Bell-type transformer oil tank lower-section bent bottom plate hole-forming tool

A technology for transformer oil tanks and bell jars, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of increased welding difficulty, roughness, jagged cutting surface, etc., to improve the quality of opening holes, work efficiency, and operation The effect of simplicity, flexibility and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

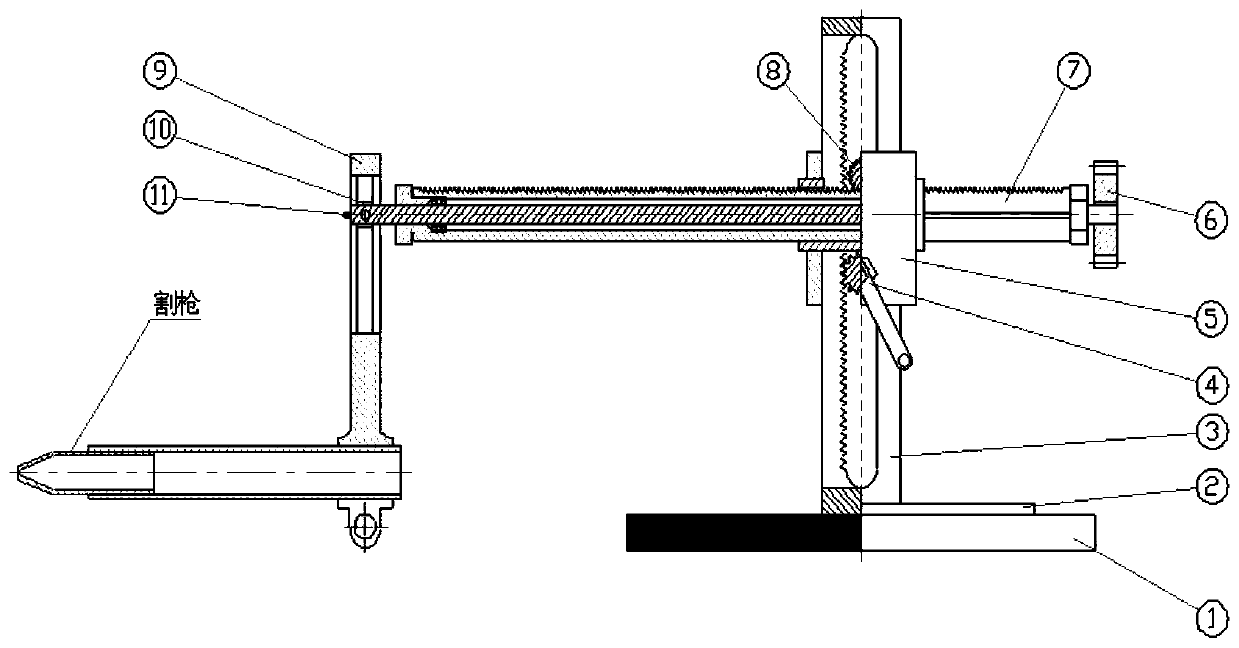

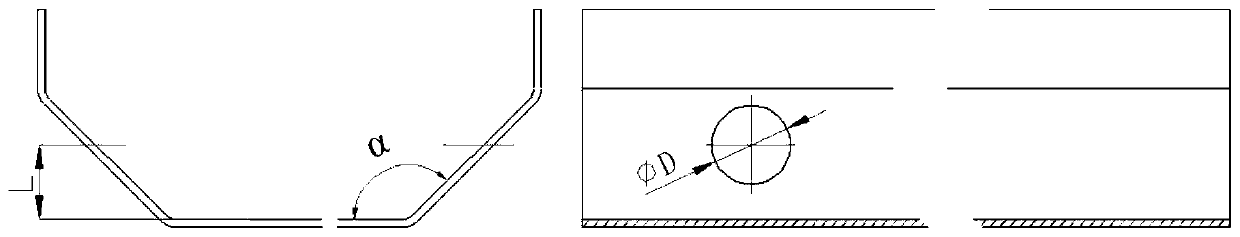

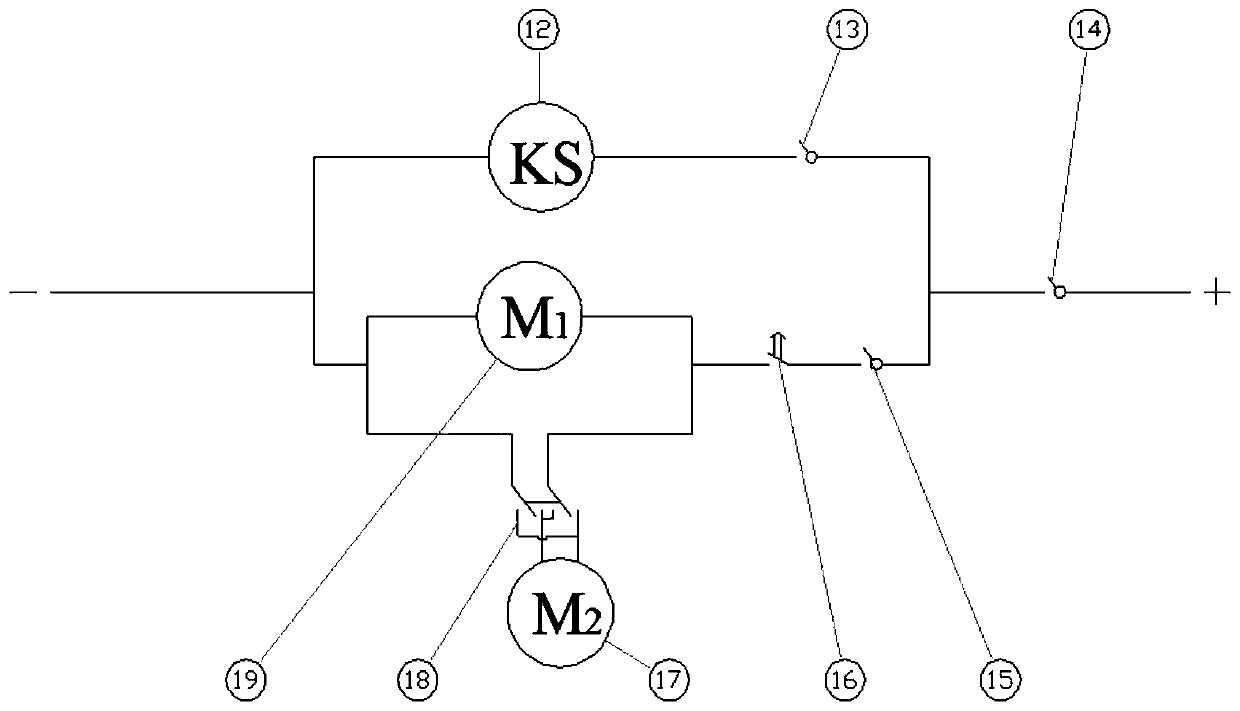

[0024] Such as Figure 1-9 As shown, the present invention provides a technical solution: a tool for opening holes in the lower section of the bell-type transformer oil tank, including an electromagnet base 1, an electrical control system 2, a Y-direction moving guide rail 3, and a Y-direction driving gear set 4 , slider A5, rotating driving gear 6 around X direction, moving and rotating structure group 7 in X direction, driving gear group 8 in X direction, torch clamping device 9, fixing bolt group 10 and laser pointer 11, the electromagnet base 1 The whole device is fixedly installed on the plane of the bottom plate of the lower section, the electrical control system 2 is electrically connected with the torch, the Y-direction moving guide rail 3 is provided with a high-preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com