Method for efficiently reducing and removing pollutants based on boronized zero-valent iron

A zero-valent iron, boric acid technology, applied in the field of environmental chemistry, to achieve the effect of good reduction and removal capacity, low price, and low consumption of boric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

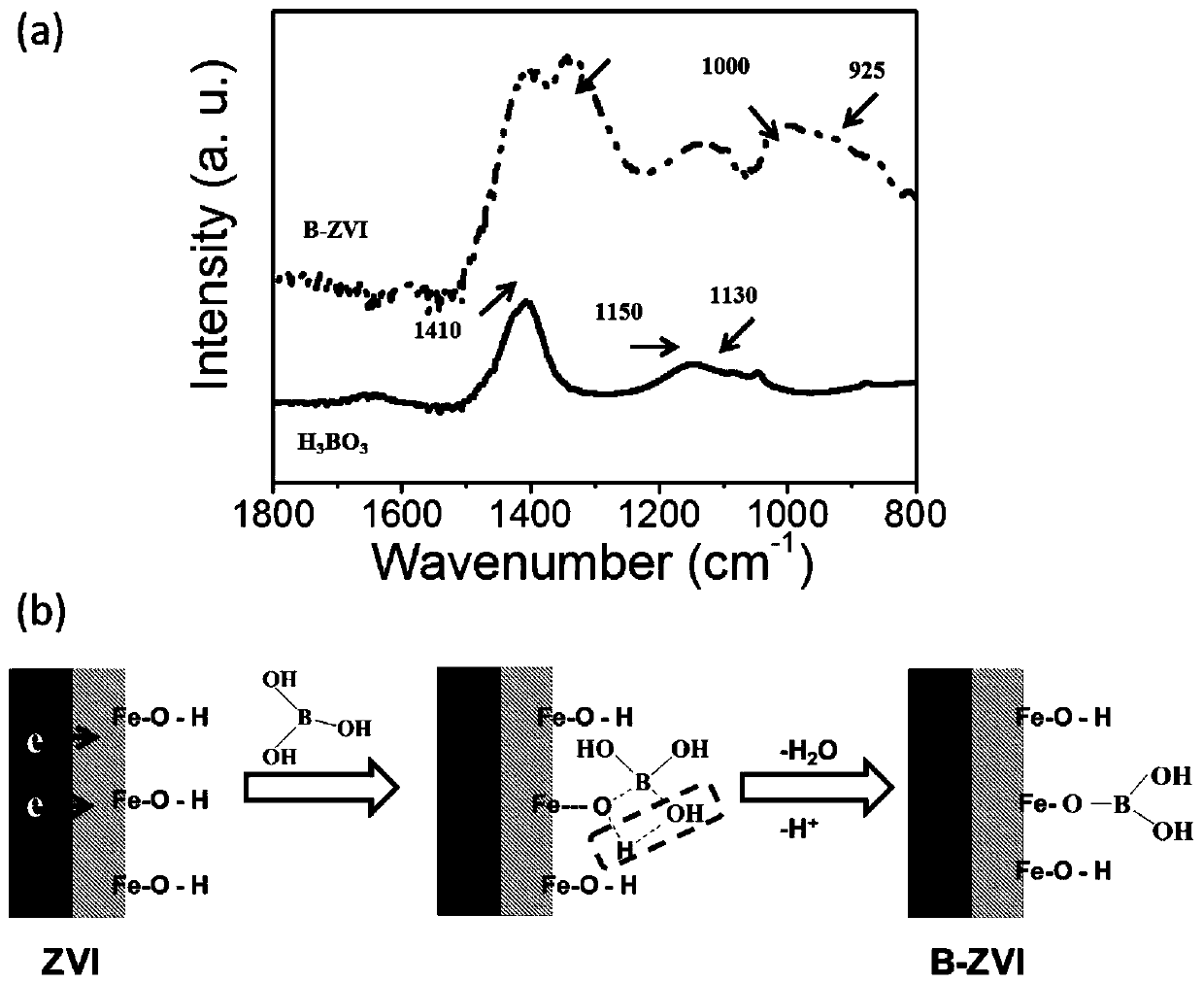

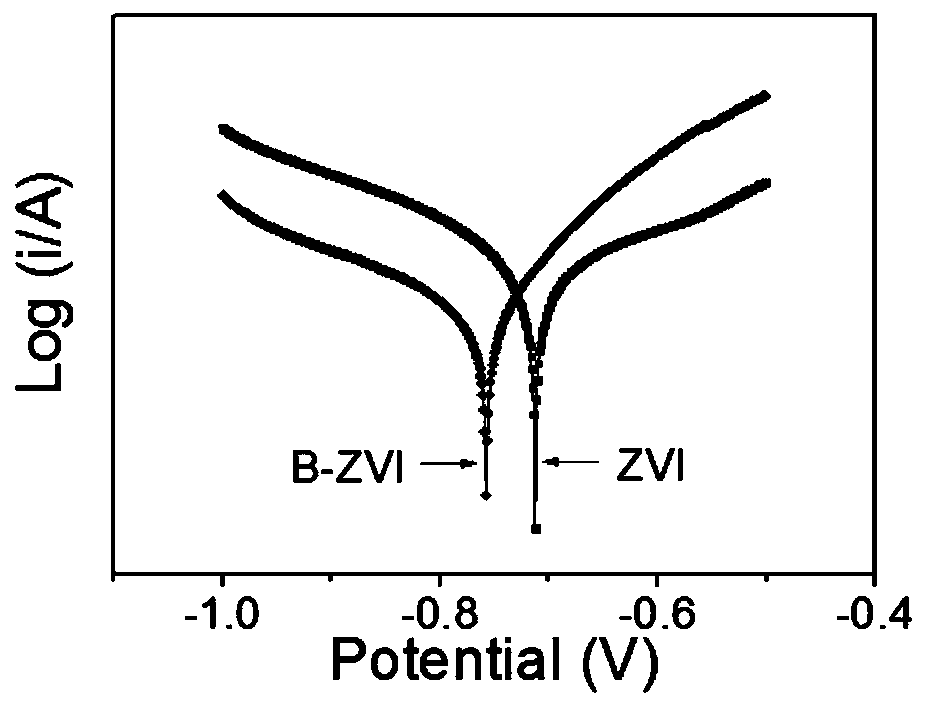

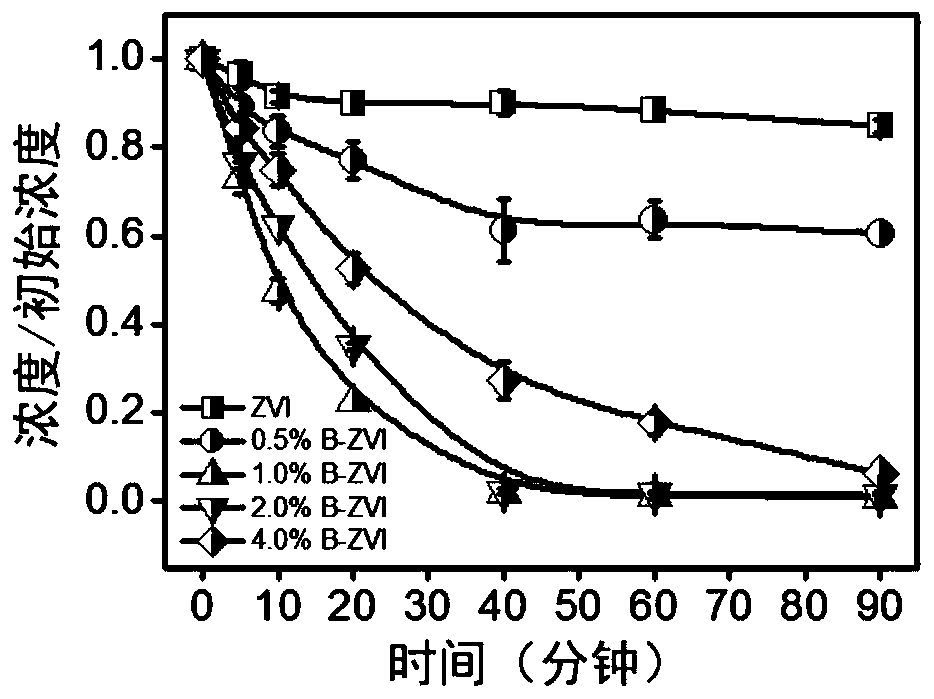

[0031] Example 1 ball milling preparation of borated zero-valent iron and effect diagram of hexavalent chromium in the treatment of polluted water;

[0032] Put 5.6g of zero-valent iron (150 μm in particle size) and a certain amount of boric acid into a ball mill jar, the rotating speed is 550r / min, and the ball milling time is 2h, after which the sample is washed with alcohol and vacuum-dried to obtain borated zero-valent iron x%B- ZVI (x% is the molar ratio of boric acid to zero-valent iron). Use 30mL of hexavalent chromium solution with a concentration of 2mg / L to simulate chromium wastewater, the pH of the solution is 7, and the temperature is 25°C, add 0.1g of B-ZVI sample, put it in a shaker with a rotation speed of 100r / min, and regularly test the hexavalent chromium in the solution. Chromium concentration, see results image 3 . The ability of borated zero-valent iron to remove hexavalent chromium is stronger than that of non-borated zero-valent iron, and the removal...

Embodiment 2

[0033] Embodiment 2 Ball milling prepares borated zero-valent iron and controls nickel effect diagram in polluted water;

[0034] Put 5.6g (particle size: 80μm) of zero-valent iron and 0.250g of boric acid into a ball mill jar at a speed of 200r / min and a ball milling time of 10h to obtain borated zero-valent iron 4.0% B-ZVI. Simulate nickel wastewater with a nickel concentration of 10mg / L and a volume of 100mL. The pH of the solution is 4 and the temperature is 50°C. Add 0.5g of B-ZVI sample, put it in a shaker with a rotation speed of 200r / min, and measure the nickel in the solution by spectrophotometry. concentration, the result is as Figure 4 . The non-borated zero-valent iron only removed 60% within 90 minutes, while the borated zero-valent iron almost removed nickel within 40 minutes, so the borated zero-valent iron can improve the removal of nickel.

Embodiment 3

[0035] Example 3 ball milling preparation of borated zero-valent iron and control effect diagram of lead in polluted water;

[0036] Put 5.6g (particle size: 150μm) of zero-valent iron and 0.5g of boric acid (the molar ratio of boric acid to zero-valent iron is 8.0%) into the ball mill jar, the rotating speed is 800r / min, and the ball milling time is 4h to obtain borated zero Valence Iron 8.0% B-ZVI. Concentration is 5mg / L volume is 50mL lead waste water, solution pH is 10, temperature is 10 ℃, add B-ZVI sample 0.2g, put into the shaker that rotating speed is 250r / min, the lead concentration in the solution is measured by atomic adsorption method, the result Such as Figure 5 . Non-borated zero-valent iron only removed 20% of lead within 90 minutes, while borated zero-valent iron removed lead within 30 minutes, so borated zero-valent iron can improve the removal of lead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com