Resonant cavity-based lateral current limiting high-efficiency light-emitting diode

A light-emitting diode and lateral current technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as Joule heat, reduced light extraction rate, and low external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

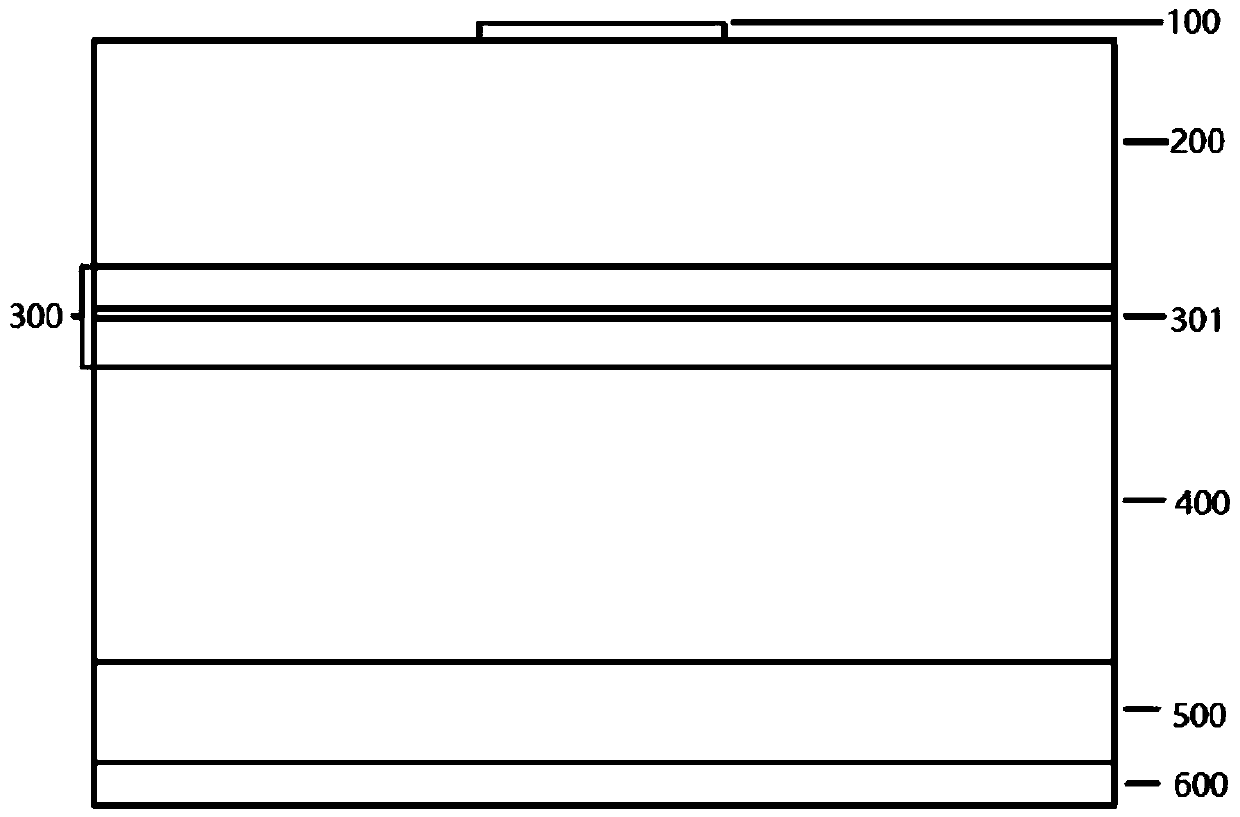

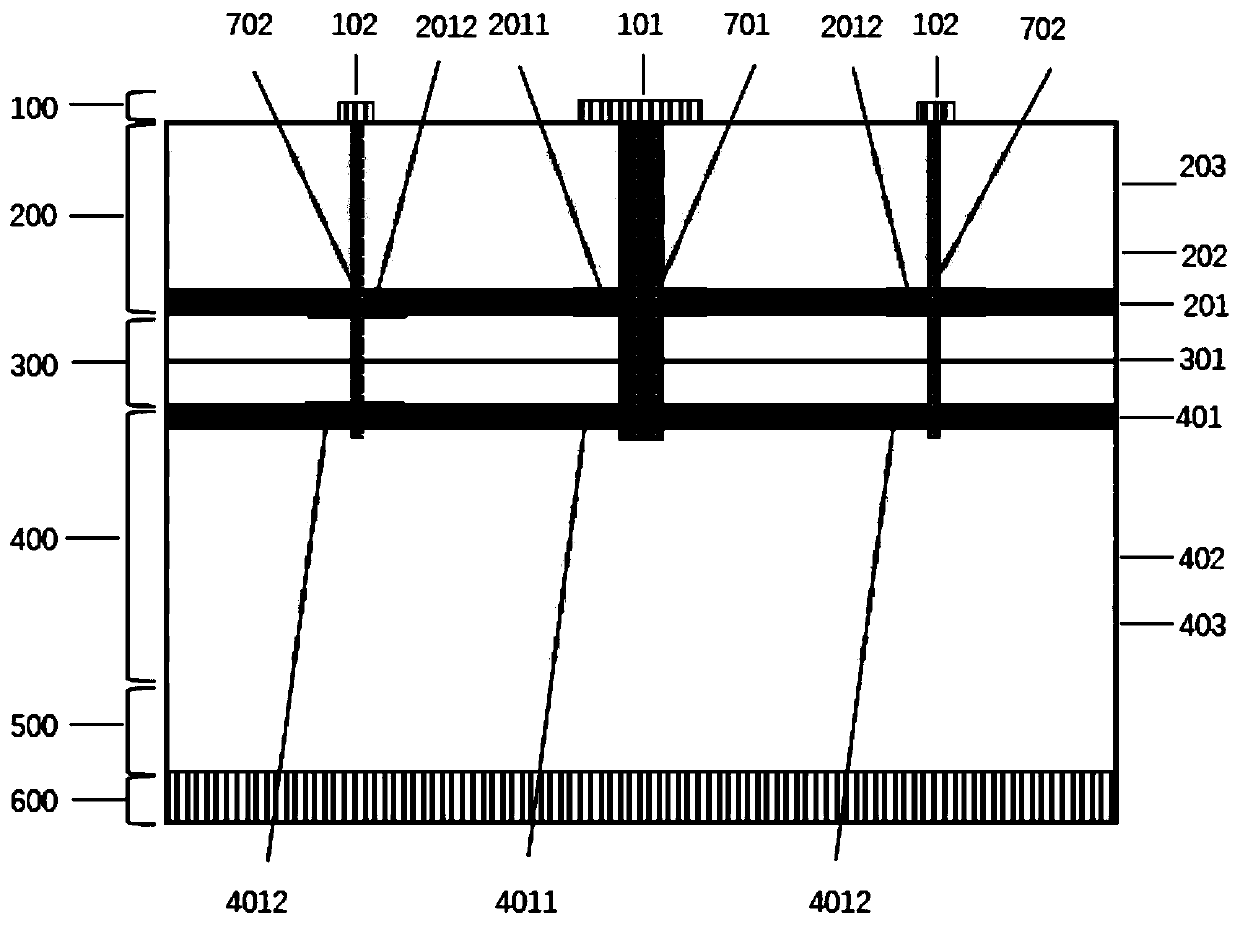

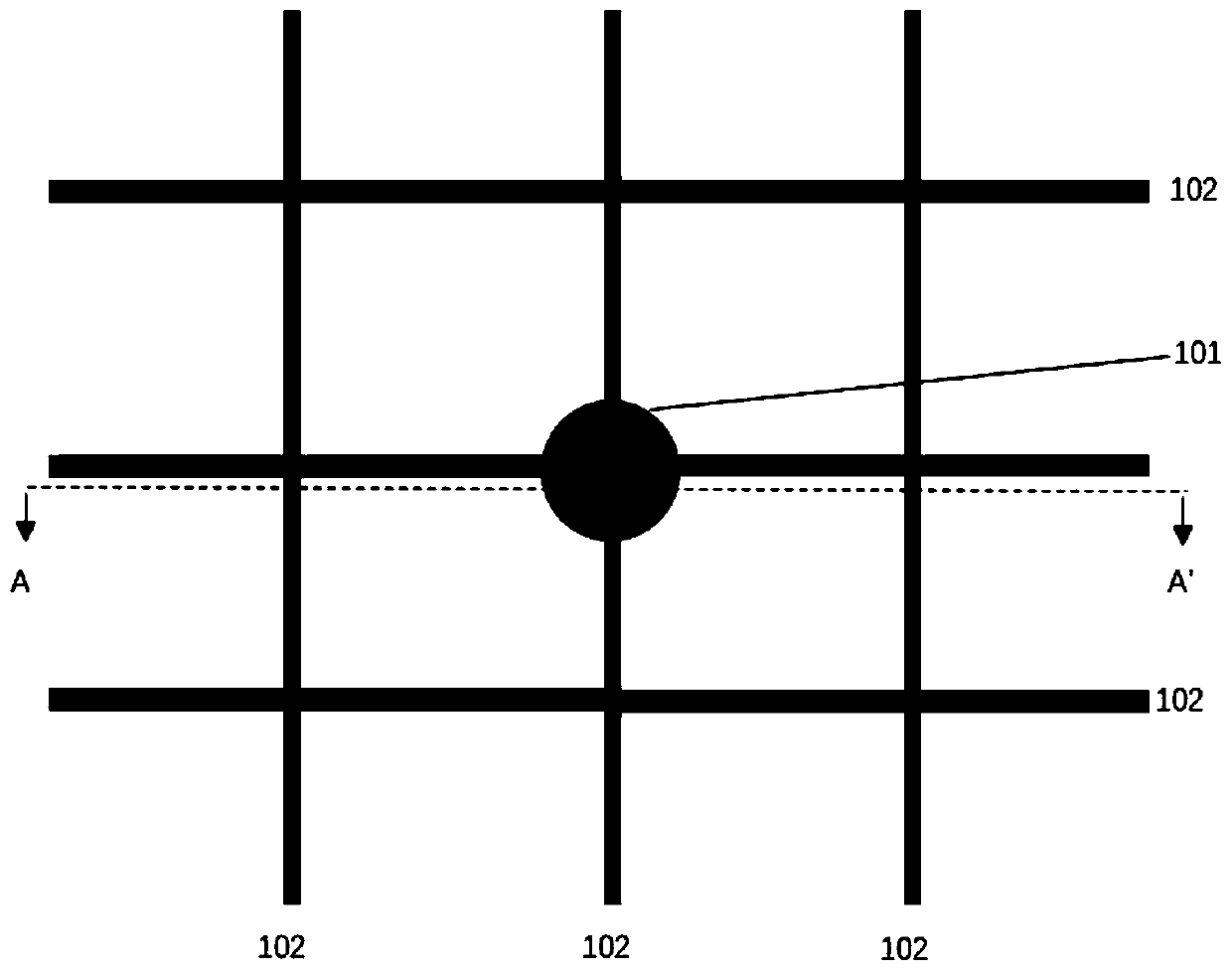

[0016] 1. A resonant cavity-based lateral current confinement high-efficiency light-emitting diode, comprising an upper electrode (100), an upper Bragg reflector (200), a resonant cavity (300), a lower Bragg reflector (400), and a substrate from top to bottom Bottom (500), lower electrode (600). The upper electrode (100) is composed of a pressure welding upper electrode (101) and a current expansion upper electrode (102); the upper Bragg reflector (Distributed Bragg Reflector Mirror, DBR) (200) is composed of a low refractive index material layer (202) and a high The refractive index material layers (203) are alternately formed, the active region (301) is located in the middle of the resonant cavity (300), and the lower Bragg reflector (400) is composed of low refractive index material layers (402) and high refractive index material layers (403) alternately constitute. The bottom layer of material layer of the upper Bragg reflector (200) is an upper DBR easily oxidizable mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com