Acid-rain-resistant waterborne anticorrosive coating for steel structures and preparation method thereof

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor paint film and anti-corrosion effect, and achieve the effect of strong adhesion, low price and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

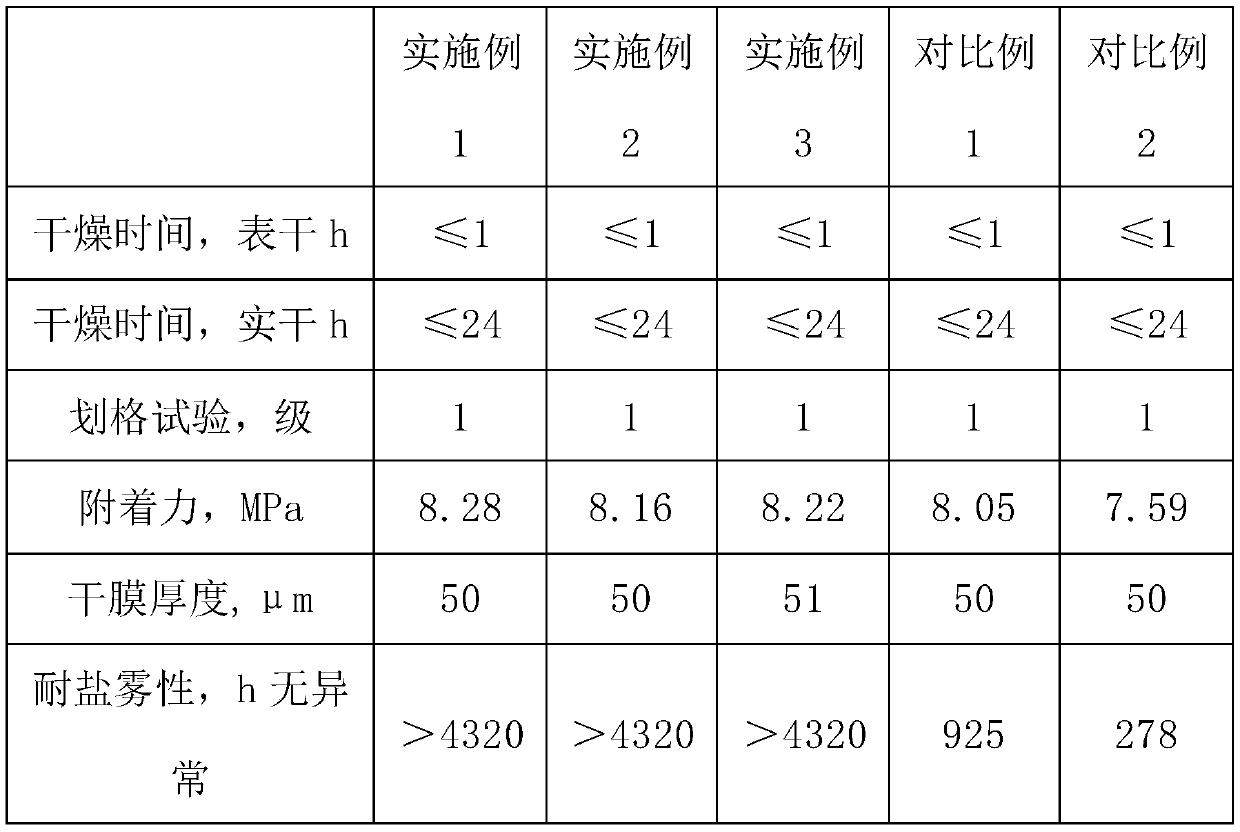

Examples

Embodiment 1

[0034] An acid rain-resistant water-based anticorrosive coating for steel structures, including the following components by weight percentage:

[0035] Acrylic emulsion 28%

[0036] pH adjuster 0.3%

[0037] Homemade slurry 26%

[0038] Film forming aid 6%

[0039] Defoamer 0.15%

[0040] Anti-flash rust additives 0.8%

[0041] Thickener 0.12%

[0042] Water margin.

[0043] The pH regulator is 2-amino-2-methyl-1-propanol; the film-forming aid is Eastman Texanol; the defoamer is Tego 1488; the anti-flash The rust additive is Deqian FA-179; the thickener is Wanhua Chemical A401.

[0044] The self-made slurry includes the following ingredients by weight percentage:

[0045] Dispersant 2.8%

[0046] Wetting agent 0.25%

[0047] pH regulator 0.22%

[0048] Masterbatch 5.5%

[0049] Marble powder 8%

[0053] Modified carbon black 1.8%.

[0054] In the self-made slurry, the dispersant is polyacrylic acid ammonium salt dispersant...

Embodiment 2

[0060] An acid rain-resistant water-based anticorrosive coating for steel structures, including the following components by weight percentage:

[0061] Acrylic emulsion 25%

[0062] pH adjuster 0.5%

[0063] Homemade slurry 30%

[0064] Film forming aid 4%

[0065] Defoamer 0.2%

[0066] Anti-flash rust additives 0.5%

[0067] Thickener 0.15%

[0068] Water margin.

[0069] The pH regulator is 2-amino-2-methyl-1-propanol; the film-forming aid is Eastman Texanol; the defoamer is Tego 1488; the anti-flash The rust additive is Deqian FA-179; the thickener is Wanhua Chemical A401.

[0070] The self-made slurry includes the following ingredients by weight percentage:

[0071] Dispersant 3%

[0072] Wetting agent 0.1%

[0073] pH adjuster 0.25%

[0074] Masterbatch 3%

[0075] Marble powder 10%

[0076] Zinc powder 8%

[0077] Mica powder 15%

[0078] Zinc phosphate 1%

[0079] Modified carbon black 2%

[0080] In the self-made slurry, the dispersant is polyacrylic acid ammonium salt dispersant; the wettin...

Embodiment 3

[0085] An acid rain-resistant water-based anticorrosive coating for steel structures, including the following components by weight percentage:

[0086] Acrylic emulsion 35%

[0087] pH adjuster 0.2%

[0088] Homemade slurry 20%

[0089] Film forming aid 8%

[0090] Defoamer 0.1%

[0091] Anti-flash rust additives 1%

[0092] Thickener 0.1%

[0093] Water margin.

[0094] The acrylic emulsion is Dow BESTWIN 0639; the pH adjusting agent is 2-amino-2-methyl-1-propanol; the film-forming aid is Eastman Texanol; the defoaming agent The agent is Tego 1488; the anti-flash rust additive is Deqian FA-179; the thickener is Wanhua Chemical A401.

[0095] The self-made slurry includes the following ingredients by weight percentage:

[0096] Dispersant 2%

[0097] Wetting agent 0.3%

[0098] pH adjuster 0.15%

[0099] Color masterbatch 8%

[0100] Marble powder 5%

[0101] Zinc powder 12%

[0102] Mica powder 10%

[0103] Zinc phosphate 3%

[0104] Modified carbon black 1%

[0105] In the self-made slurry, the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com