Construction method of water island reef blowing filling construction sand filling machine

A technology of blowing and filling construction and sand filling machine, which is applied in filling, water filling and land building, infrastructure engineering and other directions, can solve problems such as the threat to the safety of life and property of the upper structure, poor particle size grading, and unstable foundation. Achieve far-reaching engineering practical significance and application prospects, avoid land subsidence, and increase the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

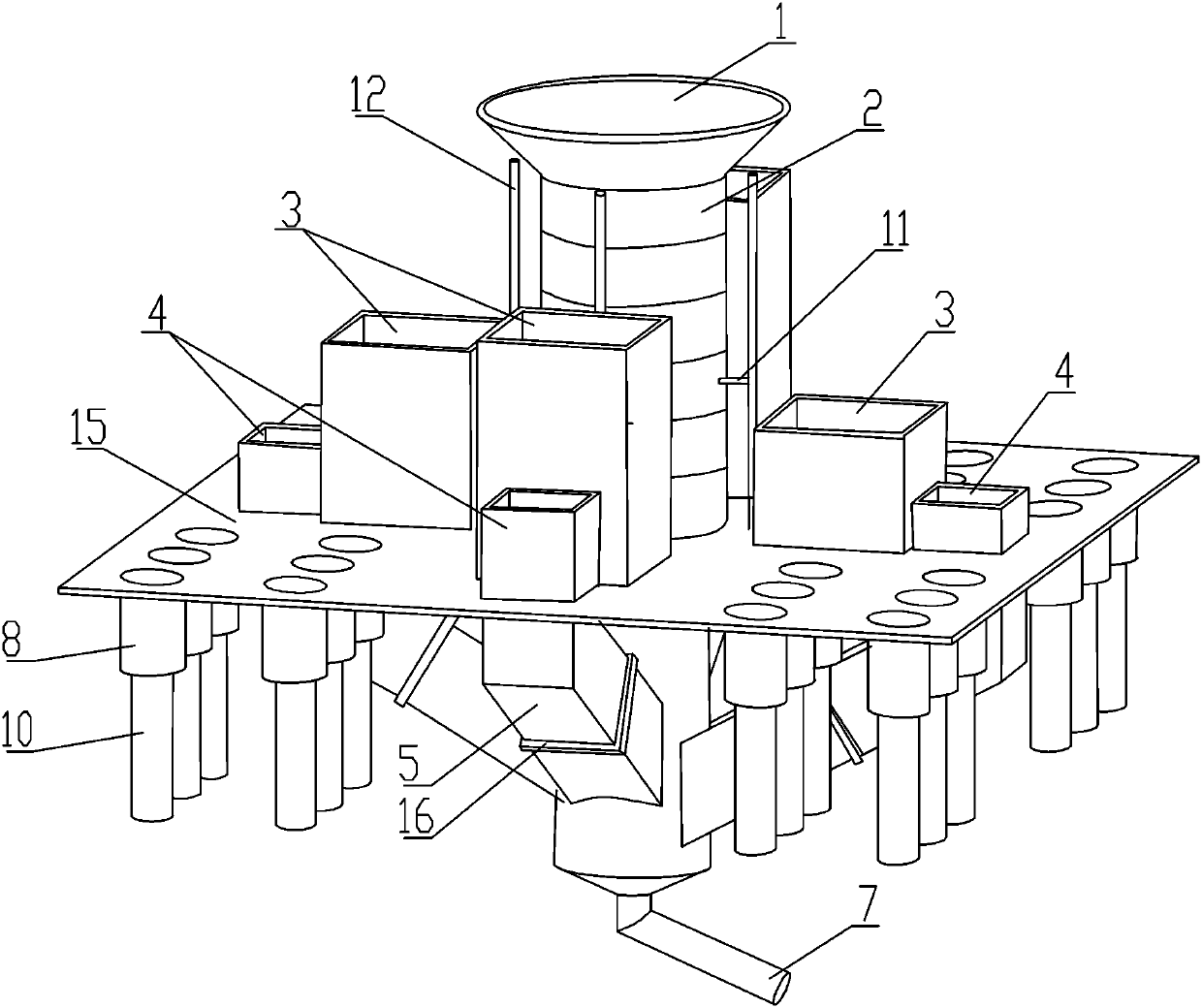

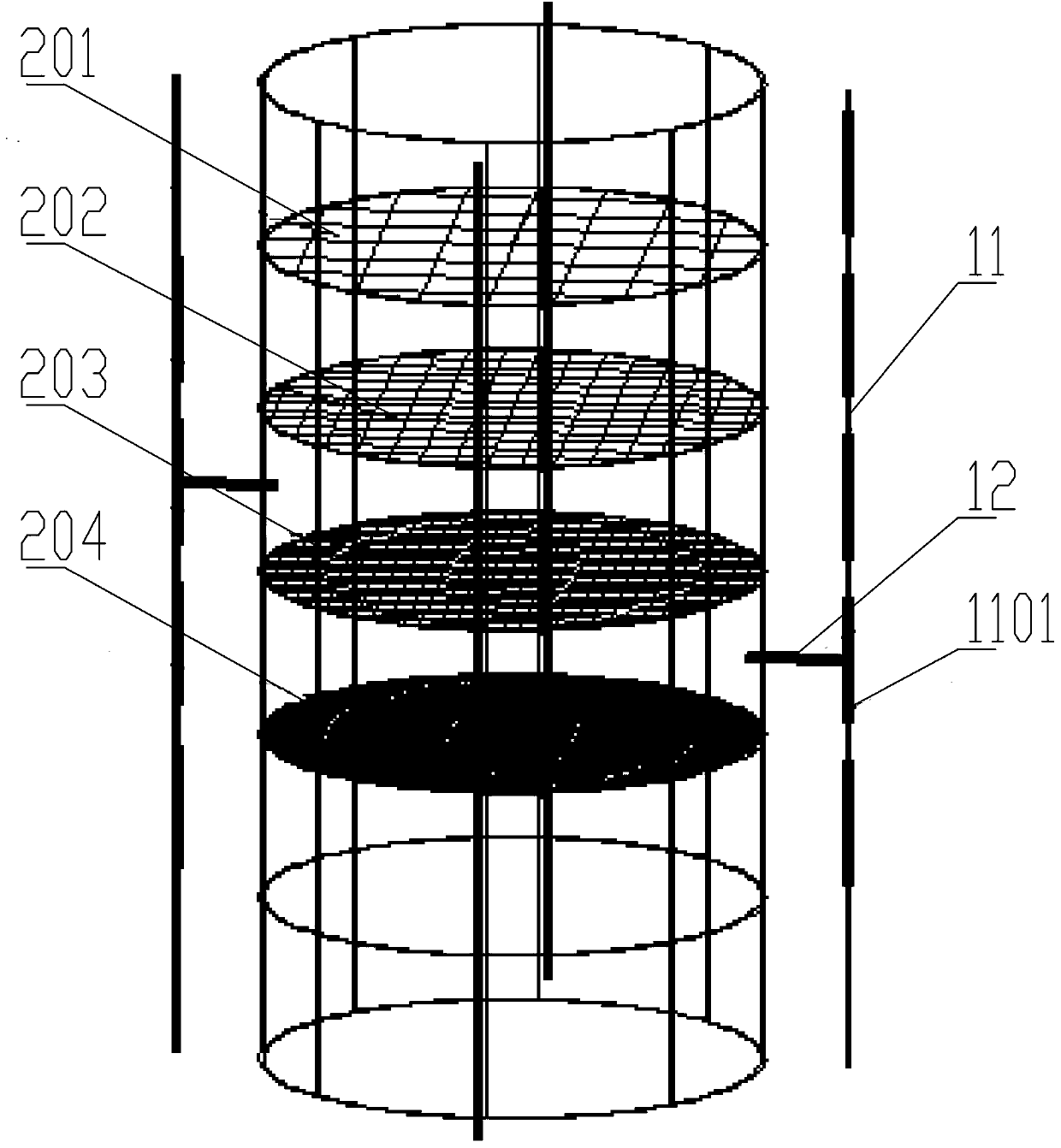

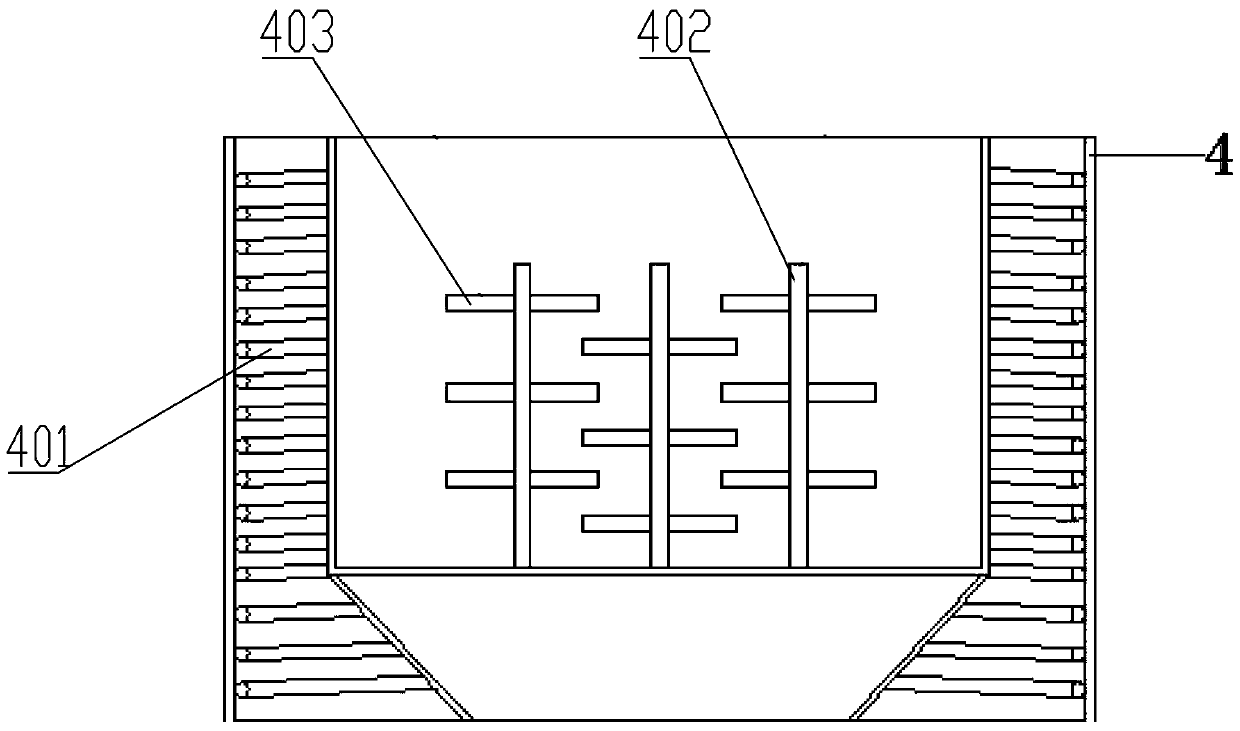

[0050] Such as Figure 1-8 , a sand-filling machine for water island and reef blow-filling construction, which includes a reef sand receiving bucket 1, and the reef sand receiving bucket 1 is installed on the top of the vibrating screen 2, and the vibrating screen 2 is installed on the top of the platform 15, and on the platform 15 And be positioned at the periphery of vibrating screen 2 and be provided with a plurality of evenly distributed water flow separation tanks 3 for separating the reef sand, the outer wall of the water flow separation tank 3 is provided with a broken stirring tank 4 for broken reef sand, the crushing and stirring Tank 4 is fixed on the top of platform 15, is connected with drying pipeline 5 by flange 16 at the bottom of crushing mixing tank 4, and the bottom of described drying pipeline 5 links to each other with mixing tank 18, and the top of described mixing tank 18 is provided with Drying box 17; the four corners of the bottom of the platform 15 ar...

Embodiment 2

[0063] The method for constructing using any one of the above-water island and reef dredging construction sand-filling machines comprises the following steps:

[0064] The first step is construction preparation: before the dredging and filling of embankment earthwork, apply for offshore and underwater construction operation permit procedures; select dredgers and construction machines, and dispatch ships and machines; purchase preliminary construction materials; At the same time, sufficient engineering and technical personnel and management personnel are transferred to ensure the construction period and quality; with the approval of the maritime department, temporary navigation aids and construction warning signs are set up to ensure the safety of construction ships and navigation;

[0065] Step 2: Carry out joint survey of the dredging and reclamation project before the dredging and reclamation: use dual-frequency RTK-GPS and digital automatic sounding system for surveying, GPS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com