Protection board suitable for mounting over-current protection device PTC

A technology of overcurrent protection device and protection board, applied in the field of powerSupply, to achieve the effect of easy action protection and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

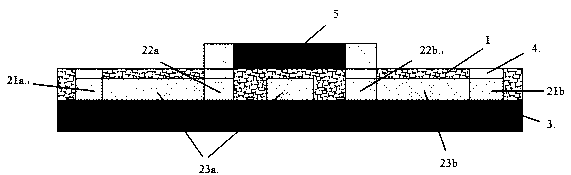

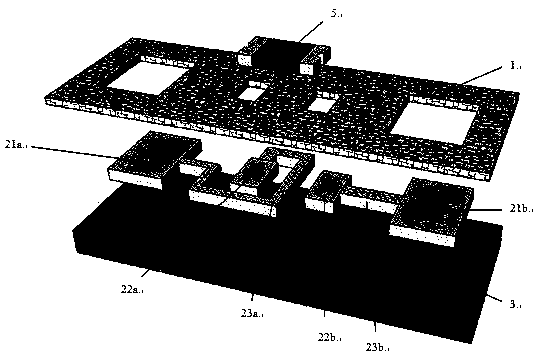

[0040] A protective board suitable for mounting the overcurrent protection device PTC, which only contains one electronic component of PTC 5 and the conductive wire passing through the bottom of the PTC is a test board that passes through all sides on one side, such as figure 1 with figure 2 As shown, it includes a substrate layer 3 and a circuit layer 2. The circuit layer 2 is covered on the surface of the substrate layer 3. The circuit layer 2 includes pads for soldering the pins of each electronic component, conductive wires constituting the circuit, and wires covering the conductive wires. protection layer 1, where,

[0041] Contains a group of pads for welding PTC 5, the first PTC pad 22a, the second PTC pad 22b;

[0042] In this embodiment 1, when the first conductive wire 23a is routed, local wiring is carried out from the middle of the first PTC pad 22a and the second PTC pad 22b where the pins at both ends of the PTC 5 are soldered, that is, it passes through the bo...

Embodiment 2

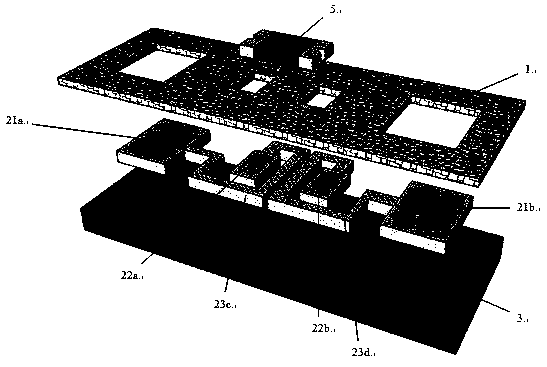

[0048] A protective board suitable for mounting overcurrent protection devices PTC, such as image 3As shown, the conductive wire passing through the bottom of the PTC is a test board with both sides fully passing through, including the substrate layer 3 and the circuit layer 2, the circuit layer 2 covers the surface of the substrate layer 3, and the circuit layer 2 contains soldered electronic components The pads of the pins, the conductive wires constituting the circuit and the protective layer 1 covering the conductive wires, wherein at least one group of first and second PTC pads 22a, 22b for welding PTC 5 are included, the first and second PTC pads 22a, 22b of the present embodiment The second conductive wires 23c and 23d all pass through the middle of the pads where the pins at both ends of the PTC are soldered.

[0049] The only difference between this embodiment and Embodiment 1 is that the routing of the conductive wires is different, such as image 3 As shown, where...

Embodiment 3

[0052] A protective board suitable for mounting overcurrent protection devices PTC, such as Figure 4 As shown, the conductive wire passing through the bottom of the PTC is a single-sided local wiring type test board, including a substrate layer 3 and a circuit layer 2, and the circuit layer 2 is covered on the surface of the substrate layer 3. The circuit layer 2 includes a group for Solder the pads of the PTC, the conductive wires constituting the circuit and the protective layer 1 covering the conductive wires,

[0053] The only difference between this embodiment and Embodiment 1 is that the routing of the conductive wires is different, such as Figure 4 As shown, wherein the first conductive wire 23e goes out from the side wiring of the first pad 22a where the PTC is welded, then goes out between the first and second PTC pads 22a, 22b, and then connects with the first test pad 21a ; The second conductive line 23f is directly connected to the second test pad 21b.

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com