Computer display bracket assembly system with ring-shaped four-station layout and assembly method

A display bracket and assembly system technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems that it is difficult to ensure that the metal parts and accessories are completely installed in the base, the assembly failure rate is high, and it consumes a lot of manpower. , to achieve the effects of controllable production conditions, high product consistency and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

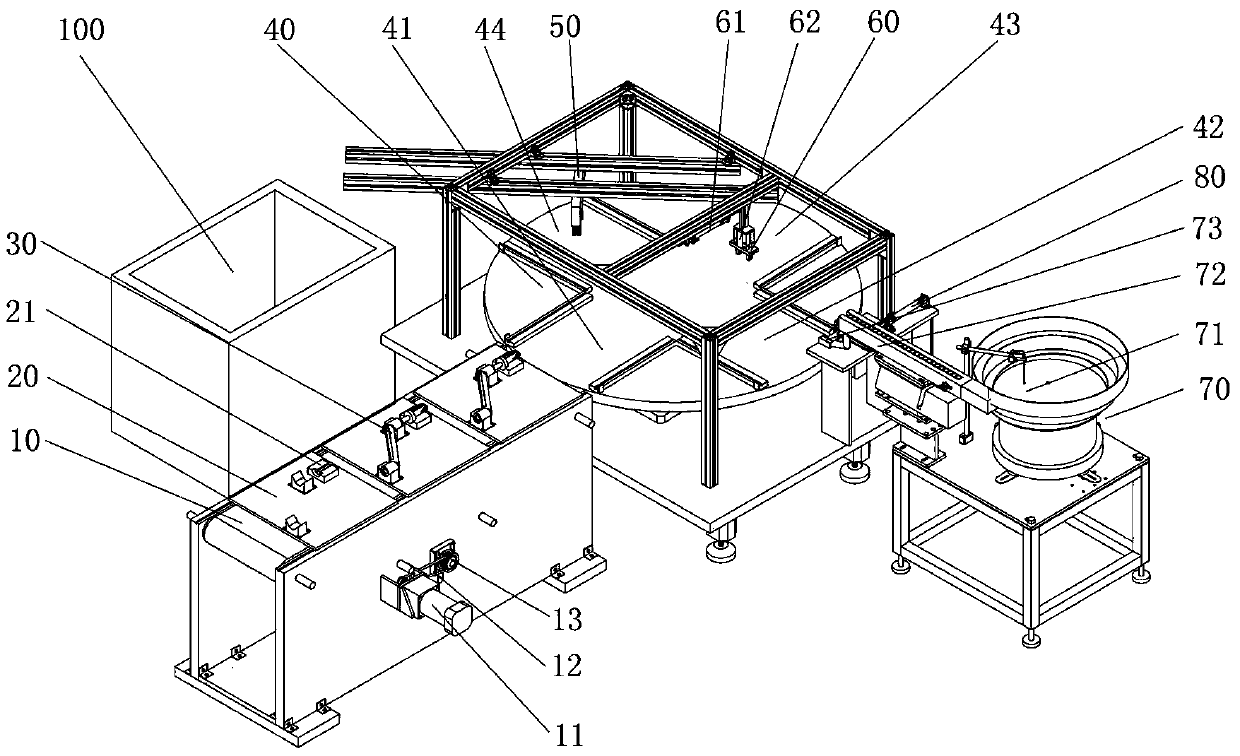

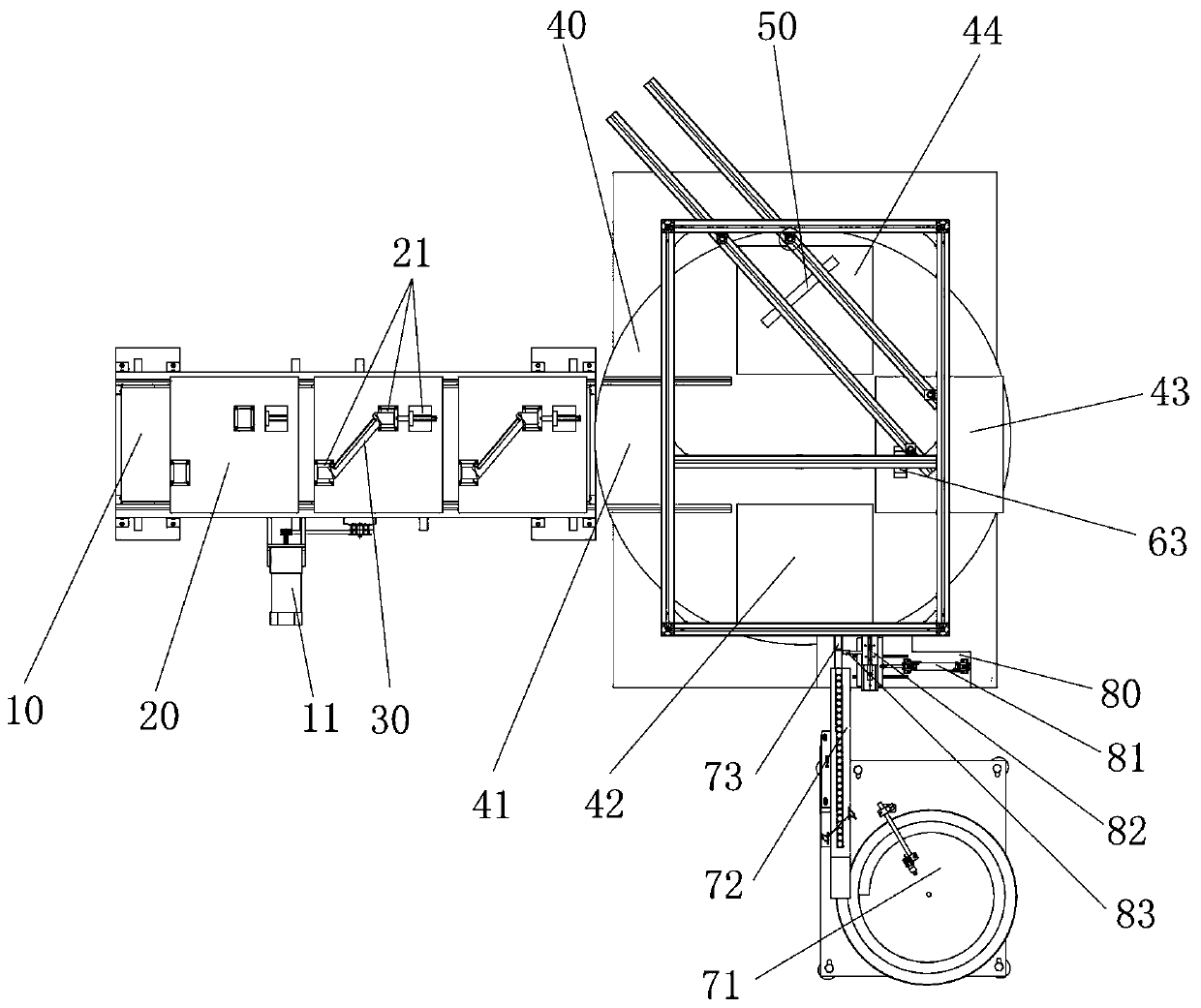

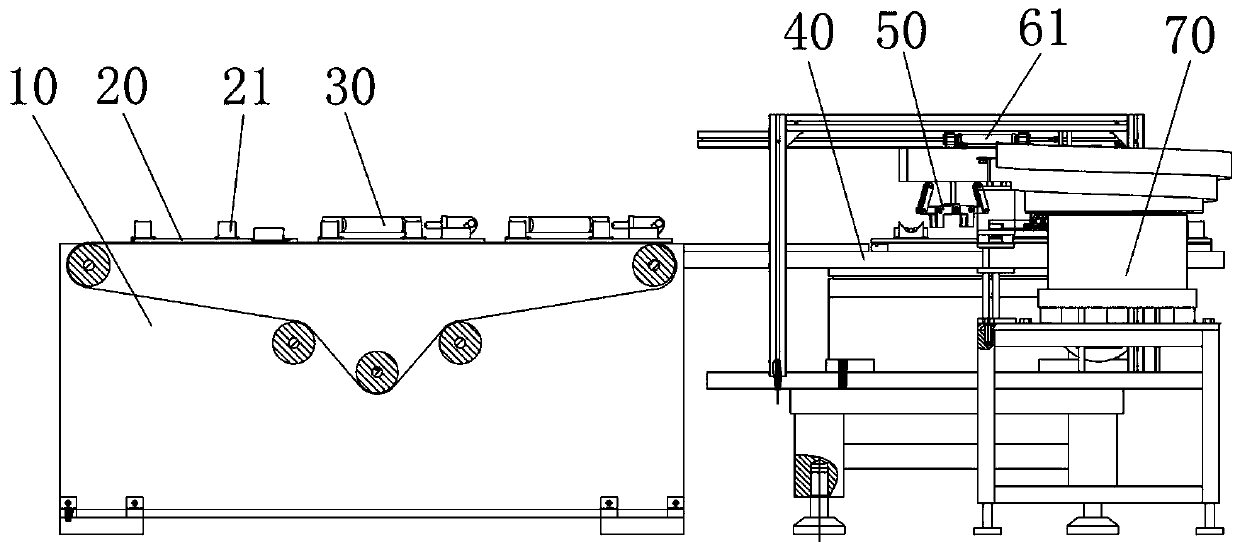

[0034] Such as Figures 1 to 7 As shown, a computer monitor stand assembly system with a ring-shaped four-station layout includes a transmission device 10 and a transportation board 20 located on the transmission device 10, and the transportation board 20 is fixedly installed with a tooling 21 for placing computer bracket parts 30 , the conveying end of the transmission device 10 is provided with a turntable 40 that can rotate intermittently, and the turntable 40 is sequentially arranged with a base material loading station 41, an auxiliary part feeding station 42, and a component fastening station 43 along the circumferential direction. and the unloading station 44, the auxiliary parts feeding station 42 side is provided with an auxiliary parts feeding mechanism 70, and the output end of the auxiliary parts feeding mechanism 70 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com