System and method for treating gas containing volatile organic compounds and preparing carbon nanomaterial

A technology of volatile organic compounds and carbon nanomaterials, applied in gas treatment, separation methods, combustible gas purification, etc., can solve problems such as gaseous organic compounds that are difficult to handle, and achieve the effect of reducing CO2 emissions and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

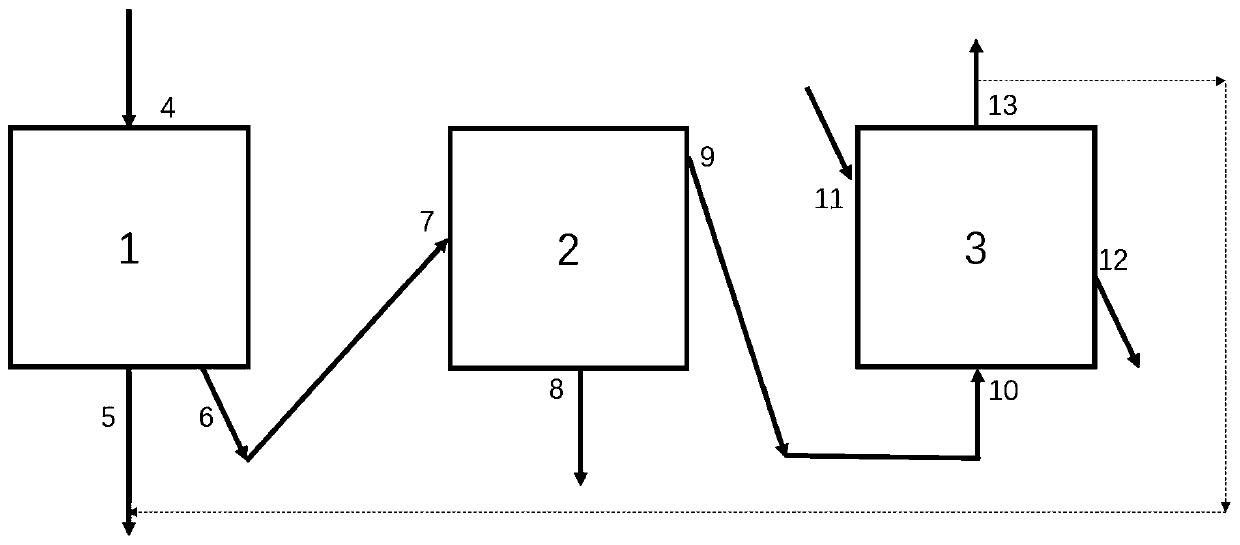

[0030] like figure 1 As shown, the gas adsorption / desorption subsystem 1, the gas-liquid separation subsystem 2, and the tail gas carbonization subsystem 3 are connected in sequence;

[0031] The gas containing volatile organic compounds (the main gas is nitrogen, and the organic matter is 5000ppm C2-C10 hydrocarbons) is introduced from the gas inlet 4 containing volatile organic compounds of the gas adsorption / desorption subsystem 1, the adsorption temperature is -20 ° C, and the pressure is 2MPa, after passing through the adsorbent layer in the gas adsorption / desorption subsystem 1, the organic matter is adsorbed on the adsorbent (the mass fraction is 50% carbon nanotubes and 50% molecular sieve), and the treated argon gas (organic matter is less than 50ppm , aromatic hydrocarbons are lower than 4ppm) the waste gas discharged up to the standard is discharged from the gas outlet 5 after adsorption of the gas adsorption / desorption subsystem 1;

[0032] When the adsorption lay...

Embodiment 2

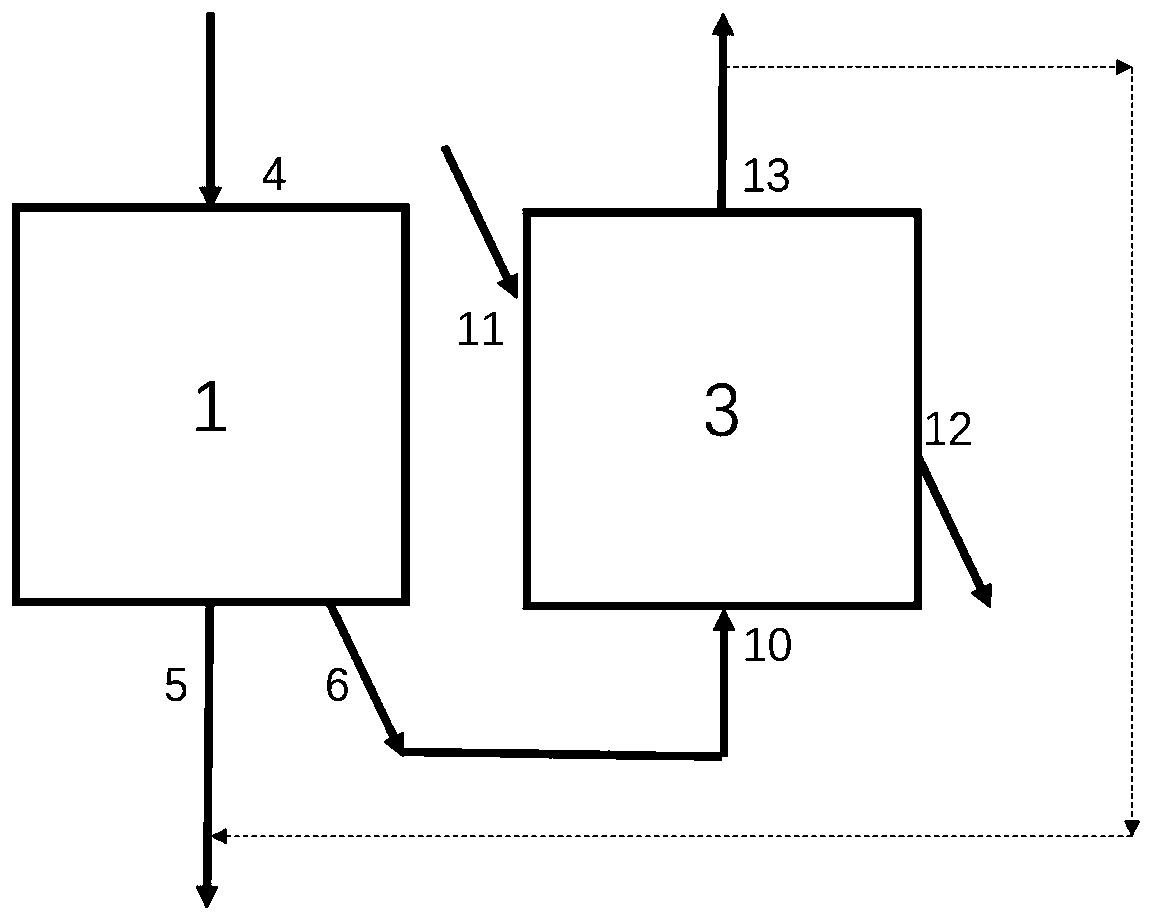

[0036] like figure 2 As shown, the gas adsorption / desorption subsystem 1, the gas-liquid separation subsystem 2, and the tail gas carbonization subsystem 3 are connected in sequence;

[0037] The gas containing volatile organic compounds (the main gas is argon, and the organic matter is 20000ppm C 1 -C 3Alcohol, a mixture of epichlorohydrin in any proportion) is introduced from the gas inlet 4 containing volatile organic compounds of the gas adsorption / desorption subsystem 1, the adsorption temperature is -25-0°C, and the pressure is 2MPa. After gas adsorption / desorption After attaching the adsorbent layer in subsystem 1, the organic matter is adsorbed on the adsorbent (20% activated carbon, 80% graphene), the treated argon (organic matter is less than 1.5ppm), and the exhaust gas that reaches the standard is adsorbed / desorbed from the gas. The gas outlet 5 of the attached subsystem 1 is discharged after adsorption;

[0038] When the adsorption layer of the gas adsorption / ...

Embodiment 3

[0041] like figure 2 As shown, the gas adsorption / desorption subsystem 1, the gas-liquid separation subsystem 2, and the tail gas carbonization subsystem 3 are connected in sequence;

[0042] Argon gas containing volatile organic compounds (the main gas is any mixture of hydrogen and CO, the organic matter is 200,000 ppm of crude oil components with a molecular weight of 200-300) is passed from the gas containing volatile organic compounds of the gas adsorption / desorption subsystem 1. The inlet 4 is passed through, the adsorption temperature is 20 °C, and the pressure is 0.3 MPa. After passing through the adsorbent layer in the gas adsorption / desorption subsystem 1, the organic matter is adsorbed on the adsorbent (graphene), and the treated CO and H2 The waste gas discharged from the mixture (organic matter less than 10ppm) up to the standard is discharged from the gas outlet 5 after adsorption of the gas adsorption / desorption subsystem 1;

[0043] When the adsorption layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com