Dicyclohexylamine modified ion exchange resin, and preparation method and application of ion exchange resin

A technology of ion exchange resin and dicyclohexylamine, which is applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of decreased adsorption performance and application limitations of aromatic sulfonic acid, Achieve the effect of low cost, simple preparation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

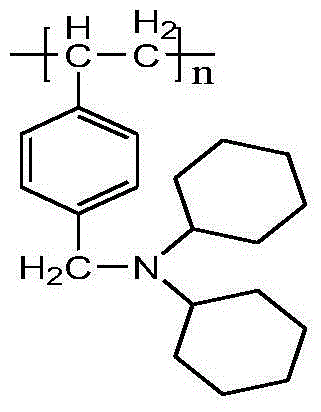

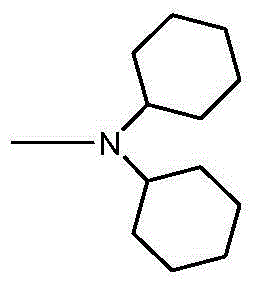

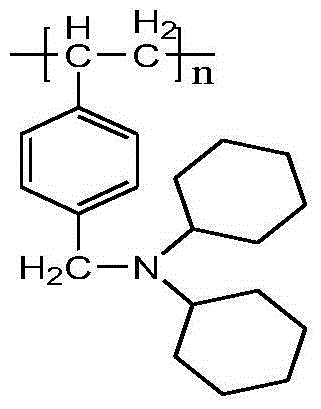

[0022] A preparation method of a dicyclohexylamine-modified ion-exchange resin. Firstly, a suspension polymerization method is used to prepare a macroporous styrene-divinylbenzene copolymer with a crosslinking degree of 4 to 12%, that is, a resin white ball, and then undergo chloromethylation. React to obtain resin chlorine balls, swell the resin chlorine balls in N,N-dimethylformamide, add dicyclohexylamine dropwise at room temperature, raise the temperature to 50-80°C, stir and react to obtain dicyclohexylamine Modified ion exchange resins. The amount of dicyclohexylamine reagent added is 2 to 8 times the mass of resin chlorine balls, and the reaction time is 4 to 12 hours. By controlling the chlorine content of resin chlorine balls, the amount of dicyclohexylamine reagent and the reaction time, a series of dicyclohexylamine reagents can be prepared. Hexylamine modified ion exchange resin.

[0023] Determine other conditions, use the resin chlorine balls of different chlori...

Embodiment 1

[0026] (a) Preparation of macroporous styrene-divinylbenzene resin white balls.

[0027] In a 250mL beaker, add 88g of styrene, 12g of divinylbenzene, and 100g of liquid paraffin, stir well and set aside. In a 1000mL three-necked flask, add 450g of distilled water and 3.75g of gelatin, raise the temperature to 40°C, add the above-mentioned mixture of styrene, divinylbenzene and liquid paraffin under stirring, add 1g of benzoyl peroxide, and add 1g of benzoyl peroxide at a rate of 0.5°C / min Raise the temperature to 75°C at a high speed, keep it warm for 5 hours, slowly raise the temperature to 85°C, keep it warm for 4 hours, after the reaction is over, filter out the resin sphere, wash it with hot water, drain it, put it into a Soxhlet extractor, use ethanol as the solvent to extract it, and then Dry with hot air to obtain macroporous styrene-divinyl styrene resin white balls.

[0028] (b) Chloromethylation reaction

[0029] In a 500mL three-neck flask, add 50g of macroporous...

Embodiment 2

[0033] The synthetic steps of another embodiment of the present invention are as follows:

[0034] (a) In a 250mL beaker, add 96g of styrene, 4g of divinylbenzene, and 50g of liquid paraffin, stir well and set aside. In a 1000mL three-necked flask, add 450g of distilled water and 3.75g of gelatin, raise the temperature to 45°C, add the above-mentioned mixture of styrene, divinylbenzene and liquid paraffin under stirring, add 1g of benzoyl peroxide, and add 1g of benzoyl peroxide at a rate of 0.5°C / min The temperature was raised to 78°C at a high speed, kept for 5 hours, slowly raised to 85°C, kept for 4 hours, the reaction was completed, the resin spheres were filtered out, washed with hot water, drained, put into a Soxhlet extractor, and extracted with acetone as a solvent, and then Dry with hot air to obtain macroporous styrene-divinyl styrene resin white balls.

[0035] (b) In a 500mL three-necked flask, add 30g of macroporous styrene-divinylbenzene resin white balls, 240g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com