Light steel-steel cable-small diameter material-composite board surface layer L-shaped section combined wall and manufacturing method thereof

A technology of small-diameter materials and composite panels, which is applied to walls, building components, and climate change adaptation, can solve problems such as slow construction speed, low seismic energy consumption capacity, and poor thermal insulation performance, achieving short construction periods and high living comfort , the effect of a high level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific implementation examples.

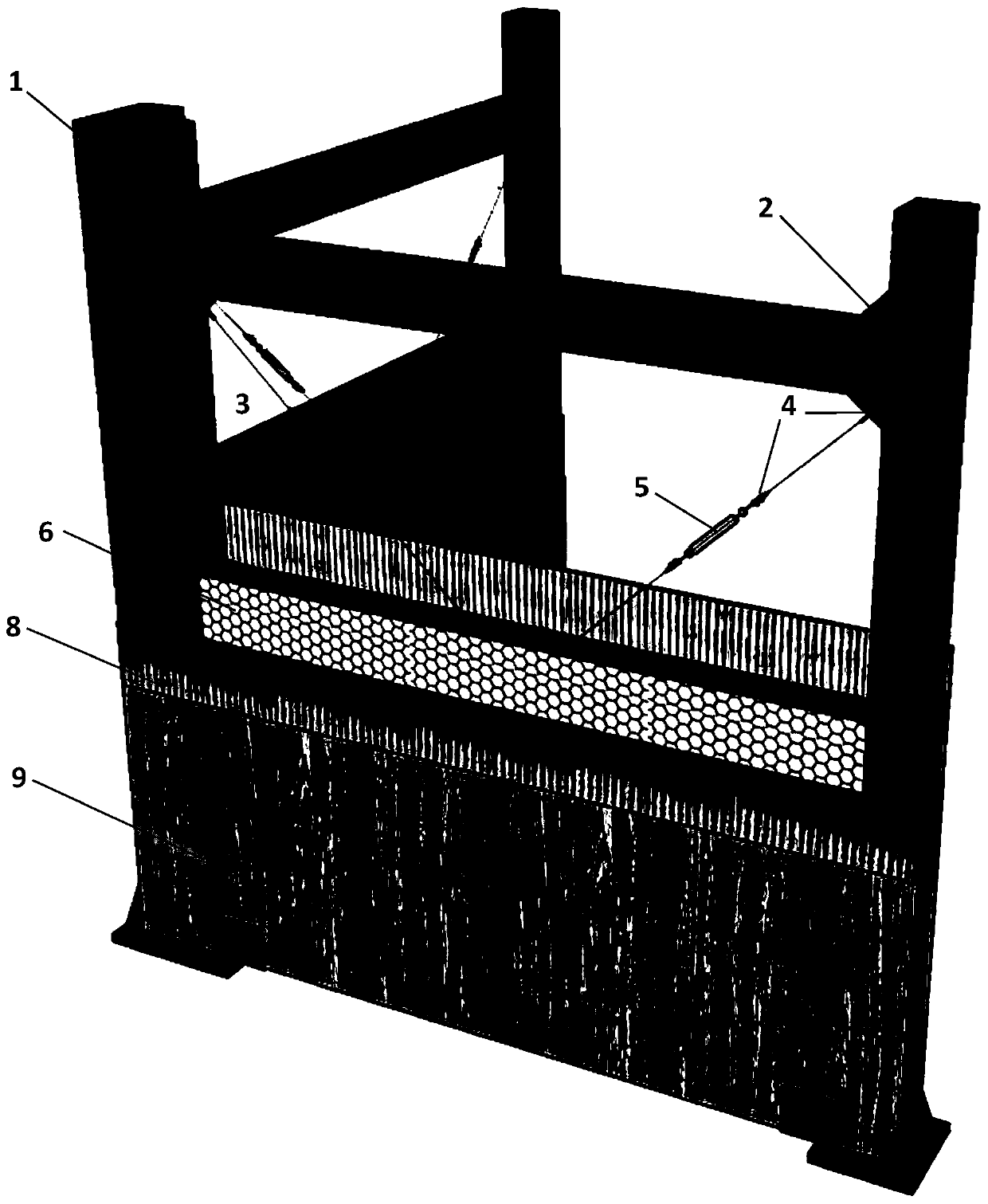

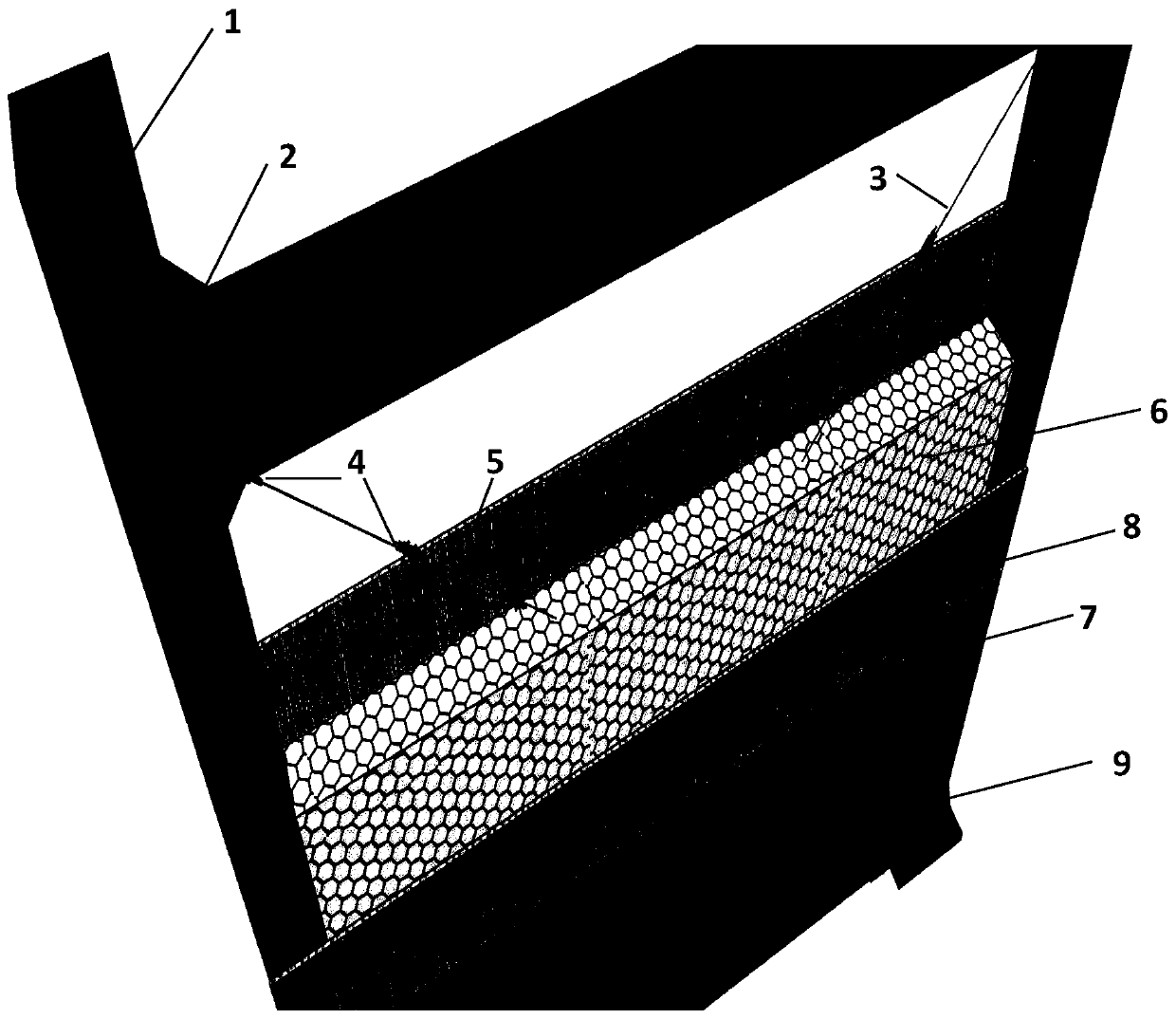

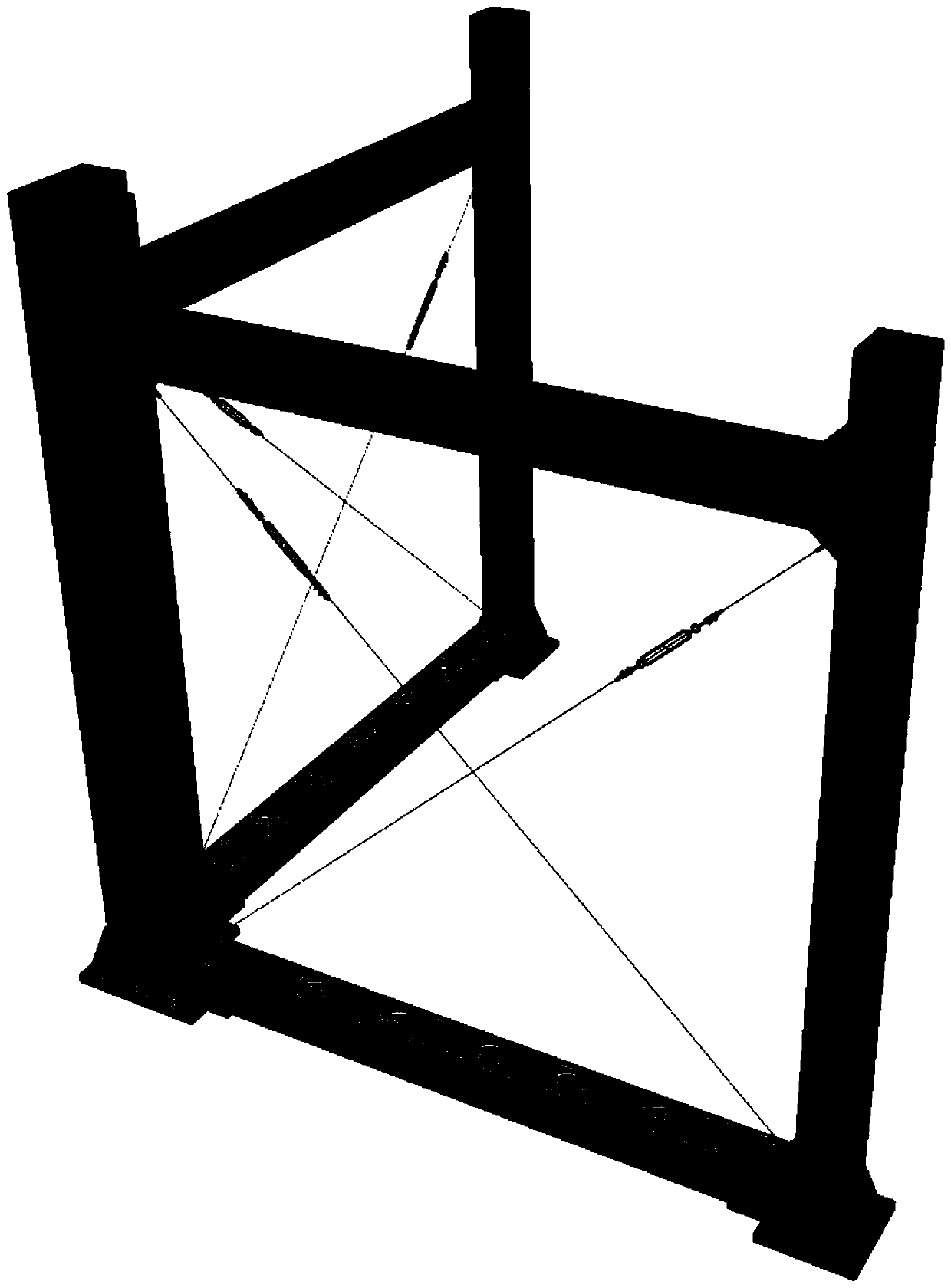

[0036] Such as Figure 1-6 As shown, the light steel frame-steel cable bracing-small-diameter material panel-composite board surface layer L-shaped section composite wall is characterized in that it includes light steel frame (1), stiffeners (2), prestressed steel cable bracing (3), fasteners (4), fastening flange rods (5), foamed polystyrene particle lightweight concrete (6), small-diameter bamboo nail spliced planks (7), self-tapping screws (8) and composite The surface plate (9); the light steel frame (1) is an L-shaped beam-column frame structure, which is arranged at the corner of the house; the light steel column of the light steel frame (1) is a vertical load-bearing member; the prestressed steel cable brace (3 ) are diagonally crossed and connected with the stiffeners (2) welded on the beam-column joints through fasteners (4), and are fastened with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com