A prefabricated thermal insulation wall

A thermal insulation wall, prefabricated assembly technology, applied in the direction of thermal insulation, building thermal insulation materials, fire prevention, etc., can solve the problems affecting the safety and stability of the wall, poor thermal insulation performance, wall erosion, etc., to achieve accurate connection and positioning, Easy operation and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

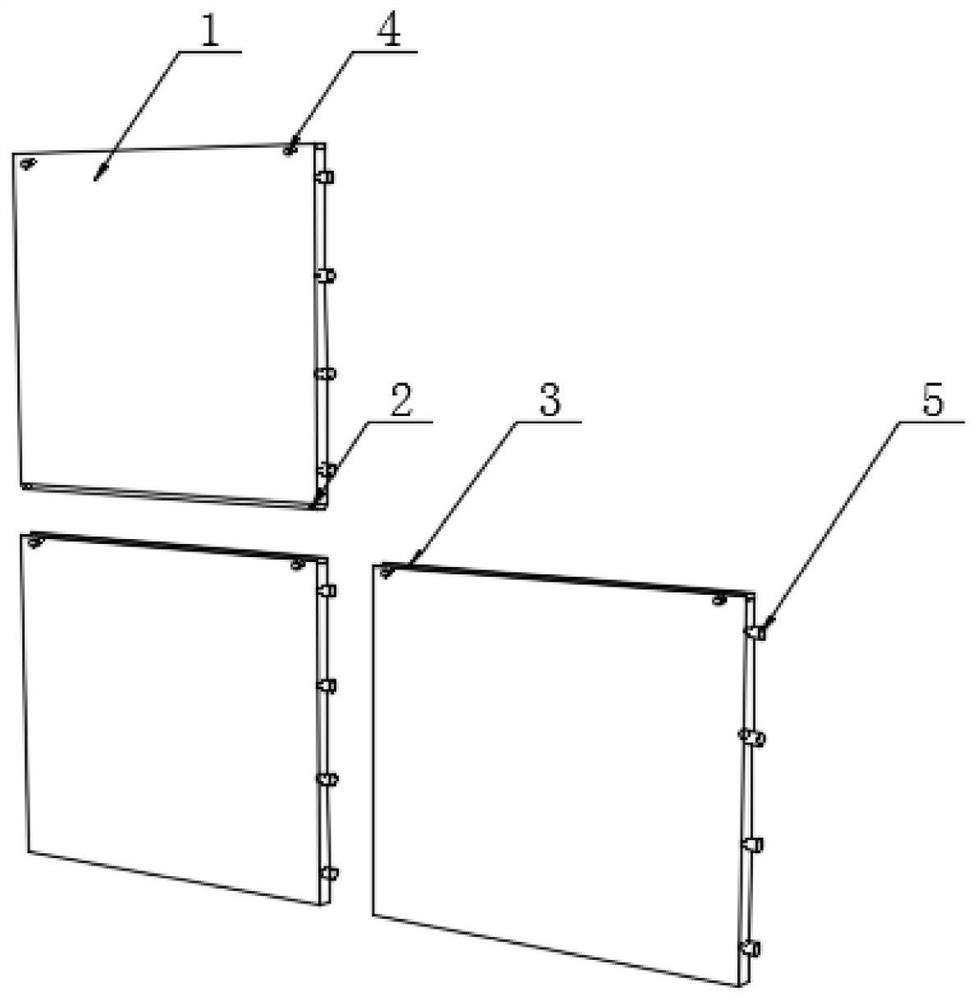

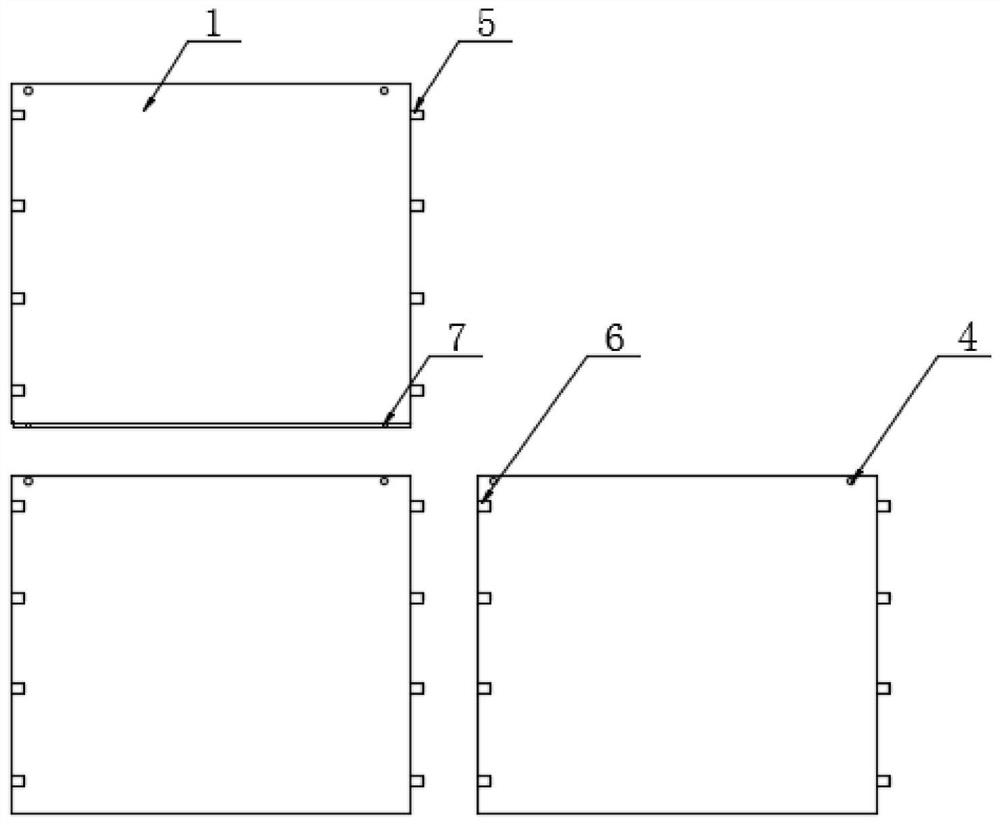

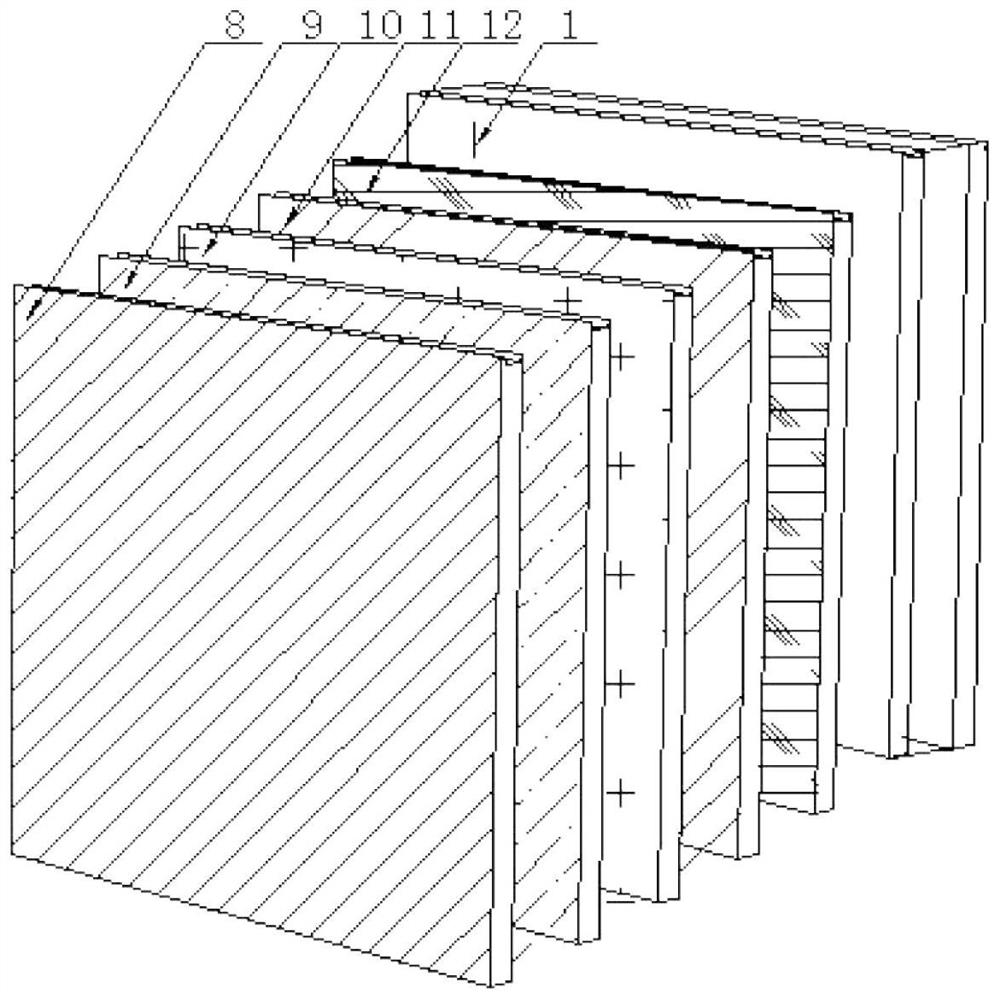

[0025] see Figure 1~6 , in an embodiment of the present invention, a prefabricated thermal insulation wall, including a wall support body 1, an external thermal insulation protection component, a support beam 20, a mortise and tenon mechanism, and a joint external sealing mechanism, wherein the adjacent walls The body support bodies 1 are riveted together by the mortise and tenon mechanism, and the wall support body 1 at the end can be connected and fixed on the support beam 20, and the outer body surface of the wall support body 1 And / or the surface of the inner main body is fixedly provided with the external thermal protection assembly; it is characterized in that the joint between two adjacent wall support bodies 1 is also provided with the joint outer sealing mechanism, and the joint The outer sealing mechanism includes an I-shaped tension member 16 and a sealing expansion layer 17, wherein the horizontal cross section of the I-shaped tension member 16 is an I-shaped stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com