A kind of composite nanofiber online micro solid phase extraction column and preparation method thereof

A technology of composite nanofiber and solid phase extraction column, which is applied in the direction of separation method, fiber treatment, fiber type, etc., can solve the problems of limiting the development and application of micro solid phase extraction technology, limited types of solid phase adsorbents, poor extraction selectivity, etc. , to achieve the effect of strong anti-matrix interference, low cost and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

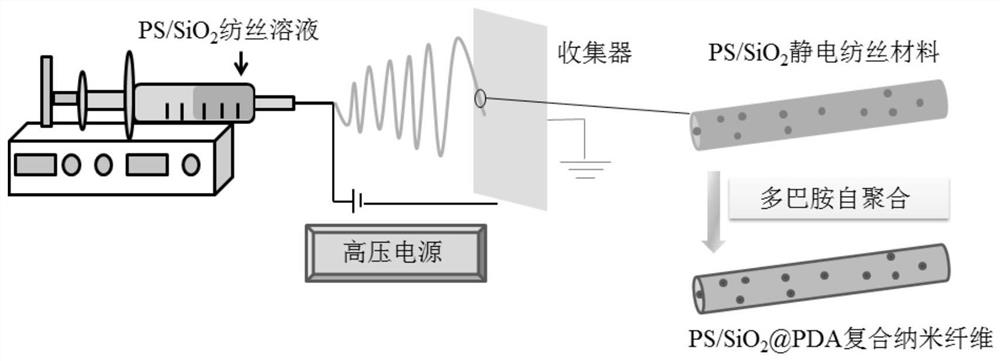

[0032] Example 1 PS / SiO 2 Preparation of @PDA Composite Nanofiber Online Micro Solid Phase Extraction Column Device

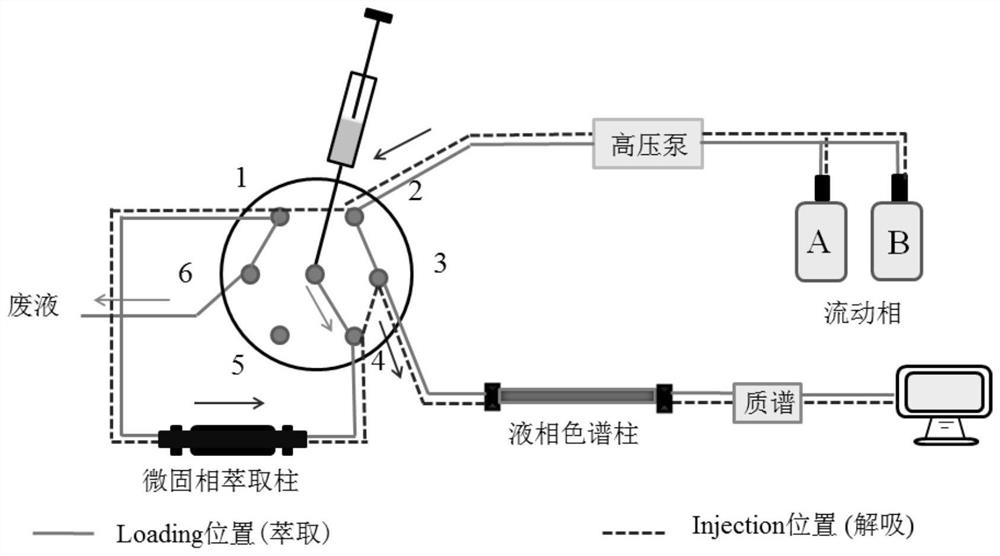

[0033] The present invention prepares PS / SiO by electrospinning technology 2 spinning material, and then prepare the PS / SiO by self-polymerization of dopamine 2 @PDA online micro solid phase extraction column, the preparation process is as follows figure 1 with figure 2 , including the following steps:

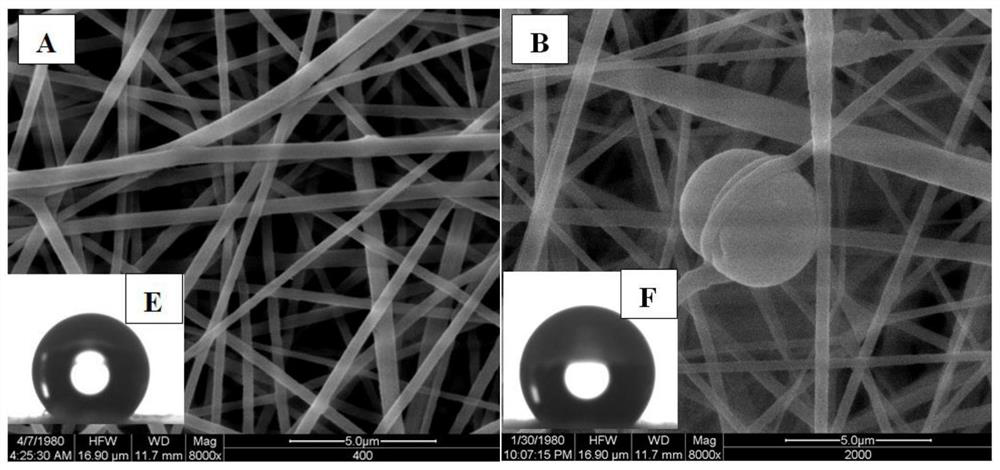

[0034] (1)PS / SiO2 2 Preparation of nanofibers: 20 mg of silica (SiO 2 ) particles were added to 10 milliliters of N,N-dimethylformamide solvent (DMF), and ultrasonically dispersed for 1 hour to obtain a dispersion solution; then, 1.5 grams of polystyrene (PS) was added to the dispersion solution, and the Stir the mixed solution for 48 hours to obtain a uniform electrospinning solution; then, transfer the viscous electrospinning solution to a 50 ml plastic syringe and fix it on a constant-flow syringe pump. The nozzle of the syringe is a stainless steel t...

Embodiment 2

[0040] Example 2 PS / SiO 2 Investigation on the Service Life of @PDA Composite Nanofiber Online Micro Solid Phase Extraction Column

[0041] Measure the PS / SiO that the embodiment of the present invention 1 makes 2 Extraction lifetime of hydroxylated polycyclic aromatic hydrocarbons (1-hydroxypyrene, 2-naphthol and 3-hydroxyphenanthrene) with @PDA composite nanofiber online micro solid-phase extraction column. The PS / SiO that the embodiment of the present invention 1 makes 2 The @PDA composite nanofiber online micro-solid phase extraction column continuously carried out the extraction and enrichment experiments of hydroxylated polycyclic aromatic hydrocarbons (1-hydroxypyrene, 2-naphthol and 3-hydroxyphenanthrene). , 52 times and 70 times) to analyze and compare the peak areas of the three target substances, so as to investigate the service life of the online solid phase extraction column pair.

[0042] The adsorbent PS / SiO 2 The amount of @PDA composite nanofiber is 4 mg, ...

Embodiment 3

[0044] Example 3 PS / SiO 2 @PDA composite nanofiber online micro solid phase extraction column and homemade PS / SiO 2 Comparison of the Enrichment Capabilities of Hydroxylated PAHs by On-line Micro Solid Phase Extraction Columns for Spinning Materials

[0045] Measure the PS / SiO that the embodiment of the present invention 1 makes 2 @PDA composite nanofiber online micro solid phase extraction column and homemade PS / SiO 2 The enrichment ability of the spinning material online micro-solid phase extraction column to hydroxylated polycyclic aromatic hydrocarbons (1-hydroxypyrene, 2-naphthol and 3-hydroxyphenanthrene): the PS / SiO prepared in Example 1 of the present invention 2 @PDA composite nanofiber online micro solid phase extraction column and homemade PS / SiO 2 Spinning material on-line micro-solid phase extraction column, when in the Loading position, extract 2 ml of 1-hydroxypyrene (1-hydroxypyrene), 2-naphthol (2-naphthol) and 3-hydroxyphenanthrene (3-hydroxyphenanthrene) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com