Sucker rod with oil pipe traction device and casing

A technology of traction device and sucker rod, which is applied in the direction of casing, drill pipe, drill pipe, etc., can solve the problem of low oil yield, achieve the effect of increasing oil yield and expanding oil production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

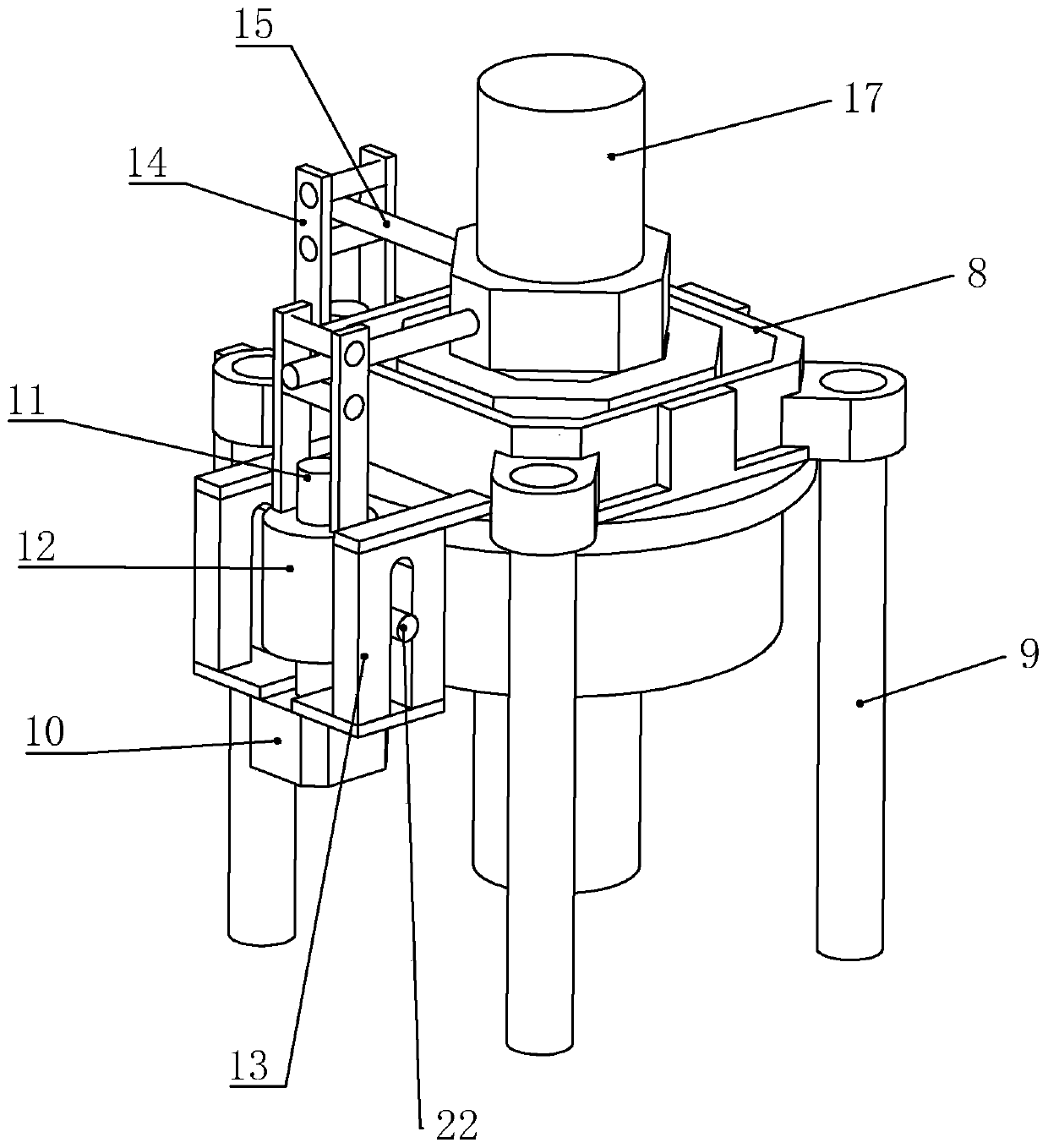

[0029] The steering mechanism includes a mounting base 8, a gyroscope, an X-axis steering assembly and a Y-axis steering assembly. The bottom of the mounting base 8 is provided with a strut 9, and is suspended at the center of the housing 5 in the forward direction by the strut 9. The link 20 is fixed at the center of the mount 8 by a gyroscope, the X-axis steering assembly and the Y-axis steering assembly are arranged on both sides adjacent to the mount 8, and the X-axis steering assembly includes an azimuth motor 10, a screw 11, and a screw sleeve 12 , limit bracket 13, jacket 14 and cross bar 15, one end of cross bar 15 is connected on the connecting rod 20, azimuth motor 10 and limit bracket 13 are fixed on the mount 8, and one end of screw mandrel 11 is connected with azimuth motor 10 The output shaft is fixedly connected, the other end is threadedly connected with the screw sleeve 12, the outer peripheral surface of the screw sleeve 12 is provided with a limit rod 22, the...

Embodiment 2

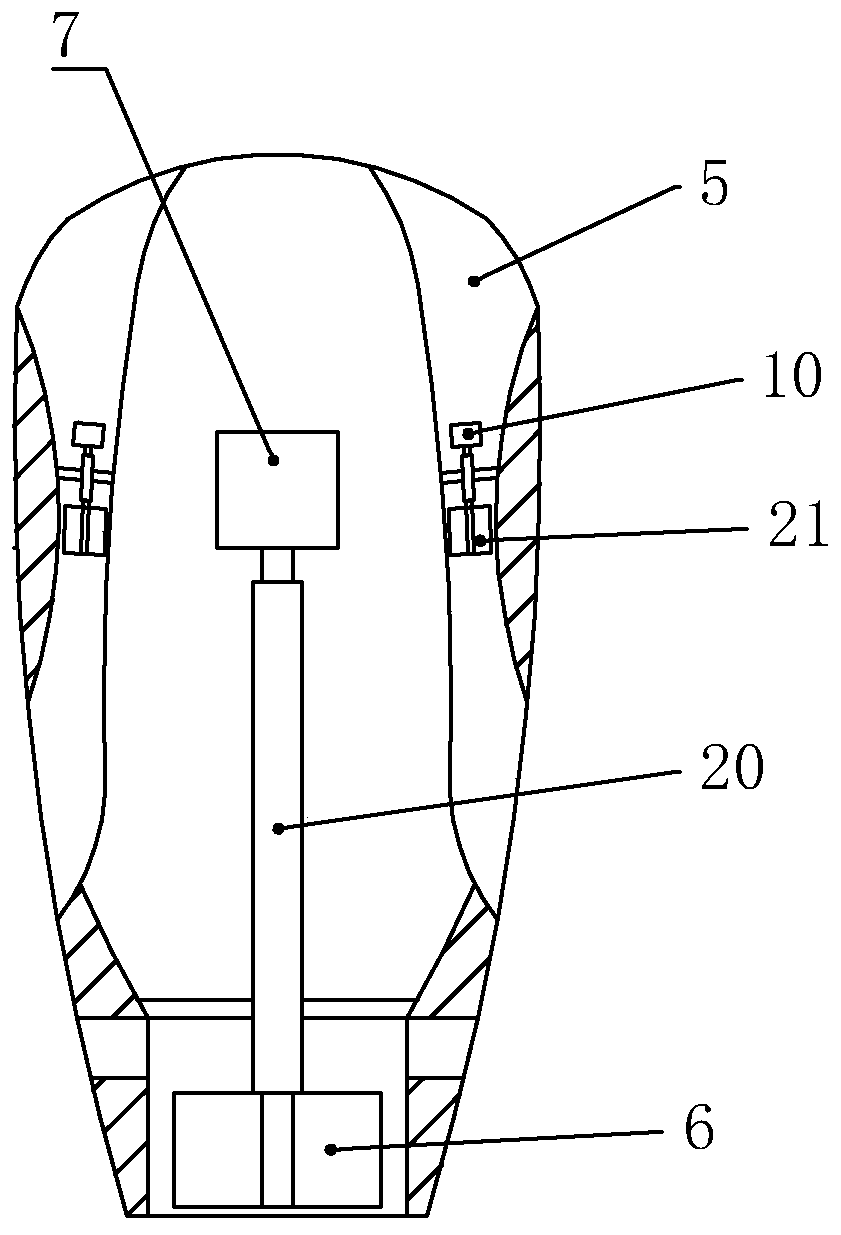

[0032] Through holes are respectively arranged around the housing 5 , and a steering mechanism is provided in each through hole. The steering mechanism includes an azimuth motor 10 and a steering turbine 21 , and the steering turbine 21 is connected to the output shaft of the azimuth motor 10 . In this embodiment, the effect of changing the orientation is achieved by adding power assistance to the side of the housing 5. When the housing 5 moves in the horizontal direction, the housing 5 needs to move upwards, and the azimuth motor 10 below the housing 5 starts to drive the steering turbine 21 to rotate. , so as to push the housing 5 to move upwards, the housing 5 needs to be moved downwards, and the azimuth motor 10 above the housing 5 starts to drive the steering wheel 21 to rotate, pushing the housing 5 to move downwards.

Embodiment 3

[0034]The housing 5 is respectively provided with a rotatable side wing on both sides near the tail, and the top of the housing 5 is provided with a rotatable ridge wing. The steering mechanism includes two side wing motors and a ridge wing motor, and the side wing is provided with a side wing shaft. , the other end of the wing rotating shaft is fixedly connected with the output shaft of the wing motor, the ridge wing is provided with a ridge wing rotating shaft, and the other end of the ridge wing rotating shaft is fixedly connected with the output shaft of the ridge wing motor. This embodiment utilizes the principle of an airplane wing to achieve the effect of changing the moving direction of the housing 5 by changing the direction of the side wings or ridge wings. Both the wing motor and the side wing motor use servo motors, and the control accuracy is high.

[0035] The casing 5 is provided with a storage battery, which is electrically connected to the motor, and the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com