Multifunctional pressing machine

A pressing machine and multi-functional technology, applied in the field of pressing processing, can solve the problems of worker fatigue and physical injury, difficult to guarantee product consistency, uncontrollable pressing force, etc., to achieve convenient disassembly and replacement, versatility Powerful, mobile-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

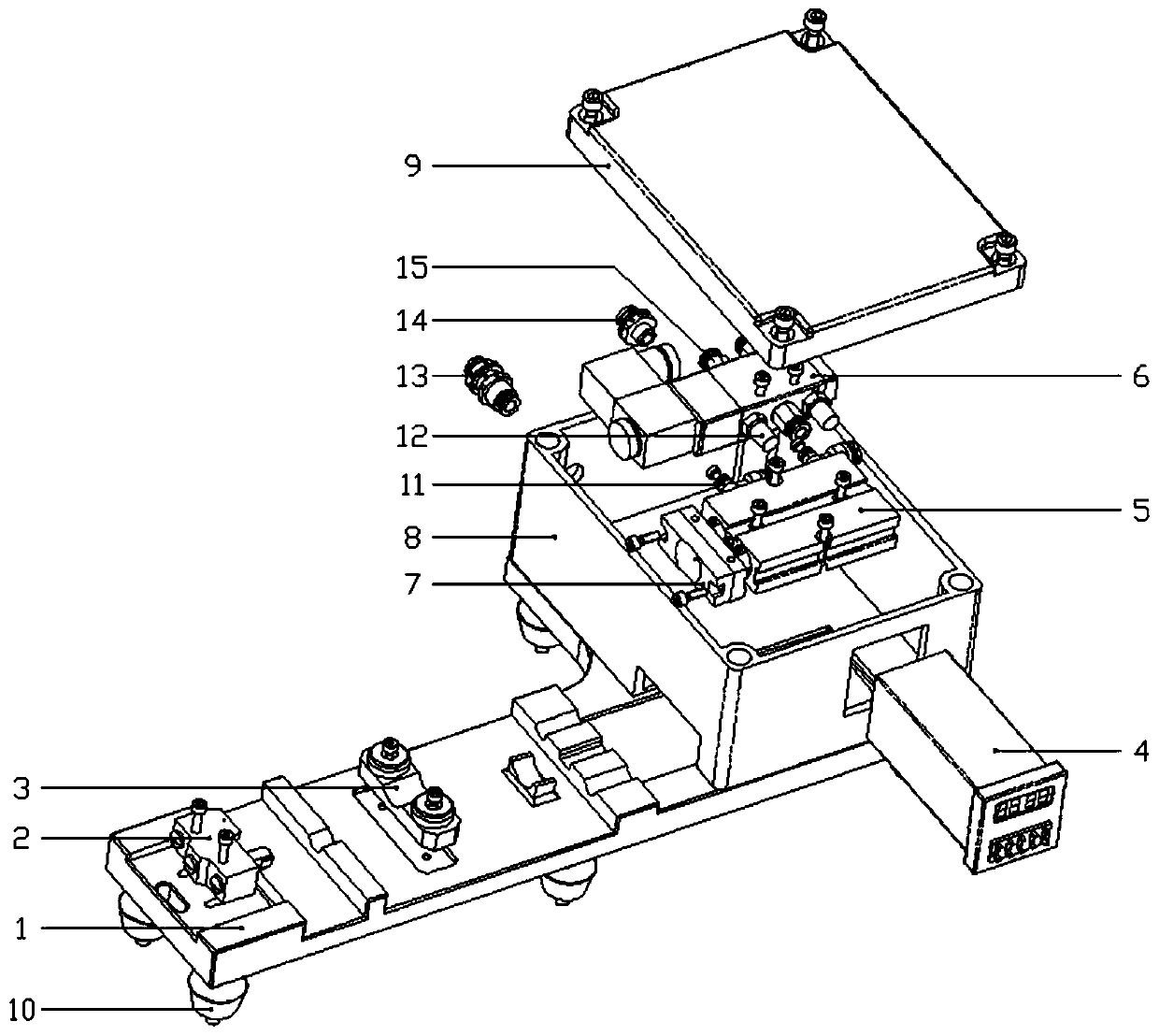

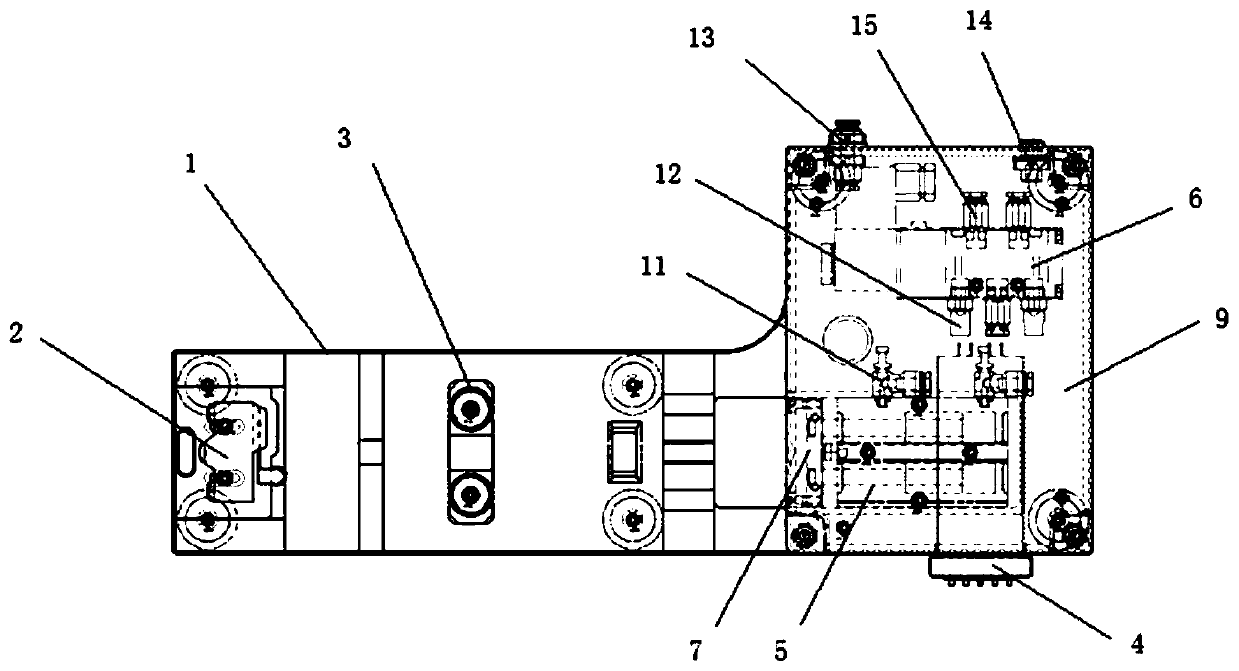

Image

Examples

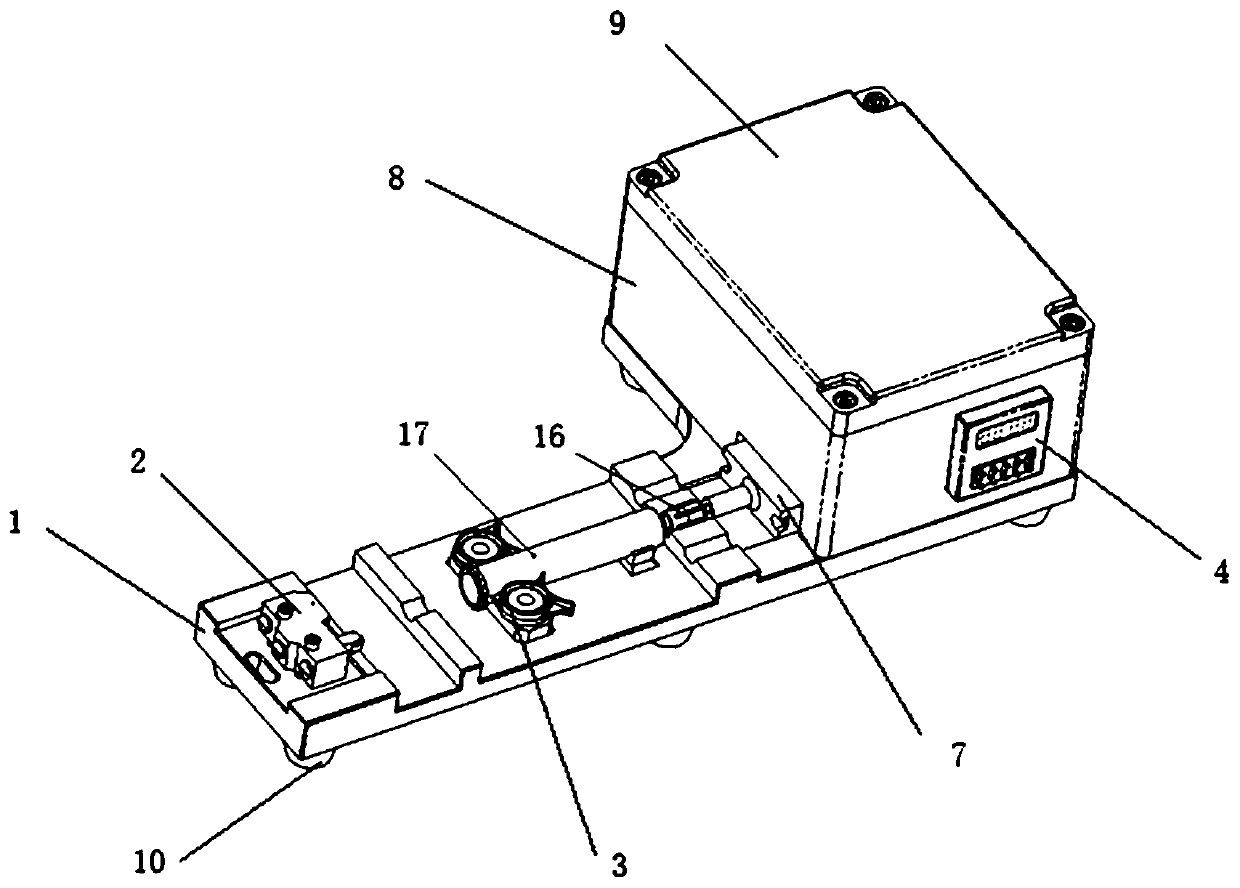

Embodiment 1

[0068] Such as figure 2As shown, first assemble all the accessories, connect the gas circuit and circuit, adjust the size of the gas source through the L-shaped throttle valve 11, and adjust the pressure holding time after the biaxial cylinder 5 is pushed through the time relay 4; the pressure of the gas source and the time After debugging, the luer connector 16 and the ring handle syringe body 17 are pre-assembled together and put into the pressing machine. At this time, the two parts have been positioned in the front, back, left, and right directions and cannot be moved, and the operator can leave the product to go. The micro switch 2 is actively triggered. After the micro switch 2 is triggered, the biaxial cylinder 5 advances and moves back after holding the pressure for 2 seconds, and a production cycle is completed.

[0069] Such as Figure 18 As shown, first assemble all the accessories, connect the gas circuit and circuit, adjust the size of the gas source through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com