Radioactive waste curing method and application thereof

A technology of radioactive waste and solidification method, which is applied in radioactive purification, nuclear engineering and other directions, can solve the problems of rising disposal costs and increasing the volume of waste packages, and achieve the effects of improved anti-leaching performance, large waste containment rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

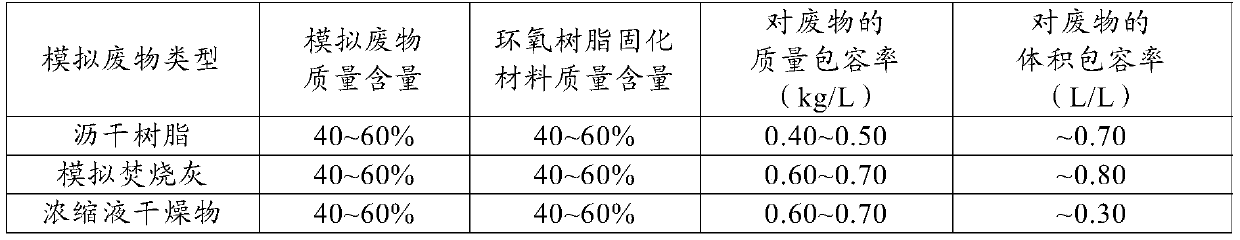

Examples

Embodiment 1

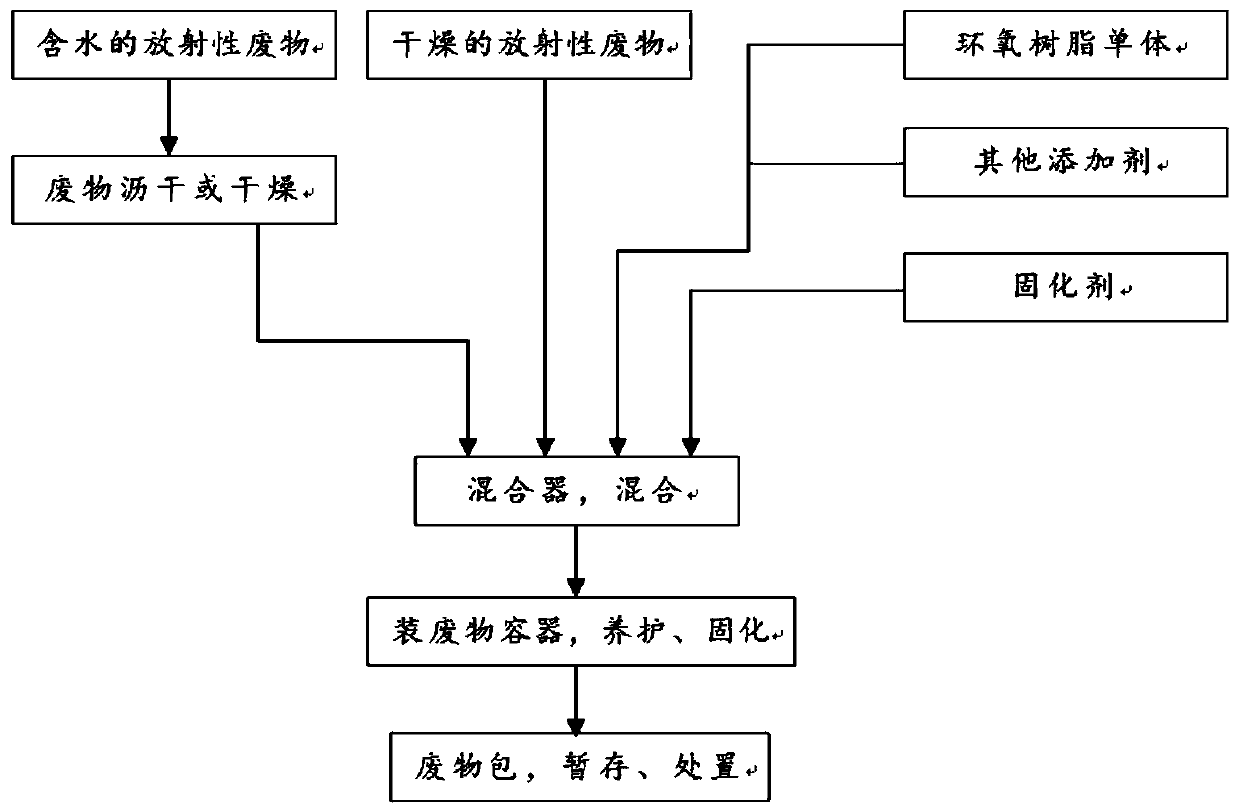

[0033] like figure 1 Shown, the solidification method of the radioactive waste in the present embodiment comprises the following steps:

[0034] (1) Dehydration or drying of radioactive waste

[0035] If the radioactive waste contains a lot of free water, it needs to be dehydrated or dried before solidification; if the radioactive waste does not contain water, the following step (2) can be directly performed.

[0036] When the radioactive waste contains a lot of free water (such as waste resin, waste filter media, liquid concentrates and sediments transported by flushing and drainage), this method may not be able to solidify, so it is necessary to use draining before solidification. Dry or desiccated method for dehydration. Dehydration or drying can be carried out by means of filtration, negative pressure suction or evaporation according to different radioactive wastes. Specifically, in this embodiment, dehydration or drying is performed by draining or drying waste.

[003...

Embodiment 2

[0049] This embodiment provides a kind of curing that is applicable to the processed radioactive material (such as dried concentrated solution) that contains higher strong oxidizing agent (such as sodium nitrate), and the difference with the curing method in embodiment 1 is:

[0050] (1) Add flame retardant

[0051]In the step (2) of embodiment 1, according to containing higher strong oxidizing agent (such as containing more sodium nitrate concentrate etc.) To slow down the combustion performance of the final epoxy resin waste cured body. The flame retardant type adopts aluminum hydroxide flame retardant. The amount of the flame retardant is 40% of the total mass of the epoxy resin cured material.

[0052] It should be pointed out that the combustion performance of epoxy resin waste cured body is related to the characteristics of radioactive waste. body, it will burn violently and continuously after being ignited with fire. After adding a flame retardant to the epoxy resin...

Embodiment 3

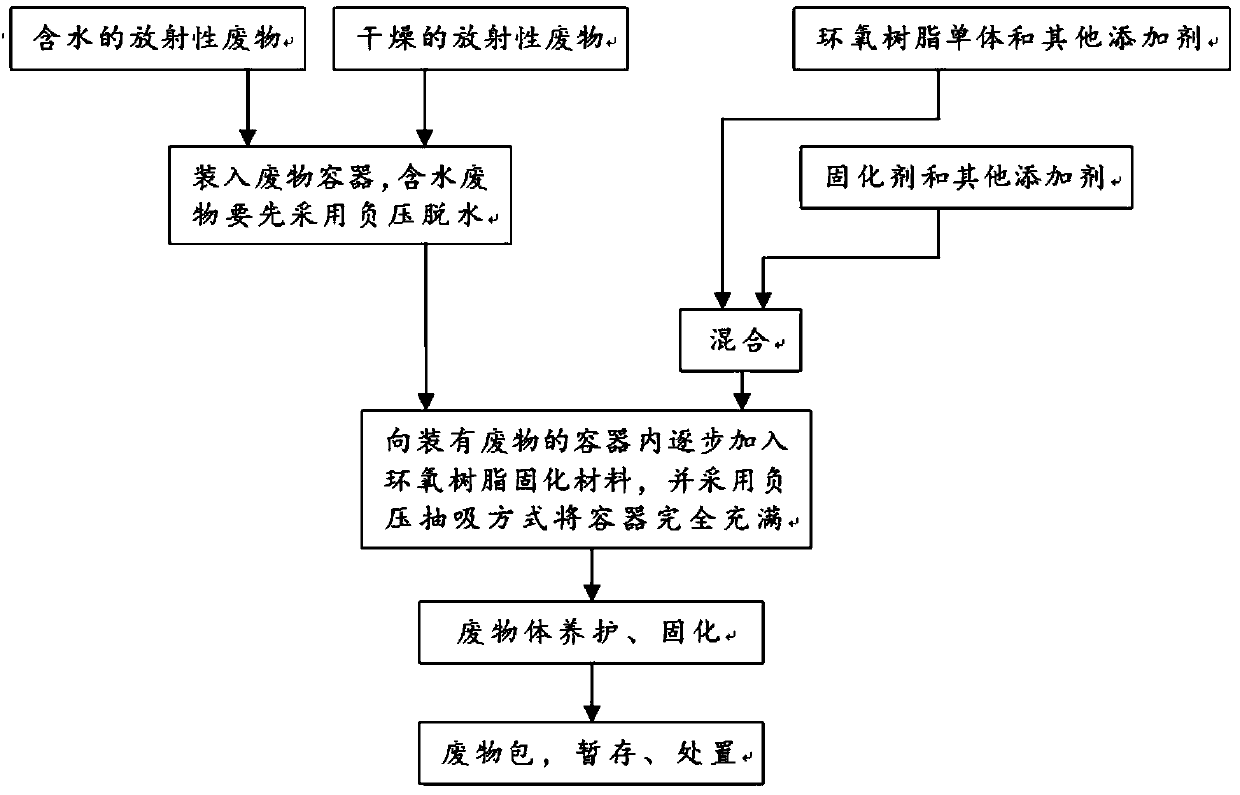

[0056] like figure 2 As shown, the solidification method provided in this embodiment is suitable for processing materials with larger particle size, such as waste filter media such as drained granular activated carbon or zeolite, and the difference from the solidification method in Example 1 is:

[0057] (1) Select epoxy resin curing material

[0058] In the step (2) of embodiment 1, according to the characteristics of radioactive waste, this embodiment selects the E-51 (EP01441 310) epoxy resin monomer with better fluidity, and the curing agent adopts T-31 epoxy curing agent , the mass ratio of the two is 5:1, and a diluent of 10-20% epoxy resin monomer mass is added to improve the fluidity of the epoxy resin cured material.

[0059] (2) Mixing of curing material of epoxy resin and radioactive waste

[0060] In the step (4) of embodiment 1, the mixing of epoxy resin cured material and radioactive waste adopts negative pressure suction mode to carry out (see figure 2 ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com