Optical fiber composite light spot laser beam combiner and manufacturing method thereof

A laser beam combiner and optical fiber composite technology, which is applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of high cost, inability to modulate, and reduce the reliability of optical fibers, so as to save costs, improve reliability, The effect of reducing internal porosity in welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

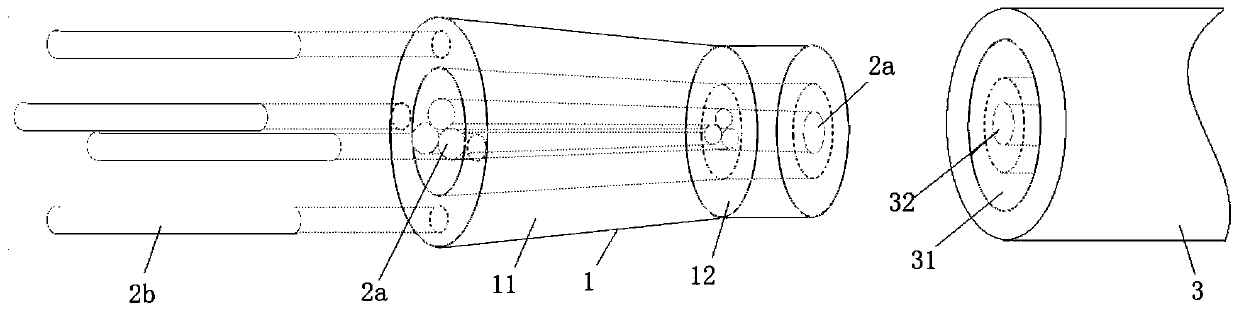

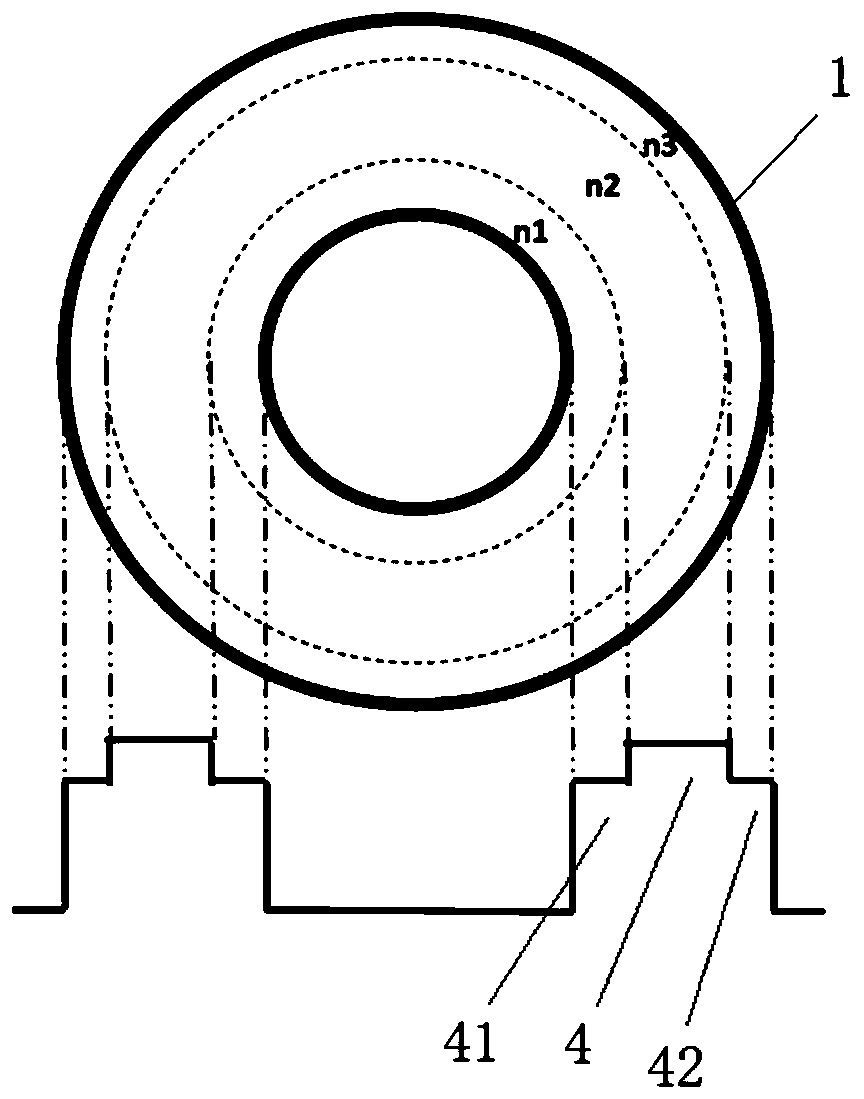

[0032] refer to figure 1 As shown, the present embodiment is an optical fiber composite spot laser beam combiner, which includes a hollow tapered tubular glass waveguide, several outer ring input optical fibers 2b uniformly welded on the section of the tube wall 11 of the tubular glass waveguide 1, and a beam combiner A number of central input optical fibers 2a placed in the center of the tubular glass waveguide 1, and a large mode field optical transmission optical fiber 3 located at the tapered end of the tube wall of the tubular glass waveguide and fused and condensed;

[0033] The large mode field optical transmission fiber 3 includes a ring-type waveguide connection end 31 corresponding to the tapered end of the tube wall 11 of the tubular glass waveguide 1, and correspondingly matched with the central input optical fiber 2a bundled at the center of the tubular glass waveguide 1 The connection fiber 32.

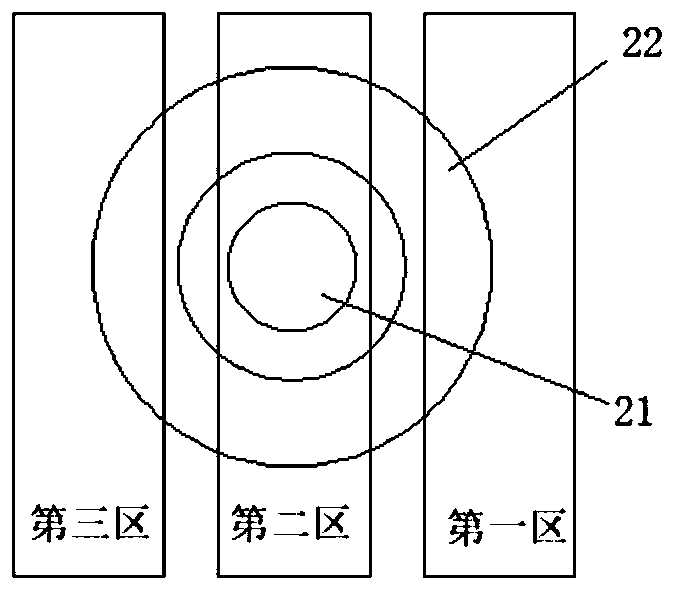

[0034] A number of central input optical fibers 2a combine the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com