Metering and transporting device for transporting alternative fuel into kiln tail

A technology of transportation device and alternative fuel, applied in the field of cement industry, can solve the problems of increasing dust concentration, polluting the environment, and unfavorable health of operators, and achieve the effect of increasing dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

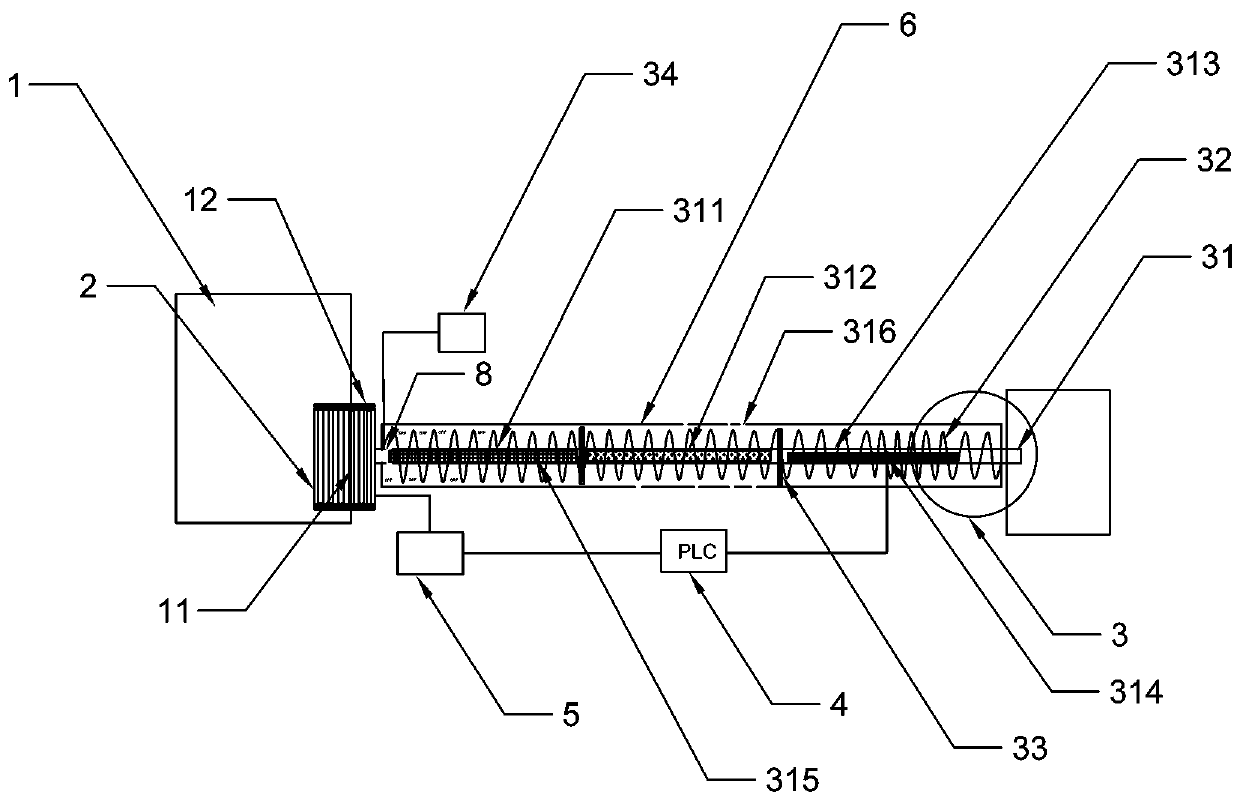

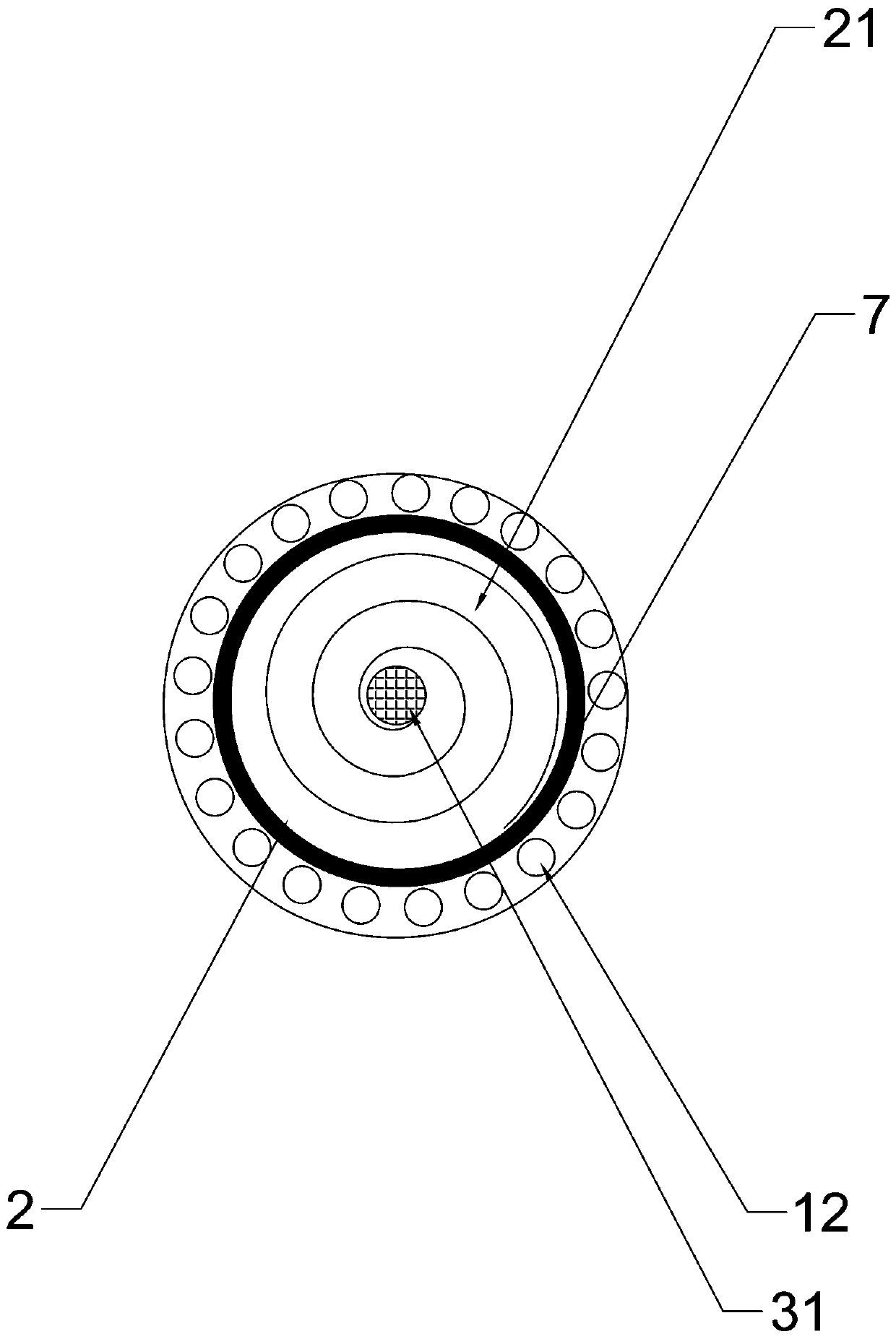

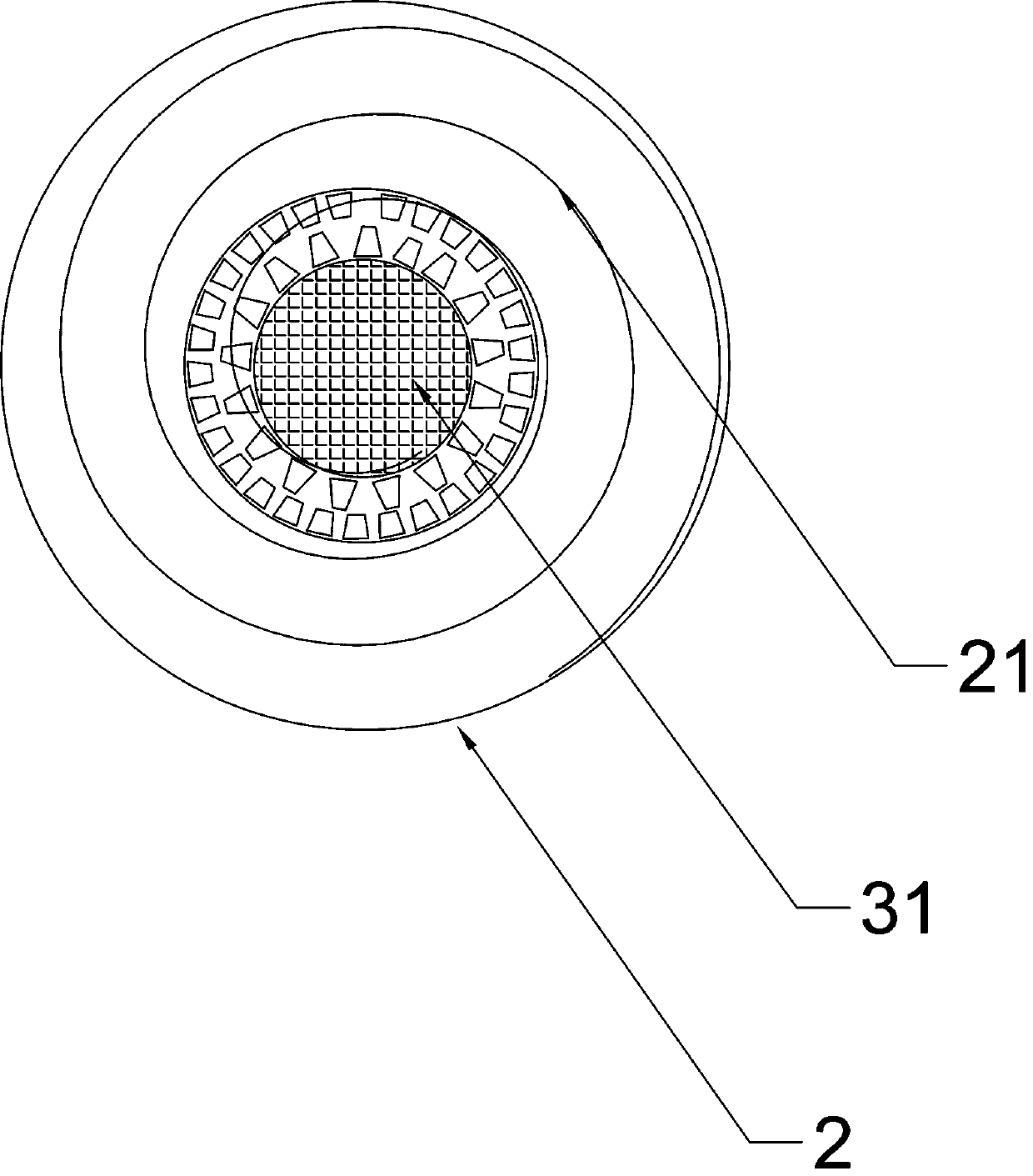

[0024] The present invention provides a metering transport device for transporting alternative fuels into the kiln tail, such as figure 1 As shown, it includes an SRF storage bin 1 with a side end provided with a discharge port 11, and a rotary discharge mechanism 2 partially embedded in the discharge port 11 through a bearing 12. In this embodiment, the rotary discharge mechanism 2 can be As a disc with a vortex channel inside, the outer ring of the bearing 12 is fixed to the discharge port 11, and the inner ring is fixed to the outer wall of the rotary discharge mechanism 2, and the rotary discharge mechanism 2 can be controlled by the motor 5 to rotate, and also includes The auger 3 that is provided with rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com