Plunger assembly, lubricating pump, plunger and plunger machining method

A processing method and technology for lubricating pumps, applied in the direction of lubricating pumps, engine lubrication, pumps, etc., can solve the problems of low plunger precision and low processing efficiency, and achieve the effects of improving processing accuracy, high processing efficiency, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

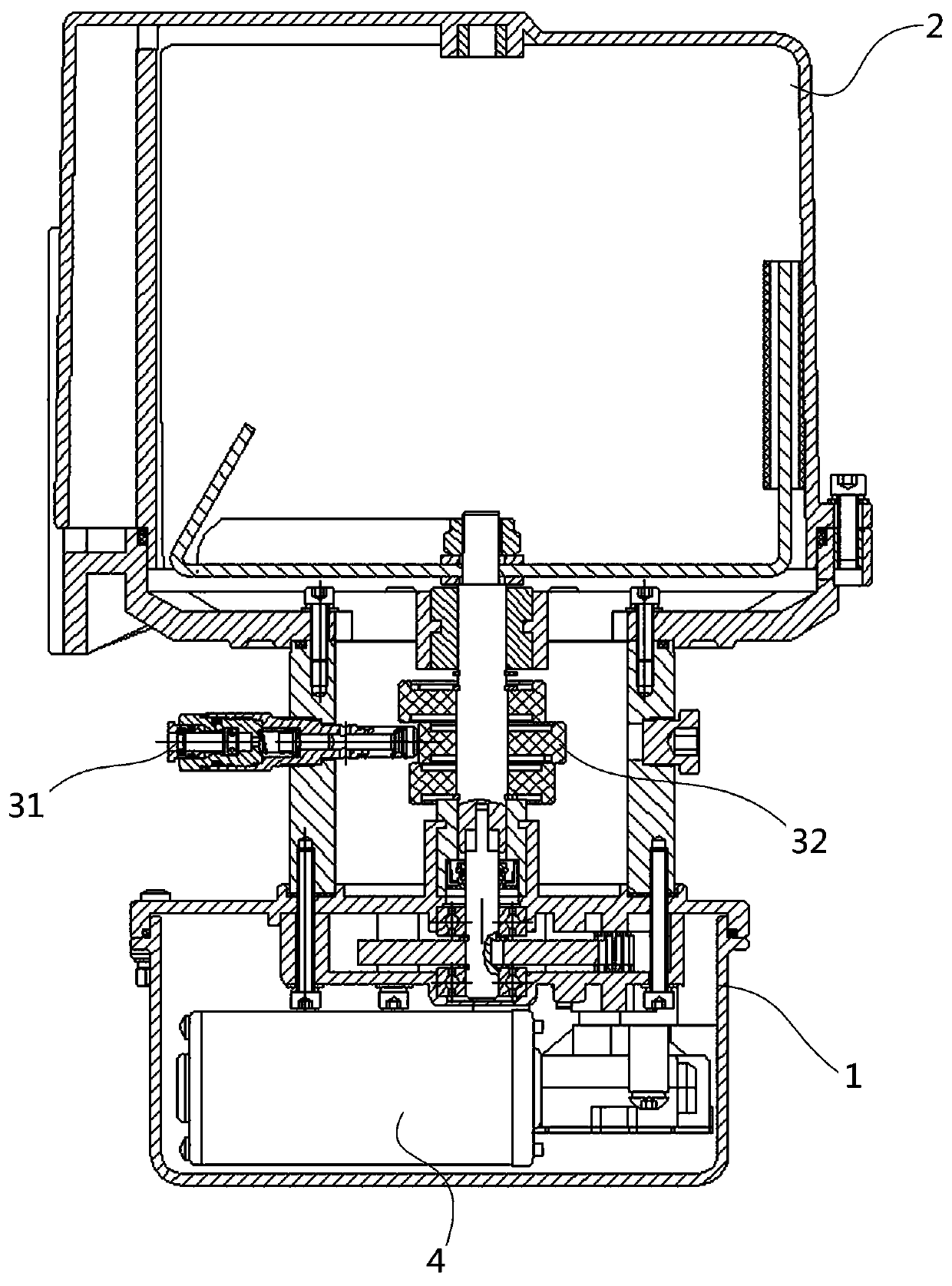

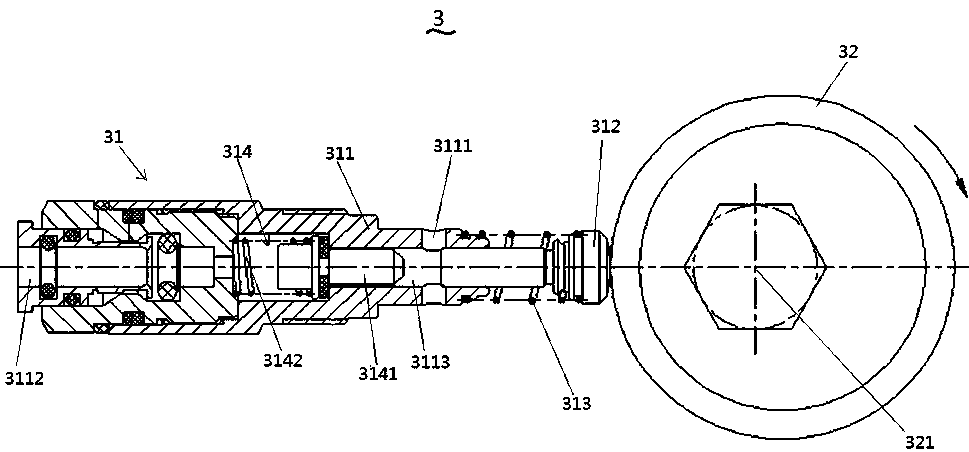

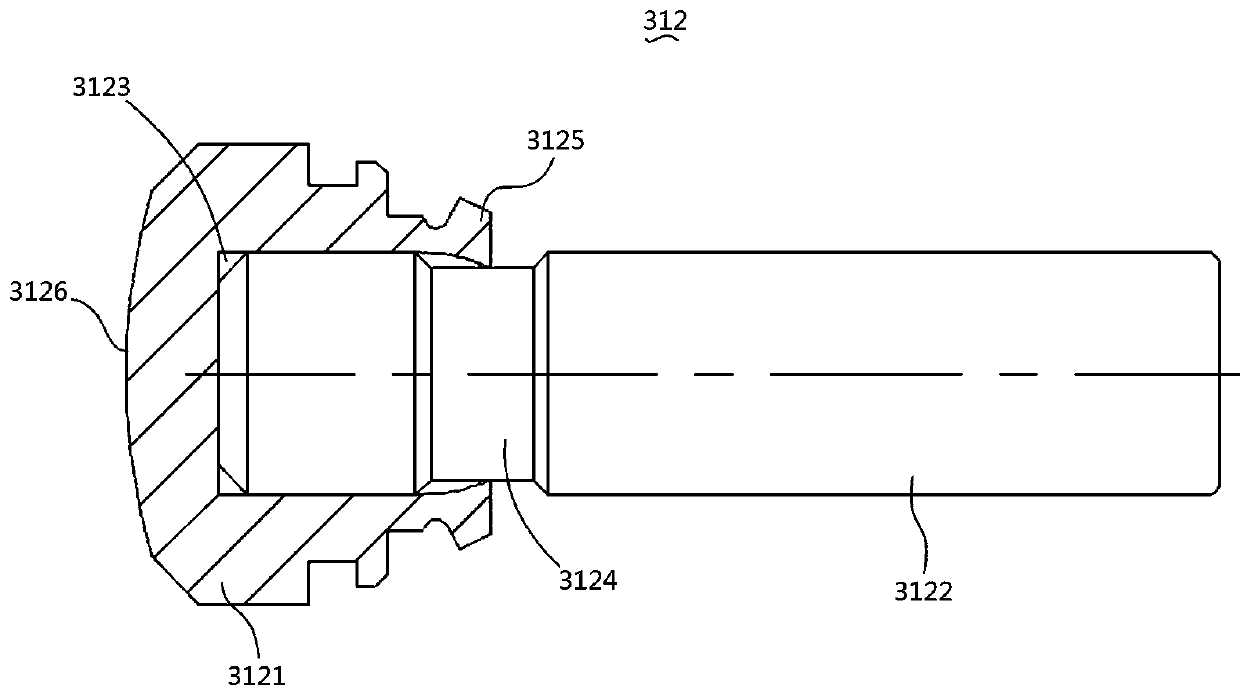

[0030] A specific embodiment of a lubricating pump of the present invention, such as Figure 1-Figure 3 As shown, it includes a pump head assembly and an oil tank 2 connected to each other. The pump head assembly includes a lubricating pump housing 1 and a plunger pair 3 installed on the lubricating pump housing 1. The plunger pair 3 includes a cam 32 and a plunger assembly 31 , the motor 4 as the driving device of the cam 32 is installed in the lubricating pump housing 1, and the transmission assembly between the motor 4 shaft and the cam 32. In the present embodiment, the motor 4 drives the rotating shaft to rotate, and three cams 32 are installed on the rotating shaft. There are multiple plunger assemblies 31 on the lubricating pump housing 1, and the specific number is determined according to the needs of use. The plunger assembly 31 includes a plunger housing 311, and the plunger housing 311 has an oil passage 3113 inside, and the oil passage 3113 has an oil suction port. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com