Reciprocating feeding type medicinal material cleaning and decocting integrated extraction device

A technology of reciprocating material feeding and extraction device, which is applied in the field of extraction device and extraction of traditional Chinese medicine extract, which can solve the problems of lack of integration, synergy, increase of equipment footprint, and large space occupied by equipment, so as to improve process flow , Improve cleaning efficiency and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

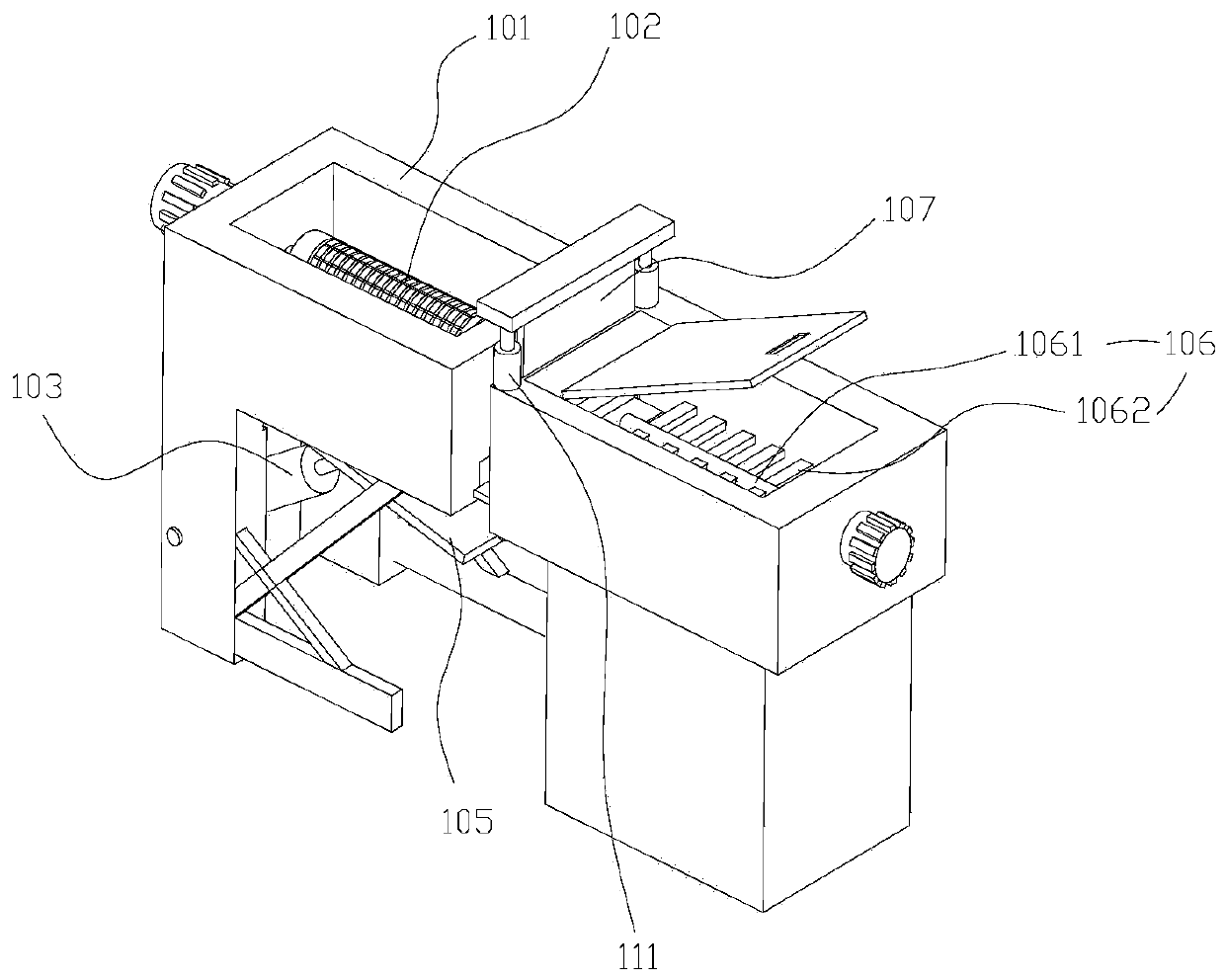

[0053] Such as figure 1 , 2 As shown in . 106 , a valve 107 , a baffle plate 108 , and an elastic member 109 .

[0054] The side of the rotary cylinder 102 is a criss-cross hollow structure and is rotatably connected in the cleaning tank 101. The bottom of the cleaning tank 101 is provided with a first opening, and the bottom plate 105 is hinged at the first opening. The cylinder end of the first cylinder 103 is connected with the cleaning tank 101 The bracket of the pool 101 is hinged, the piston rod end of the first cylinder 103 is hinged upwards with the base plate 105, and the telescopic movement of the piston rod end of the first cylinder 103 drives the base plate 105 to rotate to open and close the first opening.

[0055] Such as figure 2 , 5 , 7, and 8, a first chute 1011 is symmetrically opened on the two inner side walls of the area between the rotating cylinder 102 and the bottom plate 105 in the cleaning pool 101, and a first discharge port is opened at one end...

Embodiment 2

[0068] The difference between this embodiment and the above embodiments is that the end of the cleaning pool 101 opposite to the first outlet 1012 is the starting end of the cleaning pool, and the end to which the first outlet 1012 belongs is the ending end of the cleaning pool 101 . The end of the decocting machine body 106 to which the first feed inlet 1063 belongs is the initial end of the decocting machine body 106 , and the end opposite to the first discharge port 1012 is the terminal end of the decocting machine body 106 .

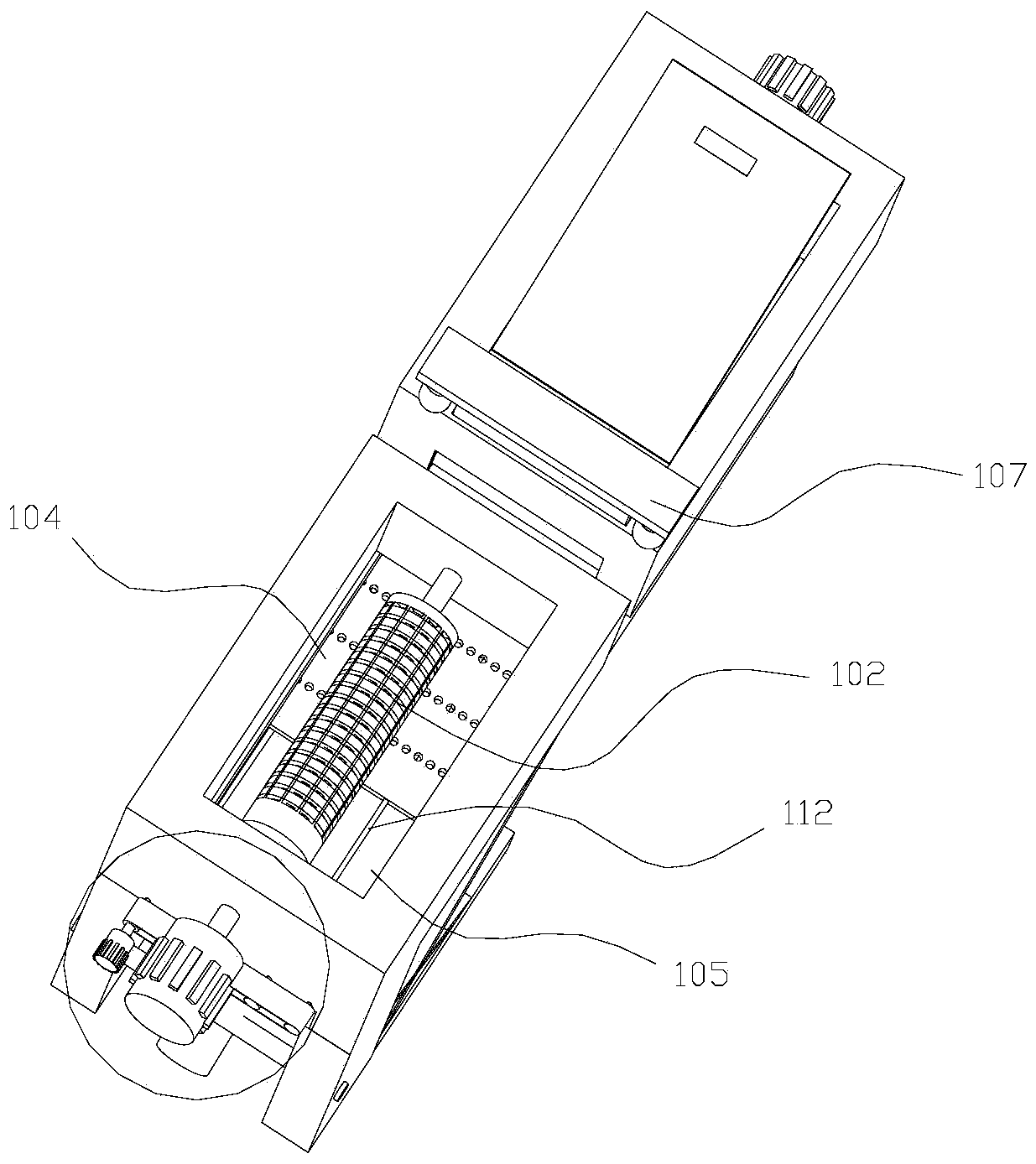

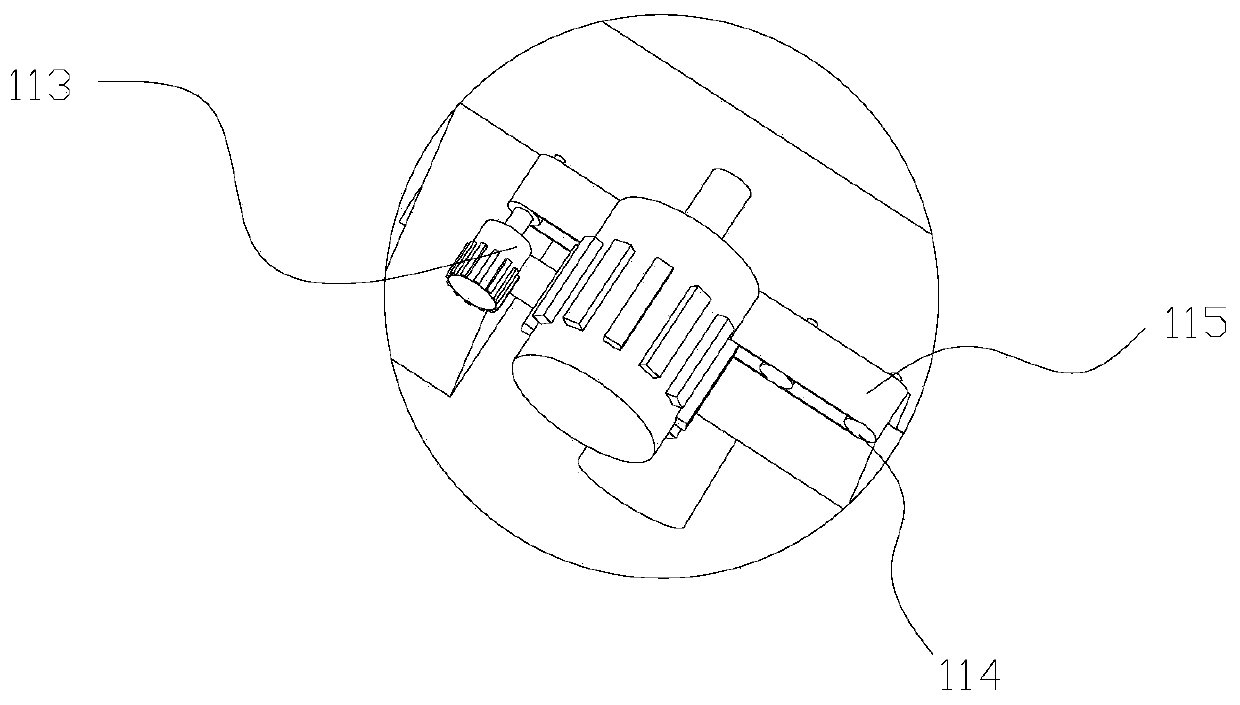

[0069] Such as figure 2 , 3 As shown, it also includes a first screw rod 112 , a first drive motor 113 , a rotating wheel 114 , and a belt 115 . A plurality of first screw rods 112 extend from the starting end of the cleaning tank to the ending end of the decocting machine body 106 . A rotating wheel 114 is sleeved on each first threaded mandrel 112 , and a plurality of rotating wheels 114 are linked by a belt 115 . The output shaft of the first d...

Embodiment 3

[0073] Such as Figure 9 , 10 As shown, the difference between this embodiment and the above embodiments is that it also includes a sewage settling device, which is located below the cleaning tank 101 and includes a settling tank 1161 , a push plate 1162 , and a third cylinder 1163 . The push plate 1162 is set in the settling tank 1161, and its side and bottom surface are respectively provided with rubber sealing strips, which are in sealing contact with the inner side wall and inner bottom wall of the settling tank 1161 through rubber sealing strips, and the push plate 1162 can be horizontally moved from the starting end of the settling tank 1161 Sliding to the terminal end of the settling tank 1161, a water falling cavity 1164 with a first opening at the top is formed between the push plate 1162, the inner side wall and the inner bottom wall of the settling tank 1161. The sewage flowing out from the first opening in the open state can fall into the water falling cavity 1164...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com