Multi-mode control method of active clamp fly-back converter

A flyback converter and control method technology, applied in control/regulation systems, conversion of DC power input to DC power output, instruments, etc., can solve the problem of low light-load efficiency, poor electromagnetic interference characteristics, and large primary peak current. and other problems, to achieve the effect of improving light load efficiency, avoiding audio noise, and small circulating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

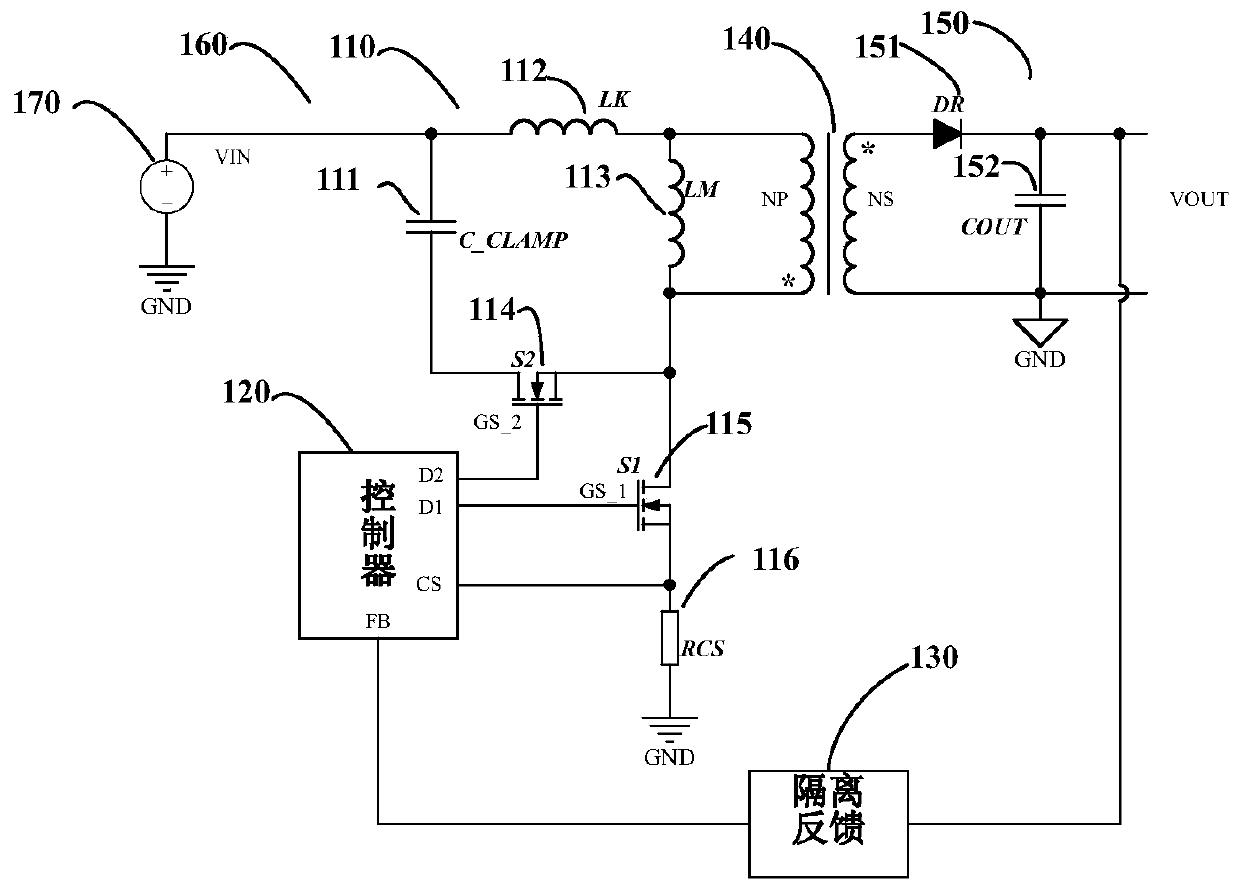

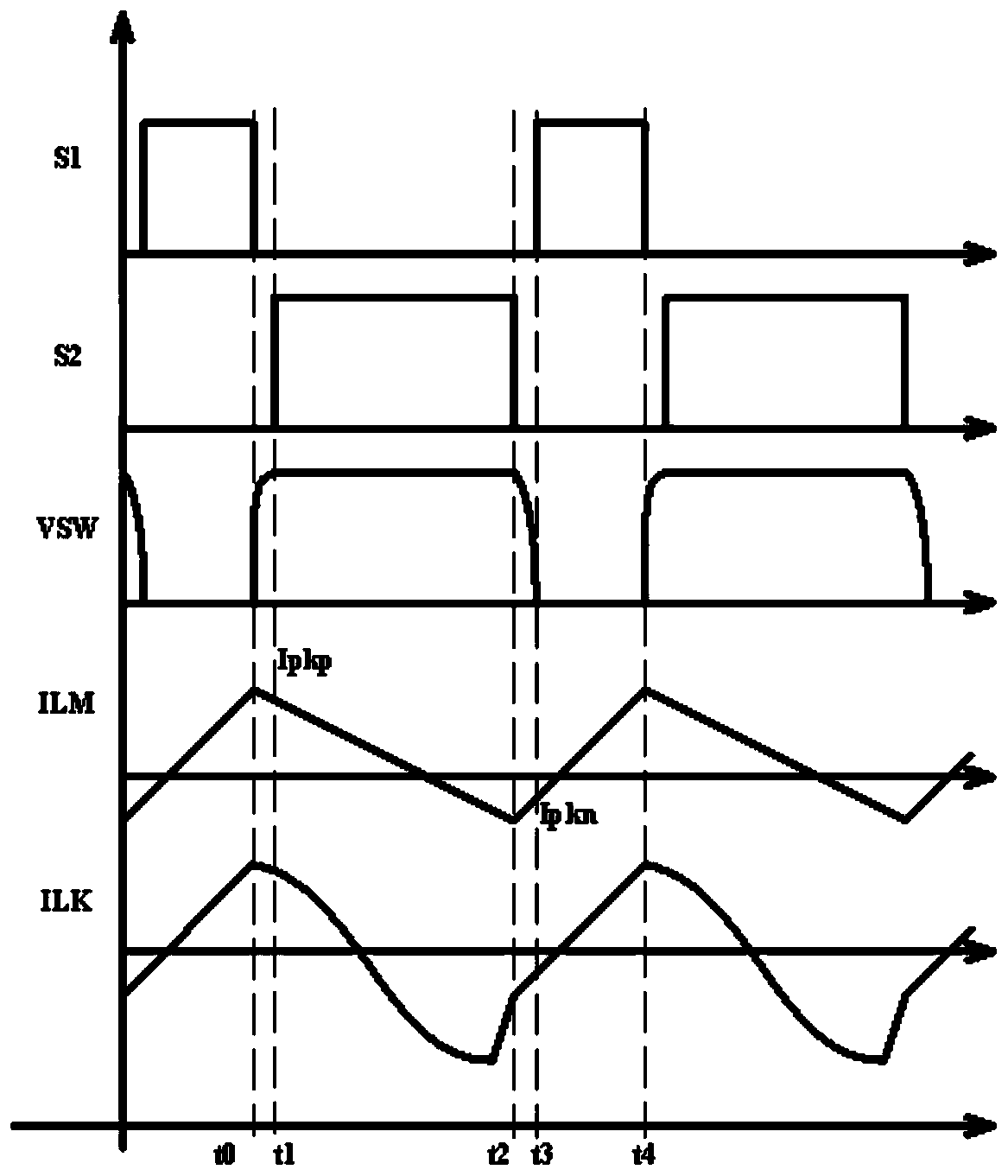

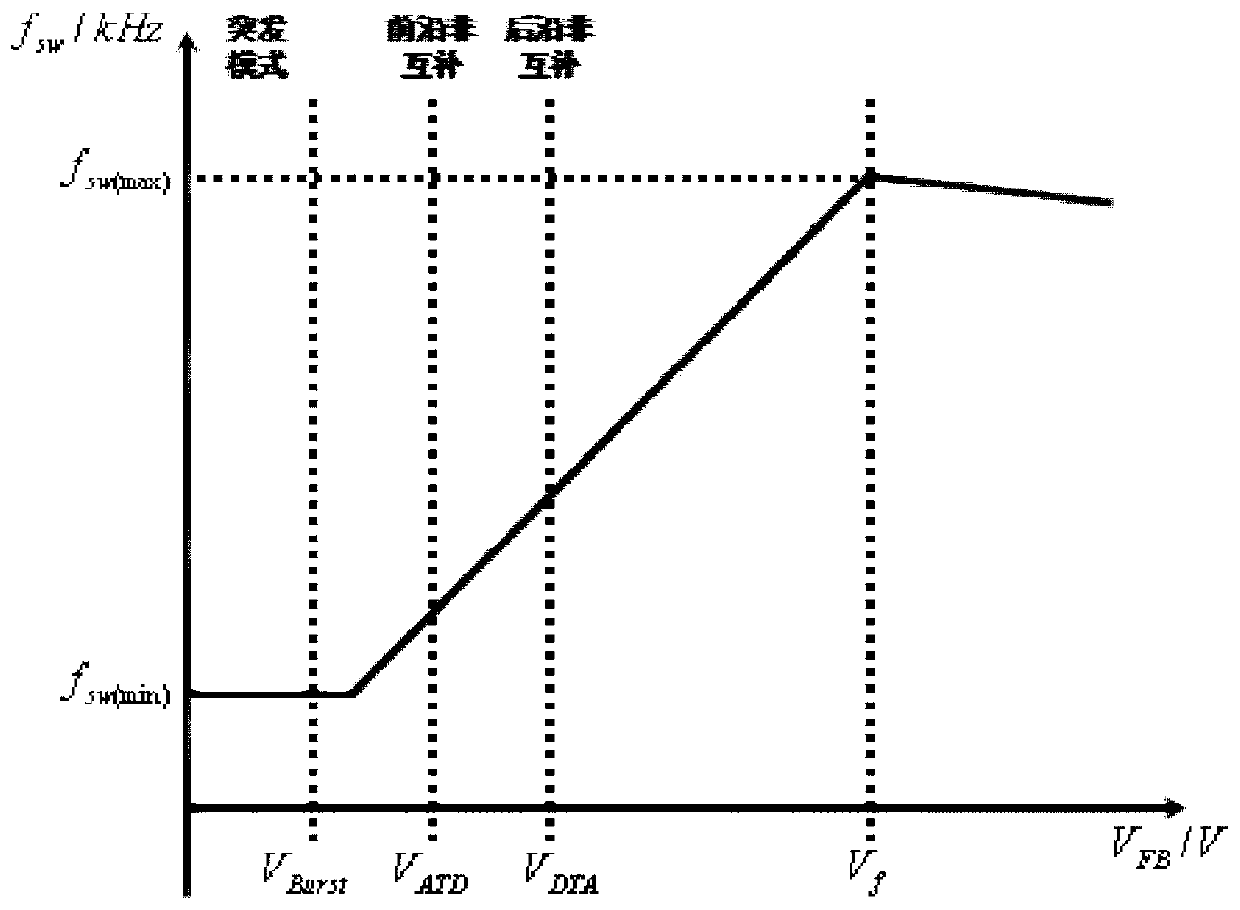

[0036] In one embodiment, a multi-mode flyback power supply includes an active clamp flyback converter and a controller. The active clamp flyback converter is used to adjust the input voltage and output the desired voltage. The active clamp flyback converter includes the main switch tube that controls the current of the primary winding of the flyback transformer, and the primary side of the flyback transformer The clamp switch tube for clamping the node voltage. The controller generates control signals for controlling the main switch and the clamp switch by detecting the FB voltage. The multi-mode flyback power supply can operate in trailing edge non-complementary mode, leading edge non-complementary mode and leading edge non-complementary burst mode (Burst mode ) These existing patterns combine to drive work. Among them, the switching frequency of the trailing edge non-complementary mode and the leading edge non-complementary mode changes with the change of the FB voltage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com