Pressure control method and device

A pressure control and pressure technology, applied in the field of pressure control methods and devices, can solve problems such as affecting the quality of nitrogen products, pressure fluctuations in the upper tower of an air separation plant, and reducing nitrogen purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

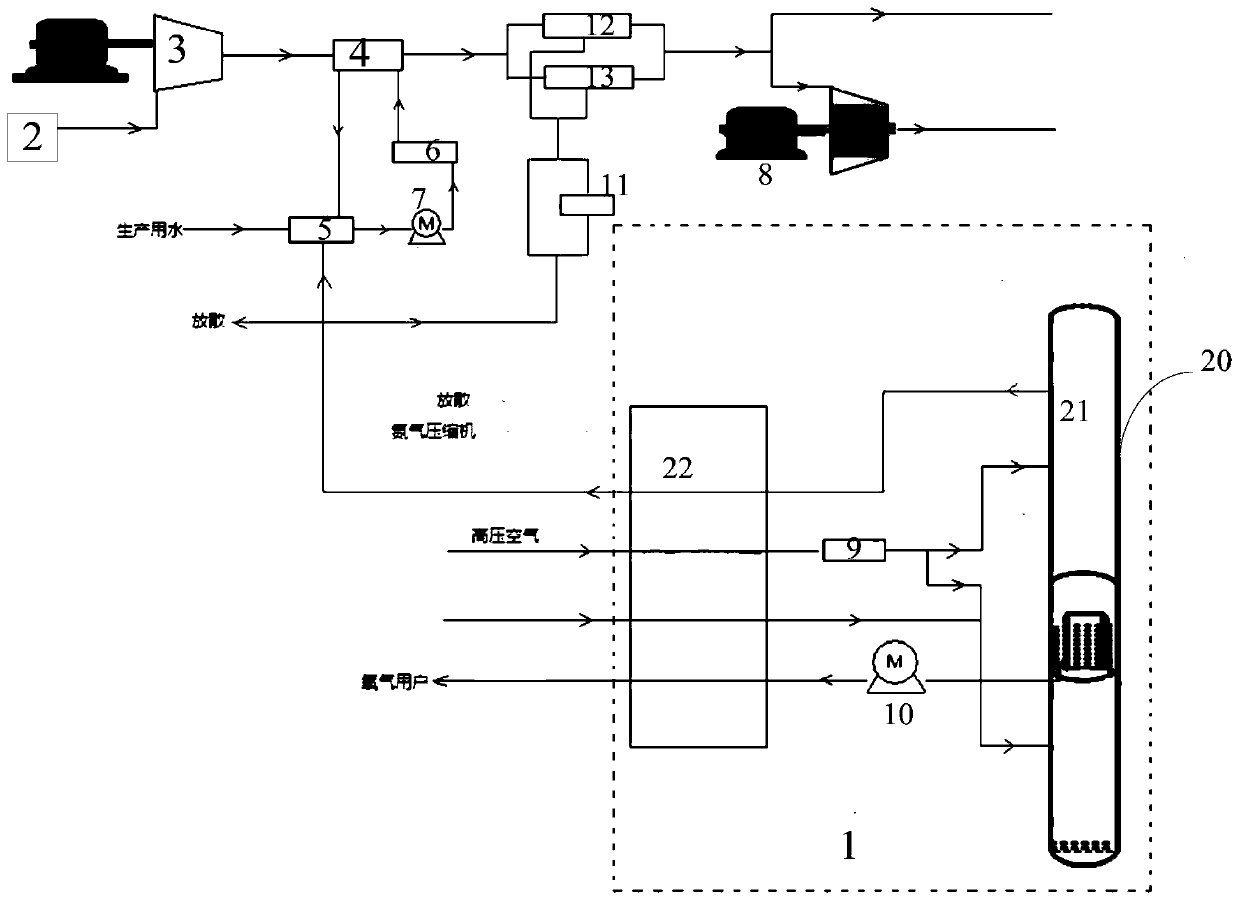

[0041] This embodiment provides a pressure control method, which is applied in the air separation system. In order to better understand the technical solution in this paper, the overall structure of the air separation system will be introduced first. see figure 1 , the air separation system includes: cold box 1, air filter room 2, air compressor 3, air cooling tower 4, nitrogen water tower 5, refrigerator 6, water pump 7, supercharger 8, expander 9, liquid oxygen pump 10, heating Device 11, molecular sieve.

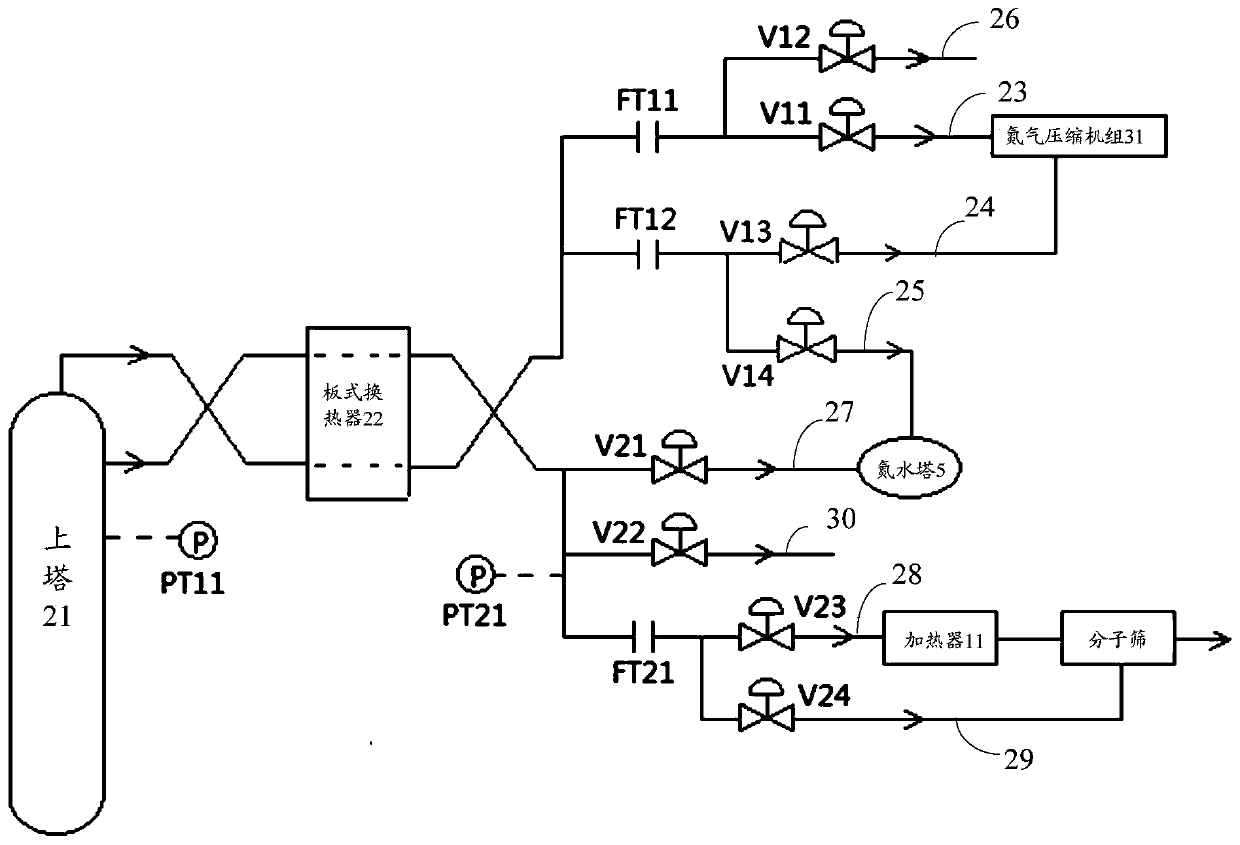

[0042] see figure 2 , an air separation tower 20 and a plate heat exchanger 22 are installed in the cold box 1. The air separation tower 20 includes an upper tower 21 and a lower tower, and the pure nitrogen pipeline and the dirty nitrogen pipeline are separated from the upper tower 21, and the pure nitrogen pipeline comes out It is finished nitrogen, which is used to provide nitrogen for enterprises. The pure nitrogen pipeline includes: the first pure nitrogen pipeli...

Embodiment 2

[0077] This embodiment provides a pressure control device, which is applied in the air separation system mentioned in Embodiment 1, such as Figure 4 As shown, the device includes: a first control unit 41, a second control unit 42, a third control unit 43, a fourth control unit 44, a fifth control unit 45, a sixth control unit 46, and a seventh control unit 47; wherein,

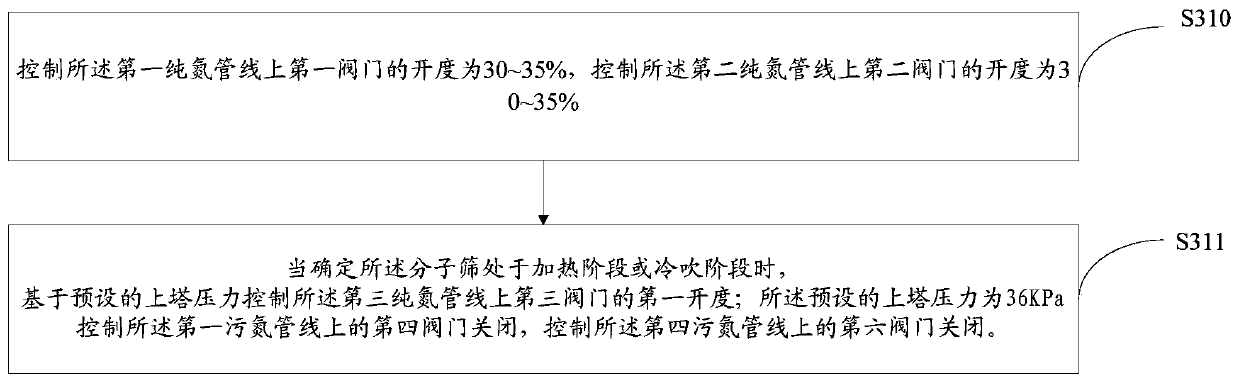

[0078]In order to ensure the nitrogen consumption of the downstream production line, regardless of whether the molecular sieve is in the heating stage or the cold blowing stage, the first control unit 41 controls the opening of the first valve on the first pure nitrogen pipeline to be 30-35%, and the second control unit 42 Control the opening of the second valve on the second pure nitrogen pipeline to 30-35%; the pure nitrogen output from the first pure nitrogen pipeline and the second pure nitrogen pipeline enters the nitrogen compressor unit, and is pressurized for use in downstream production lines. Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com