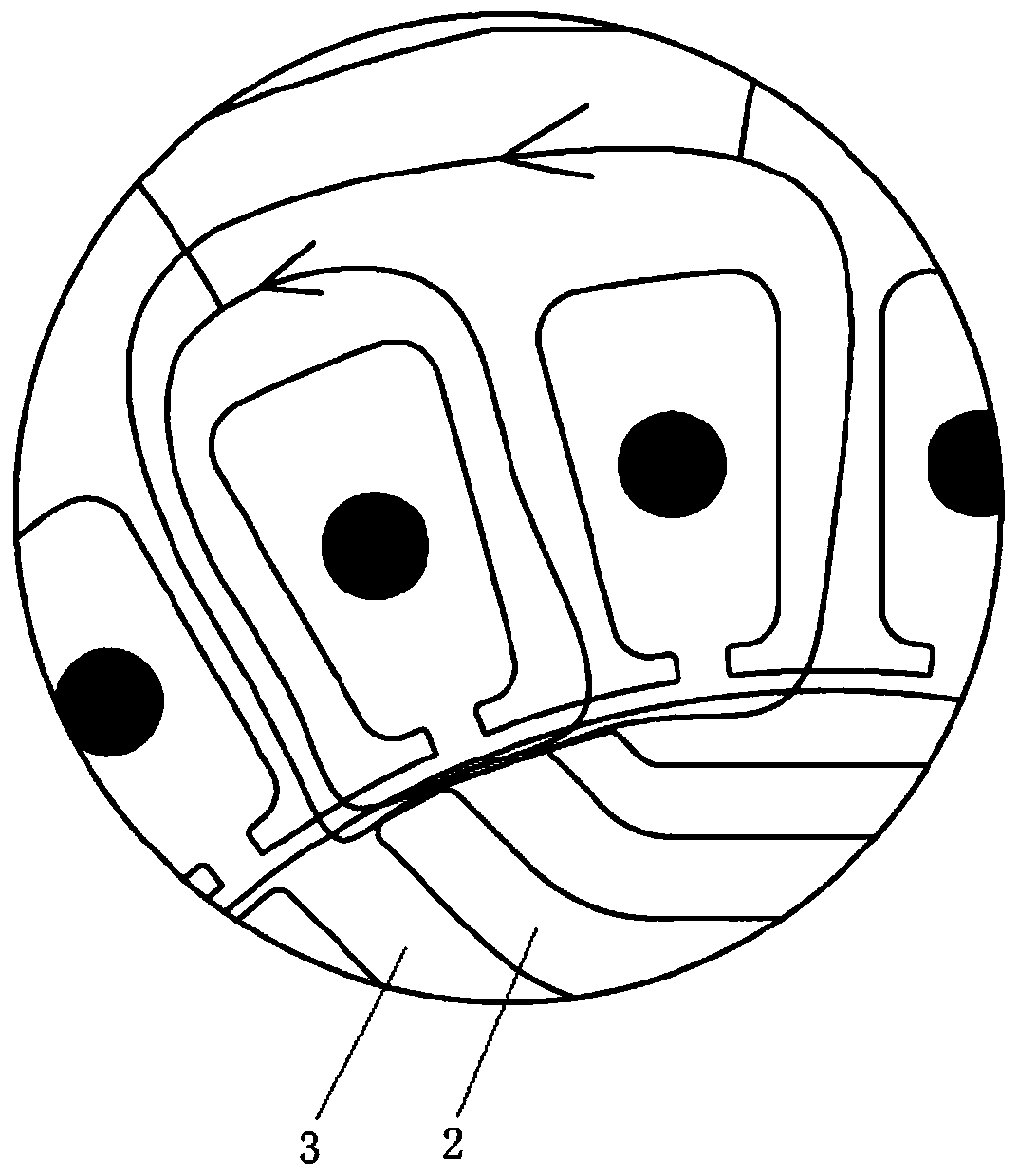

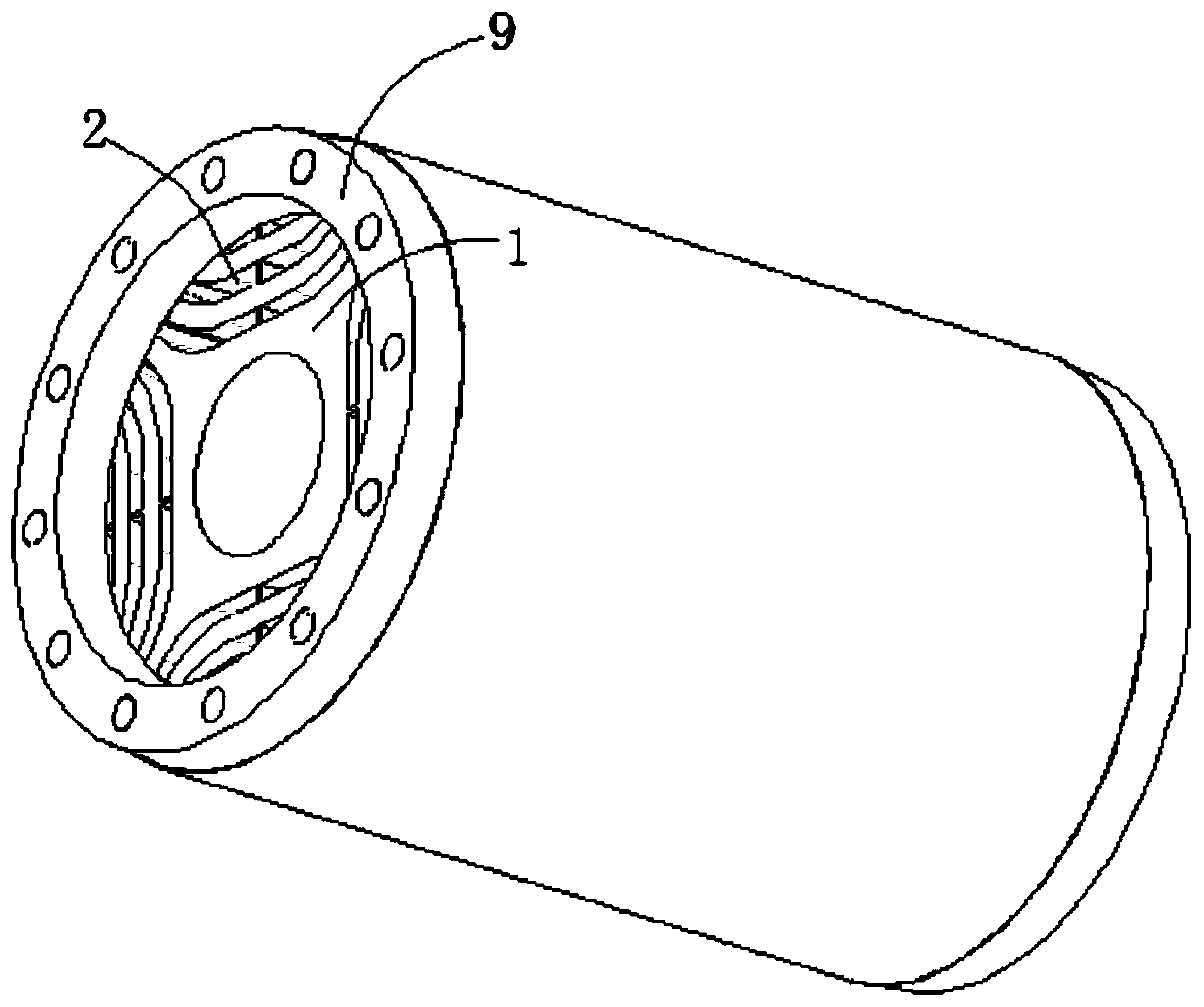

[0040] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the motor rotor includes a rotor core 1, and the rotor core 1 is provided with a plurality of magnetic barrier groups along the circumferential direction, and each magnetic barrier group includes a plurality of radially spaced magnetic fluxes. Barrier 2, magnetic conduction channels 3 are formed between adjacent magnetic flux barriers 2, each magnetic flux barrier 2 under the same pole is provided with a middle reinforcing rib 4, and the middle reinforcing rib 4 is arranged at both ends of the magnetic flux barrier 2, each magnetic flux barrier 2 The outer circumference of the rotor core 1 corresponding to the two ends of the barrier 2 is respectively provided with outer circular reinforcing ribs 5, the middle reinforcing rib 4 and the outer circular reinforcing rib 5 are arranged at intervals, the middle reinforcing rib 4, the outer circular reinforcing rib 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com