Wafer lithography device

A lithography equipment and wafer technology, applied in the processing of photosensitive materials, etc., can solve problems such as double-ring defects, backsplash, etc., and achieve the effects of reducing impurities, not easy to remain, and increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

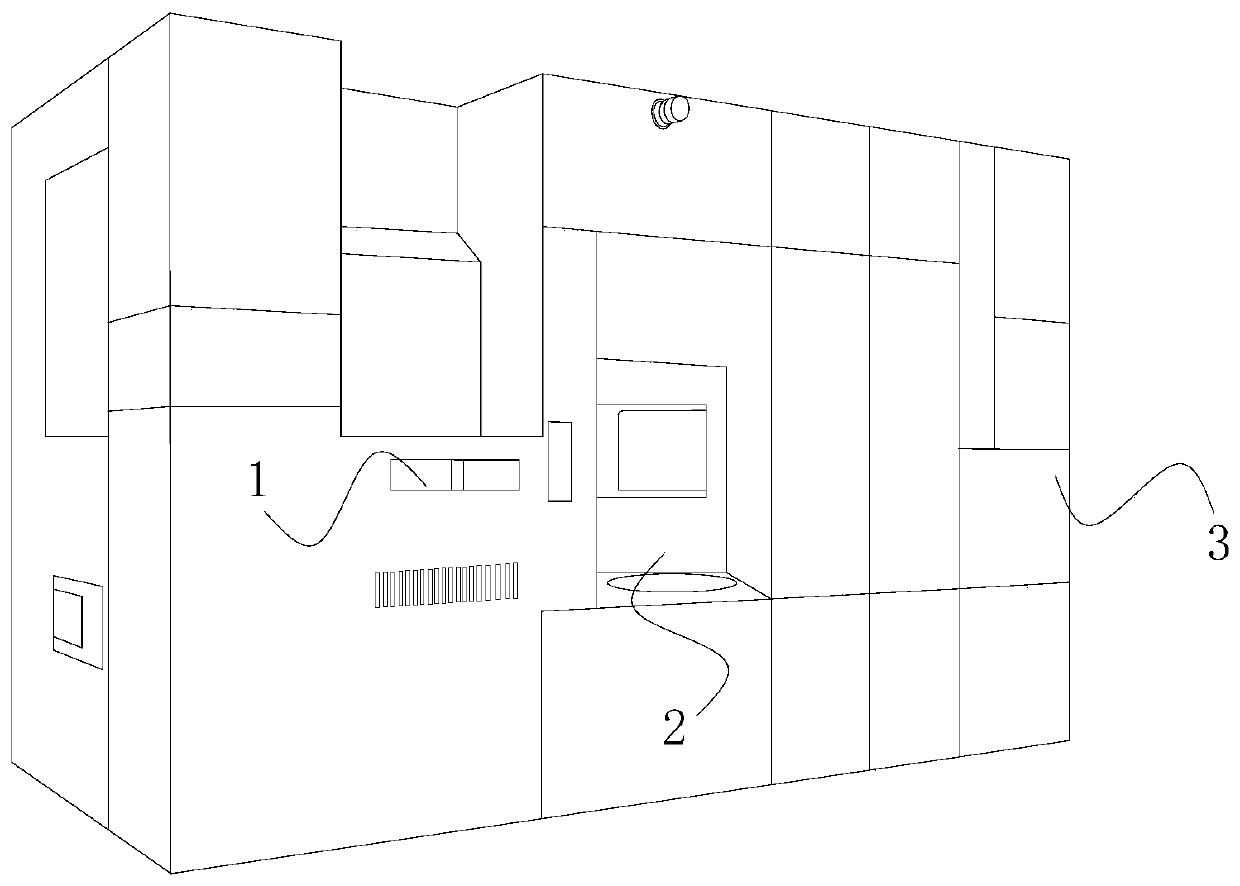

[0026] see Figure 1-Figure 5 , the present invention provides a wafer lithography equipment, the structure of which includes a window 1, an operating table 2, a main body 3, a nozzle structure, a developing tank, an automatic alignment system, a frame damping system, etc., and the main body 3 is provided with a Operating table 2, a window 1 is installed on one side of the operating table 2, a nozzle is installed inside the main body 3, a developing tank is provided at the bottom of the nozzle structure, and an automatic alignment system is provided on the horizontal side of the developing tank , A frame damping system is installed directly under the automatic alignment system, and the frame damping system is movably matched with the developing tank.

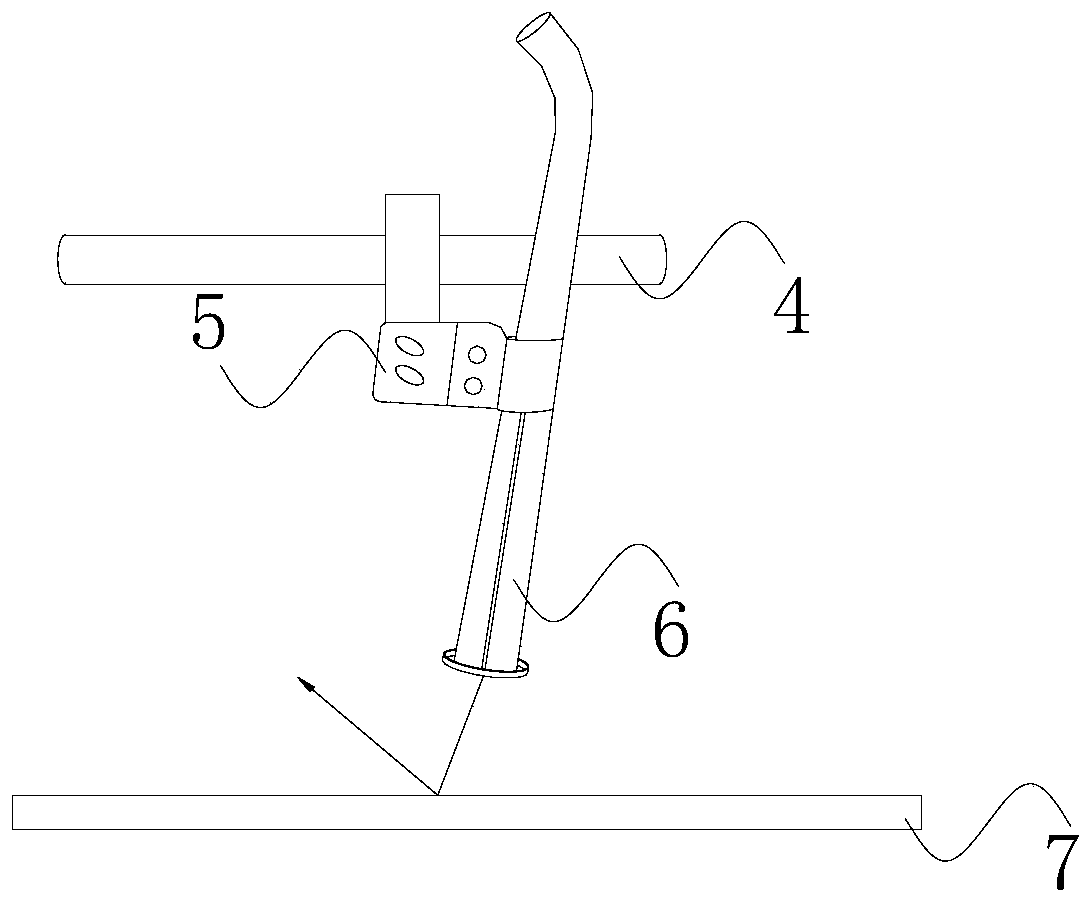

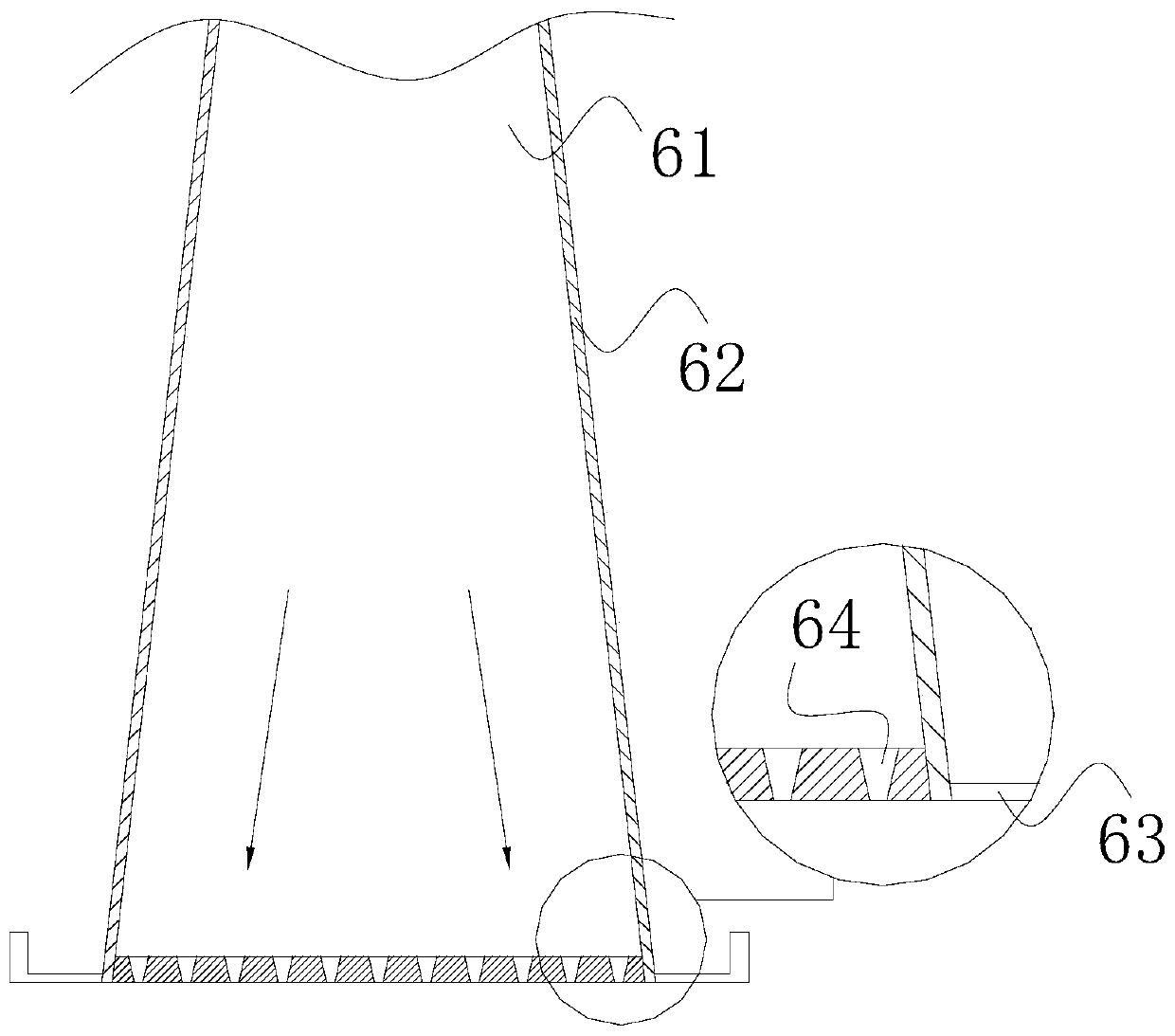

[0027] The nozzle structure is composed of a truss 4, a fixed bracket 5, a nozzle 6, and a CUP board 7. The truss 4 locks the nozzle 6 through the fixed bracket 5, and the nozzle 6 is facing the CUP board 7, and the CUP board 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com