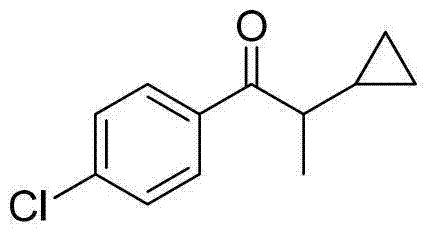

Preparation method of 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

A technology of cyclopropyl propionic acid and cyclopropyl methyl ketone, which is applied in the field of preparation of 1--2-cyclopropyl-1-propanone, can solve the problem of strict water content in the reaction system, complicated operation, chlorophenylacetonitrile Easy self-polymerization and other problems, to achieve the effect of cheap and easy-to-obtain raw materials and solvents, high yield, and reduce three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

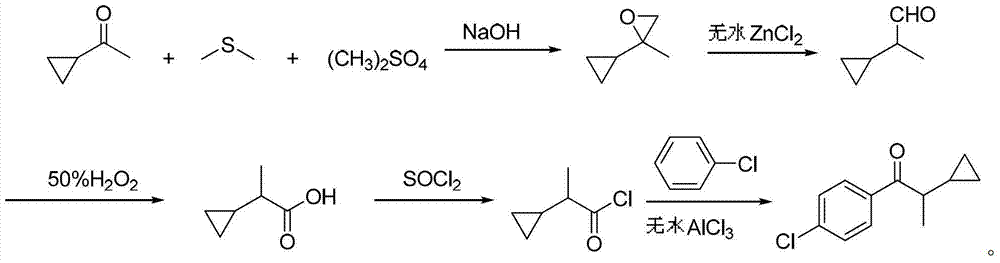

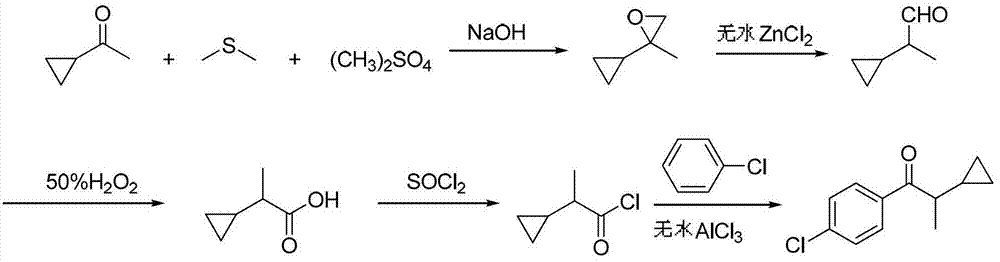

Method used

Image

Examples

Embodiment 1

[0029] Add 28.3g (0.22mol) of dimethyl sulfate, 136g of dimethyl sulfide, and 16.9g (0.20mol) of cyclopropylmethyl ketone into a 500mL three-necked flask with a stirring and reflux tube, reflux at 40°C for 1 hour, and dissolve the hydrogen Sodium oxide 17.8g (0.44mol) was added in portions within 1 hour, and the reflux reaction was continued for 2 hours. After the reaction is finished, neutralize with 10% dilute hydrochloric acid, stand to separate the phases, and reclaim dimethyl sulfide by distillation of the organic phase under normal pressure. 18.6 g of the still liquid is 2-cyclopropyl-2-methyloxirane, with a content of 96.2 % (gas chromatography), yield 93.2%.

[0030] Add 18.6g of 2-cyclopropyl-2-methyloxirane to a 100mL three-necked flask, add 0.6g of anhydrous zinc chloride at room temperature, stir for 4 hours, add 16g (0.23mol) of 50% hydrogen peroxide dropwise at room temperature , After adding in 1 hour, the reaction was continued for 3 hours, and the conversion ...

Embodiment 2

[0033] Add 28.3g (0.22mol) of dimethyl sulfate, 170g of dimethyl sulfide, and 16.9g (0.20mol) of cyclopropylmethyl ketone into a 500mL three-necked flask with a stirring and reflux tube, reflux at 40°C for 1 hour, and dissolve the hydrogen Sodium oxide 18.6g (0.46mol) was added in portions within 1 hour, and the reflux reaction was continued for 2 hours. Neutralize with 10% dilute hydrochloric acid after reaction finishes, stand to separate phases, organic phase normal pressure distillation reclaims dimethyl sulfide, still liquid 18.9g is 2-cyclopropyl-2-methyloxirane, content 96.5 % (gas chromatography), yield 95.0%.

[0034] Add 18.9g of 2-cyclopropyl-2-methyloxirane to a 100mL three-necked flask, add 0.7g of anhydrous zinc chloride at room temperature, stir for 6 hours, add dropwise 18.2g (0.26mol) of 50% Hydrogen peroxide was added in 1 hour, and the reaction was continued for 3 hours, and the conversion of 2-cyclopropylpropionaldehyde was complete as detected by liquid c...

Embodiment 3

[0037] Add 28.3g (0.22mol) of dimethyl sulfate, 170g of dimethyl sulfide, and 16.9g (0.20mol) of cyclopropylmethyl ketone into a 500mL three-necked flask with a stirring and reflux tube, reflux at 40°C for 1 hour, and dissolve the hydrogen Sodium oxide 19.4g (0.48mol) was added in portions within 1 hour, and the reflux reaction was continued for 3 hours. After the reaction is finished, neutralize with 10% dilute hydrochloric acid, stand to separate phases, and reclaim dimethyl sulfide by atmospheric distillation of the organic phase. 19.2 g of the still liquid is 2-cyclopropyl-2-methyloxirane, with a content of 96.1 % (gas chromatography), yield 94.1%.

[0038] Add 19.2g of 2-cyclopropyl-2-methyloxirane to a 100mL three-necked flask, add 0.96g of anhydrous zinc chloride at room temperature, stir for 6 hours, add dropwise 19.7g (0.28mol) of 50% Hydrogen peroxide was added in 1 hour, and the reaction was continued for 4 hours, and the conversion of 2-cyclopropylpropionaldehyde wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com