Sectioned-anode pulse plasma thruster with high specific impulse

A pulsed plasma and thruster technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of no electrode optimization scheme, unsatisfactory optimization effect, unclear acceleration mechanism, etc., to achieve strengthened constraints, Good constriction and the effect of increasing the current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

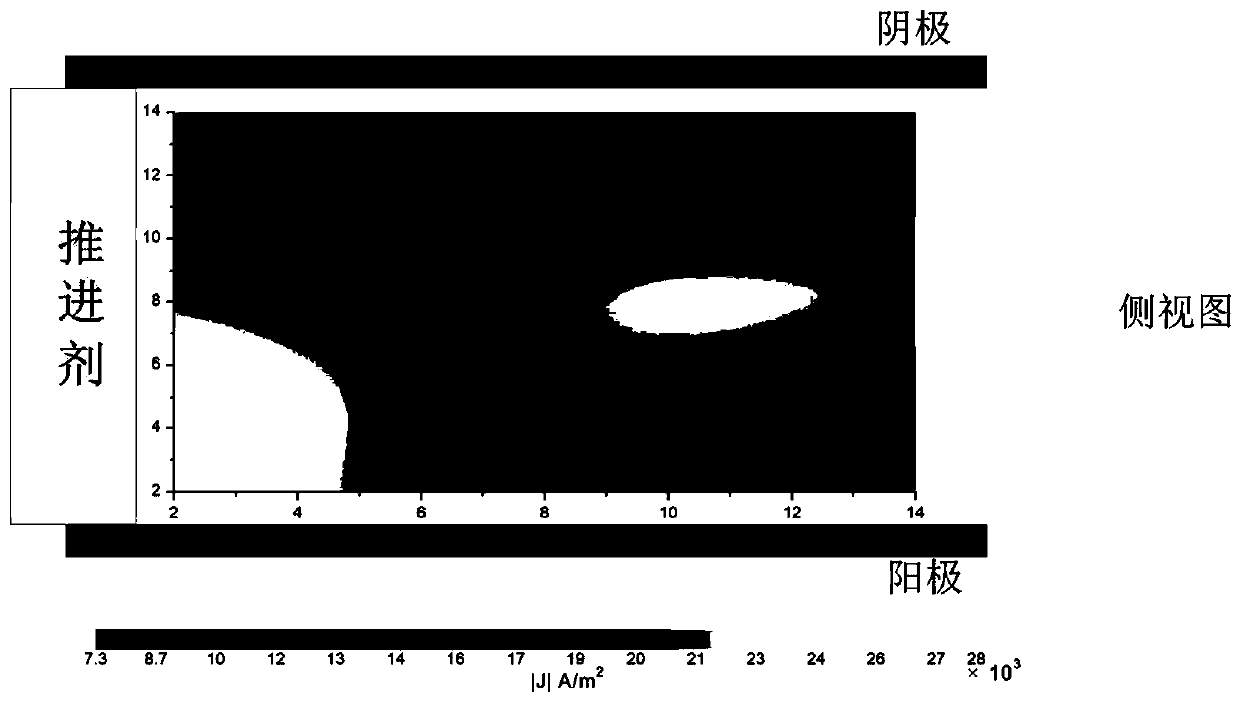

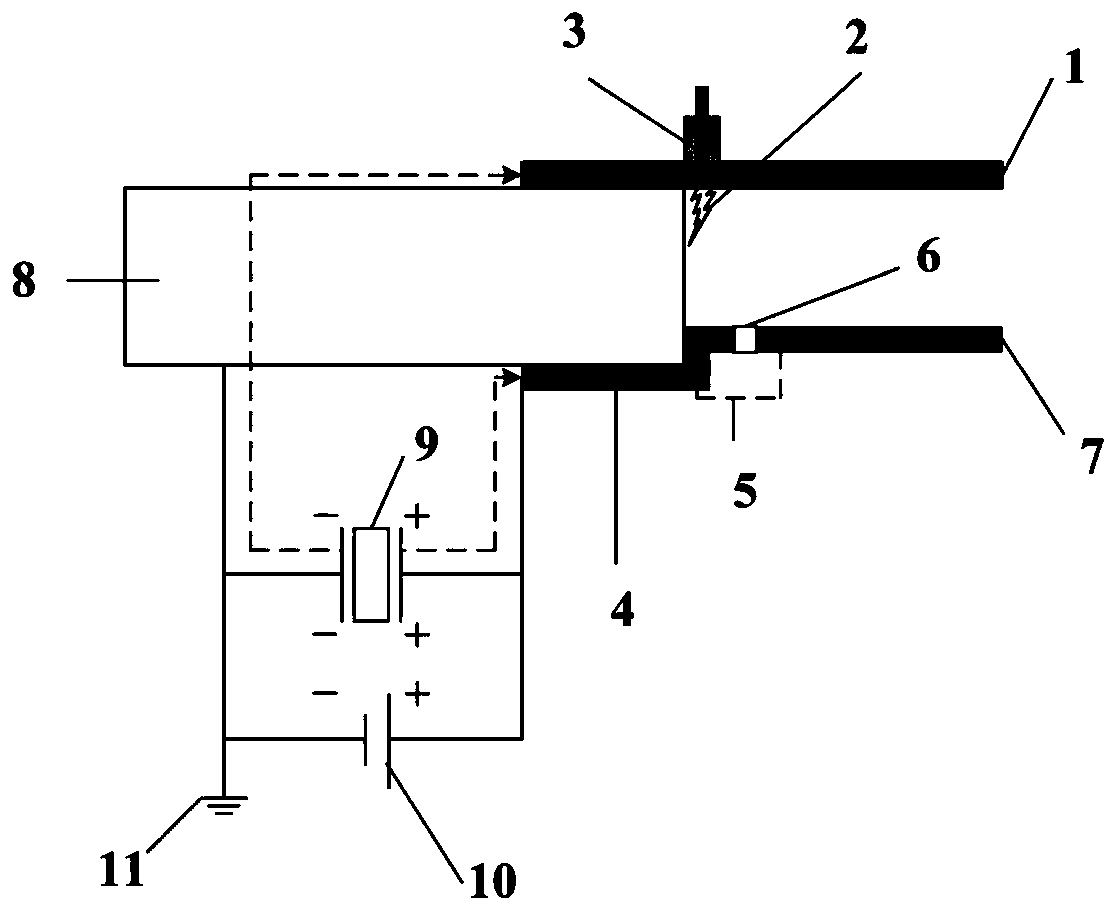

[0020] A schematic diagram of a segmented anode high specific impulse pulse plasma thruster provided by the present invention, as figure 2 , including cathode 1, arc 2, spark plug 3, upstream anode 4, wire 5, insulating block 6, downstream anode 7, propellant 8, energy storage capacitor 9, power supply 10, and ground 11. The power supply 10 loads 2000V high voltage on the energy storage capacitor 9, the energy storage capacitor 9 is an oil-immersed capacitor with a capacitance of 10 μF; both ends of the energy storage capacitor 9 are connected to the cathode 1 and the upstream anode 4; electrons are generated through the spark plug 3 to trigger the yin and yang The arc 2 at both ends of the pole, the arc 2 ablates and ionizes the plasma along the surface of the propellant 8; the wire 5 connects the upstream anode 4 and the downstream anode 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com