Circulating water cooling system of power plant

A circulating water cooling and circulating water system technology, which is applied in the direction of water shower coolers, cooling fluid circulation devices, refrigerators, etc., can solve the problems of difficult cooling effect, fresh cooling water evaporation loss, uneconomical problems, etc., and achieve a wide range of economical Value and practical value, avoid evaporation loss, reduce the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The power plant circulating water cooling system provided by the invention includes: a circulating water system, an ammonia refrigeration system and a temperature monitoring and control system.

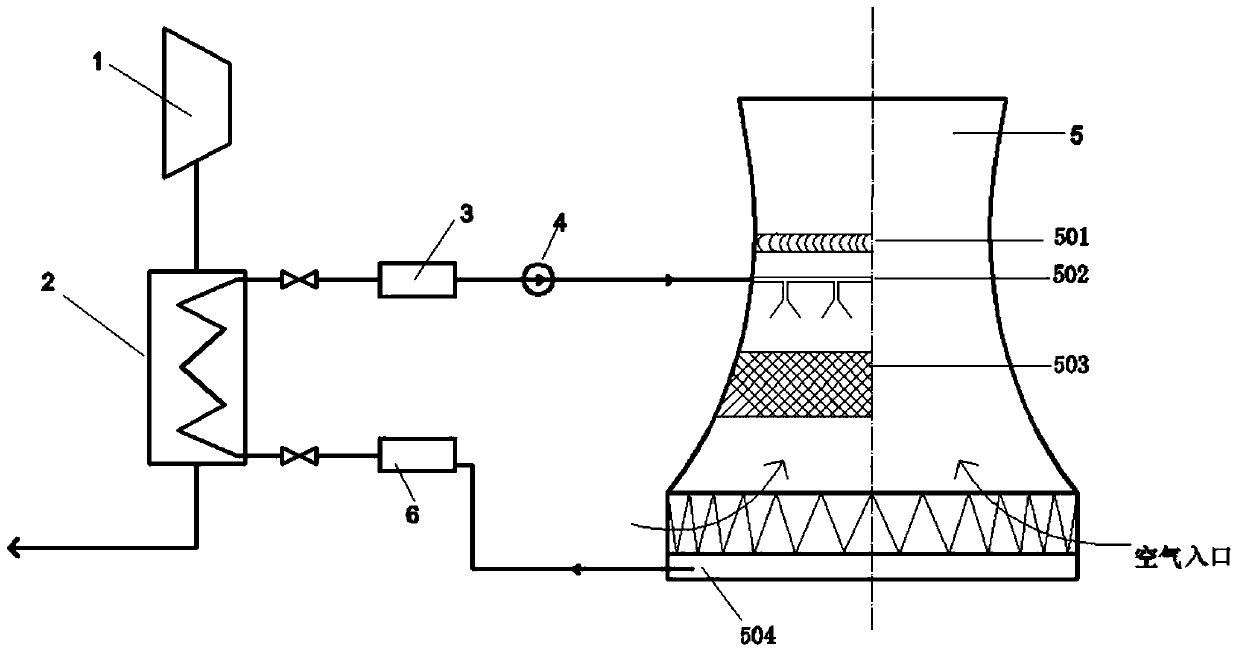

[0037] refer to figure 2 , The circulating water system includes: condenser 2, water collecting tank 3, circulating water pump 4, cooling tower 5, water distribution tank 6 and pipes connecting them. Among them, the condenser 2 is used to cool the exhaust steam after the work of the steam turbine 1, the circulating water outlet of the condenser 2 is connected with the circulating water inlet of the cooling tower 5, and the circulating water outlet of the cooling tower 5 is connected with the circulating water of the condenser 2 The inlet is connected, the water collection tank 3 and the circulating water pump 4 are sequentially arranged on the water inlet pipe of the cooling tower along the water flow direction, and the water distribution tank 6 is arranged on the outlet pipe ...

Embodiment 2

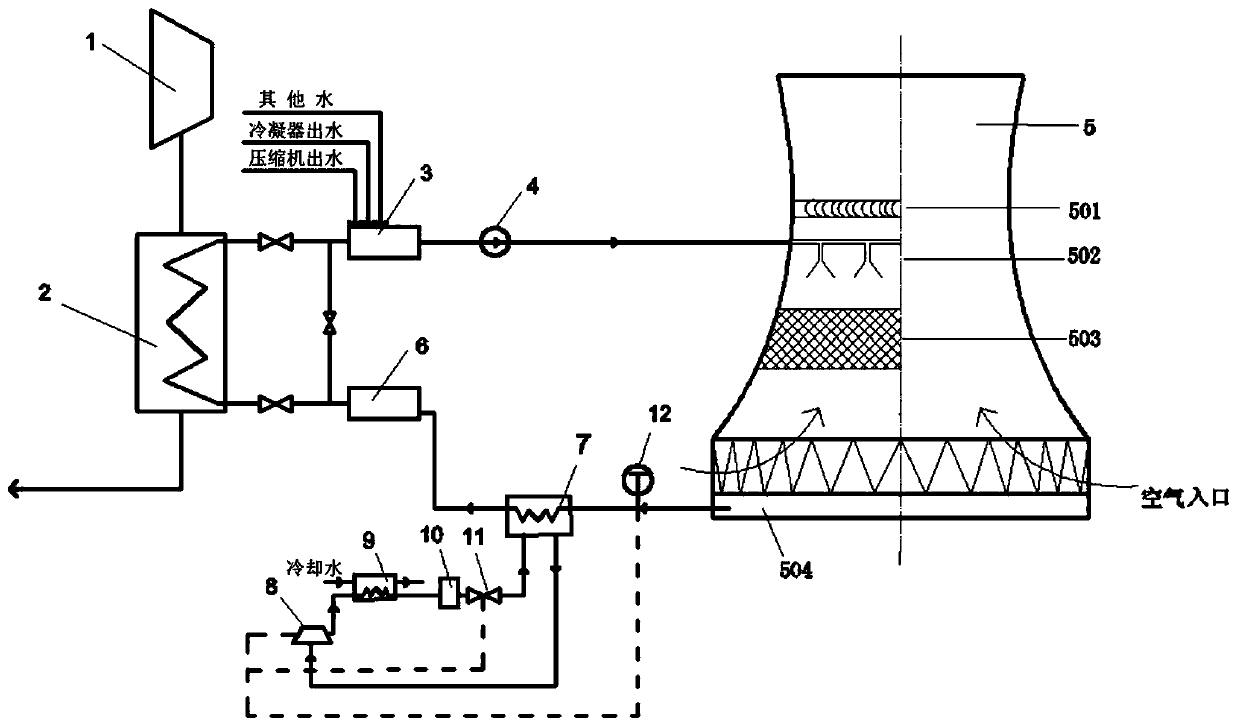

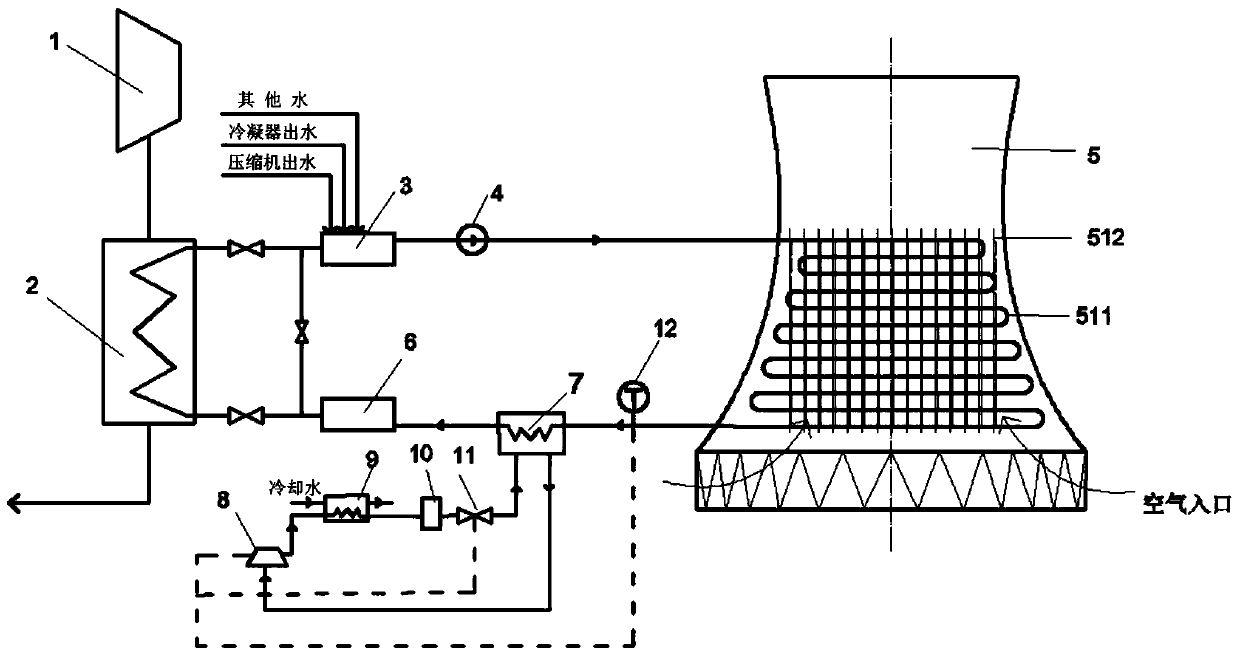

[0051] The power plant circulating water cooling system provided by the invention includes: a circulating water system, an ammonia refrigeration system and a temperature monitoring and control system.

[0052] refer to image 3 , The circulating water system includes: condenser 2, water collecting tank 3, circulating water pump 4, cooling tower 5, water distribution tank 6 and pipes connecting them. Among them, the condenser 2 is used to cool the exhaust steam after the work of the steam turbine 1, the circulating water outlet of the condenser 2 is connected with the circulating water inlet of the cooling tower 5, and the circulating water outlet of the cooling tower 5 is connected with the circulating water of the condenser 2 The inlet is connected, the water collection tank 3 and the circulating water pump 4 are sequentially arranged on the water inlet pipe of the cooling tower along the water flow direction, and the water distribution tank 6 is arranged on the outlet pipe o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com