Slow-release carbon source filler for enhancing denitrification nitrogen removal and preparation method thereof

A slow-release carbon source and denitrification technology, applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc., can solve the problem of excessive COD in effluent, difficult control of dosage, low utilization rate, etc. problem, to achieve the effect of promoting total nitrogen removal, enhancing total nitrogen removal efficiency, and long carbon release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

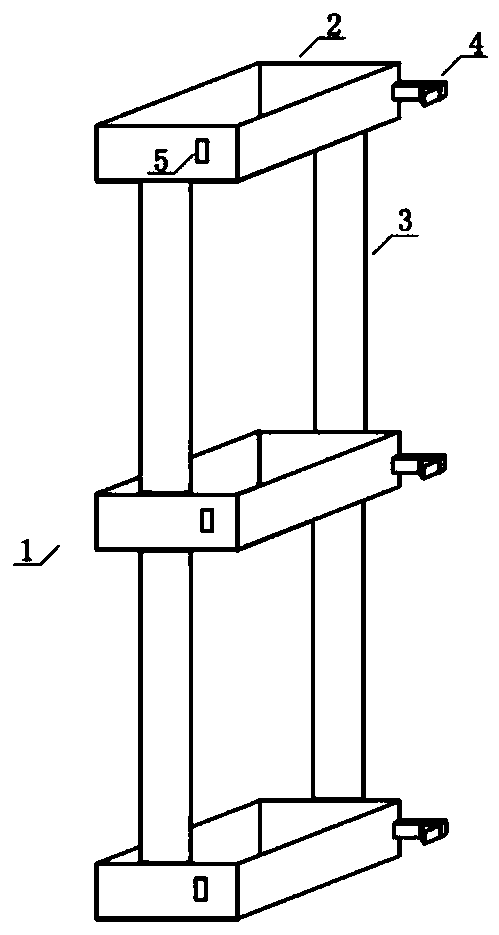

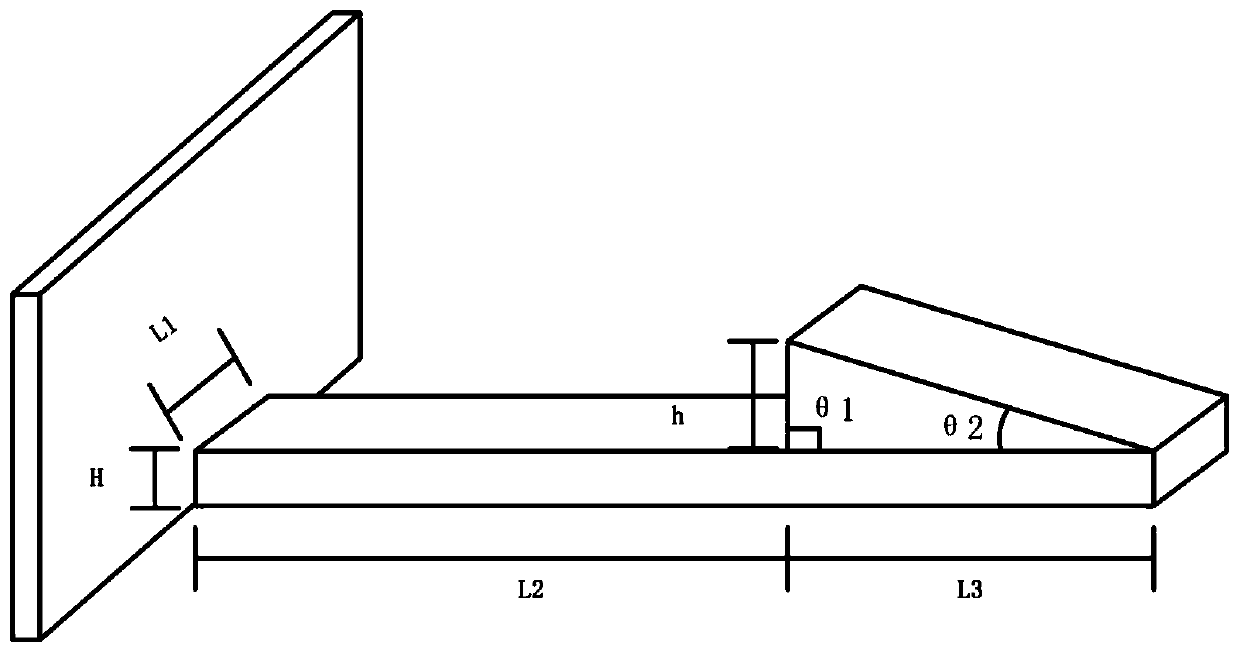

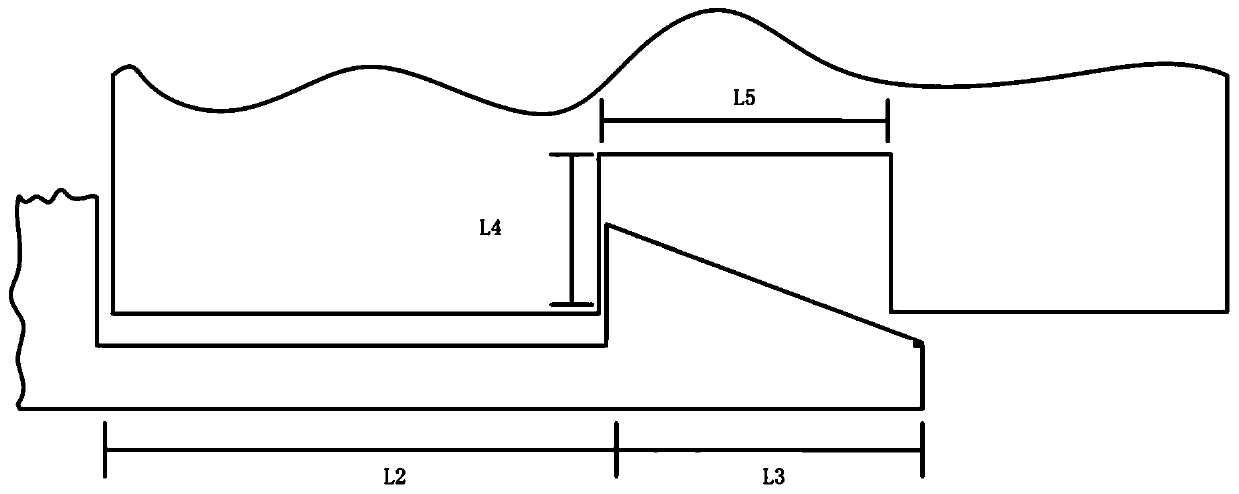

[0030] refer to Figure 1 to Figure 5, a slow-release carbon source filler for strengthening denitrification and denitrification, the slow-release carbon source filler includes a surface filler 6, an interlayer carbon source 7 and a filler shell 1, and the surface filler includes a filler base and a biodegradable carbon source, The biodegradable carbon source is covered on the filler base; the interlayer carbon source is a slow-release biodegradable carbon source; the filler shell is a plastic member that can be interconnected and combined with buckles; the surface filler is packed into the In the packing shell described above, an interlayer carbon source is placed on the surface packing, the two packing shells are spliced and fixed, and the interlayer carbon source is sandwiched between the two surface packings through the packing shell.

[0031] Further, the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com