Environment-friendly cement packing machine

A packaging machine and cement technology, which is applied in packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low production capacity and poor output effect of cement packaging machines, so as to improve filling efficiency, production capacity, time and The effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

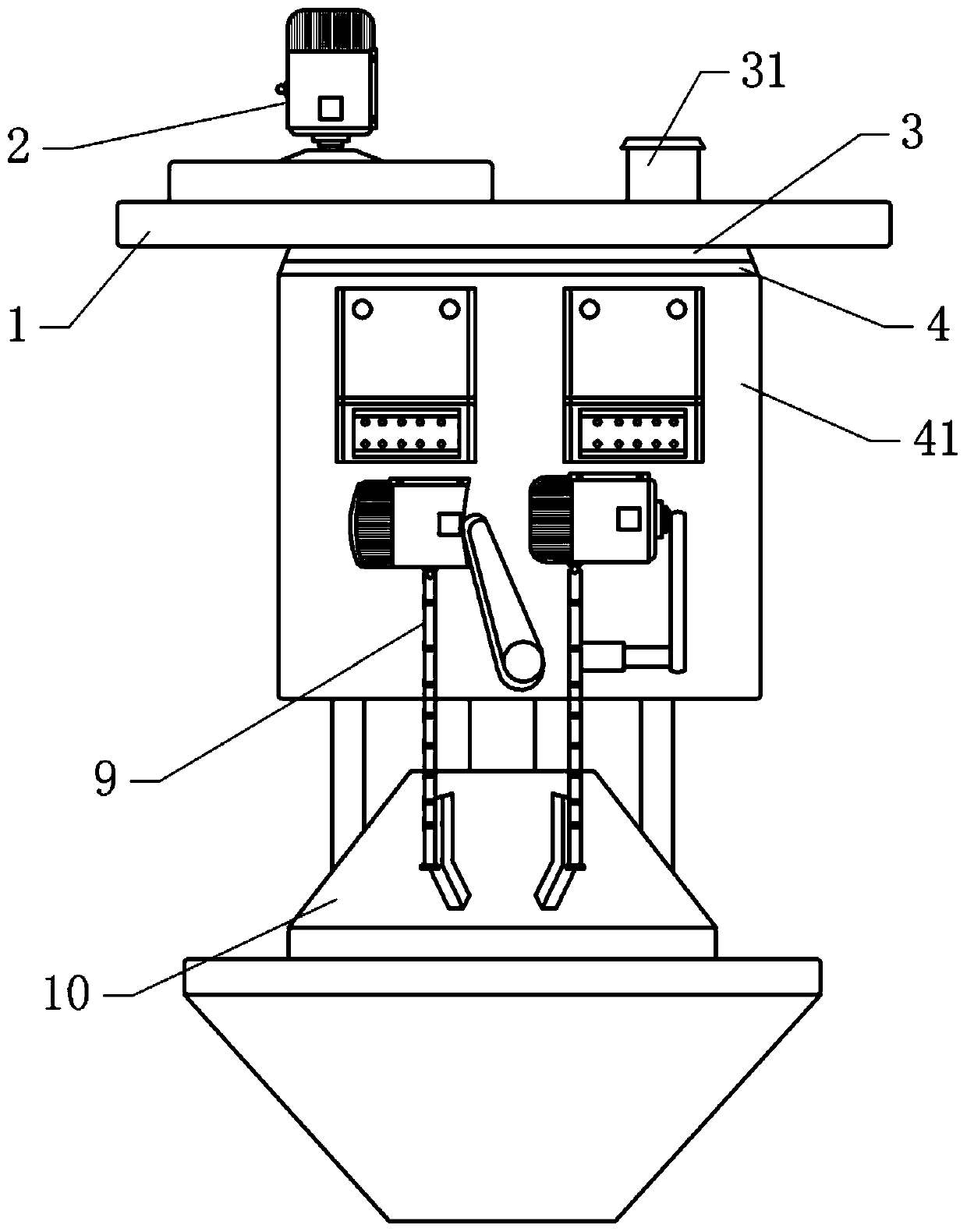

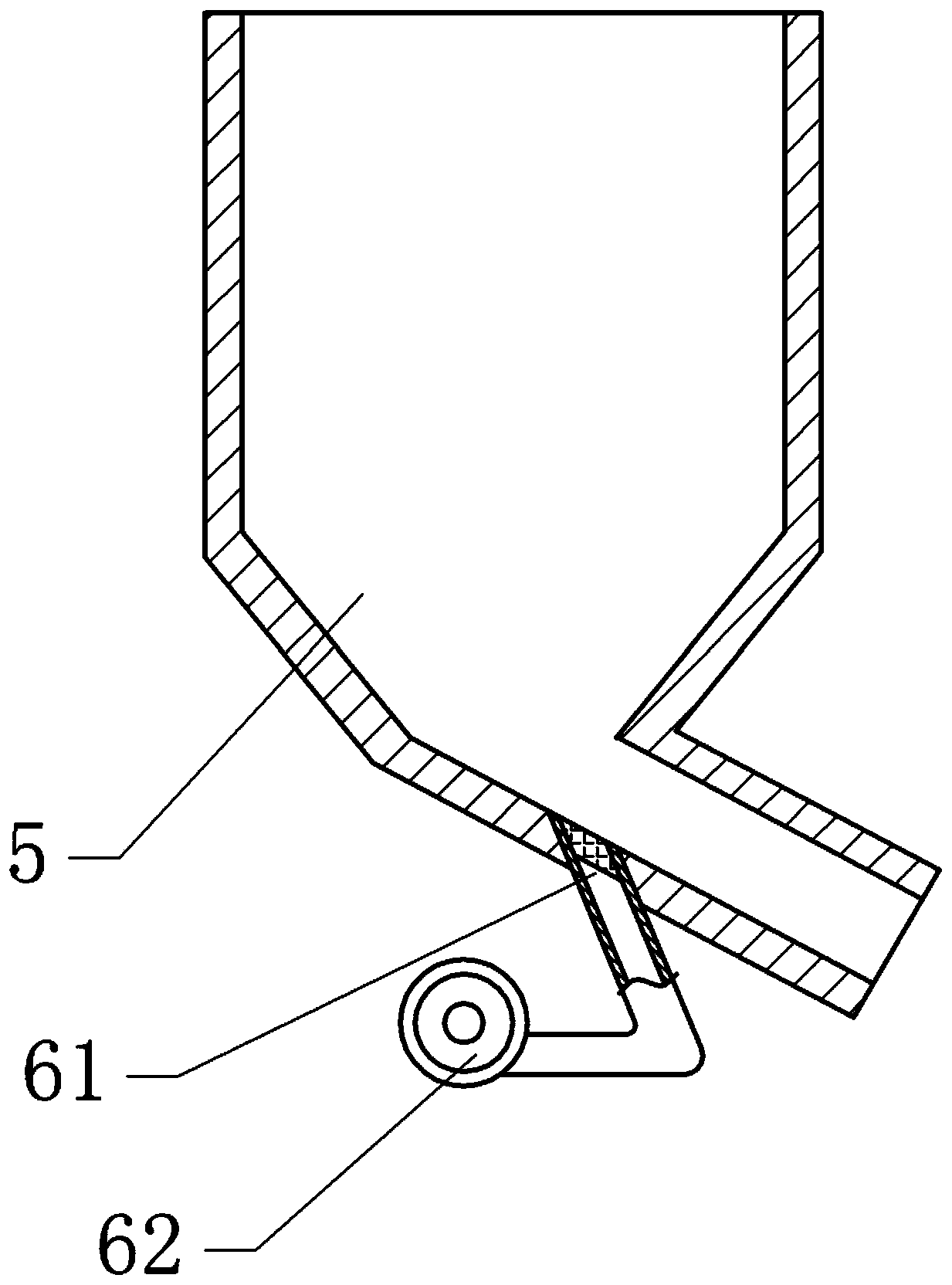

[0036] as attached figure 1 As shown, the environmentally friendly cement packaging machine is basically like the BHYW8D rotary cement packaging machine, including a suspension beam, a power system 2 is fixed above the suspension beam 1, and the power system 2 is a motor. Below the suspension beam hanger 1 are sequentially provided an upper cover 3 device, an upper rotary body, a filling system, a bagging mechanism, a switch smashing mechanism, a lower rotary body, and a microcomputer scale. There is a feeding cylinder 31, the upper rotating body includes a connecting plate 4 fixed with the upper cover 3, and a storage bin 41 communicating with the feeding cylinder 31 is fixed on the connecting plate 4; figure 2 As shown, the filling system includes an ash hopper 5 communicated with the storage bin 41 and a ventilation system 6 communicated with the ash outlet of the ash hopper 5; the bagging mechanism includes a bagging rack 9 fixed on the storage bin 41 , the ash outlet co...

Embodiment 2

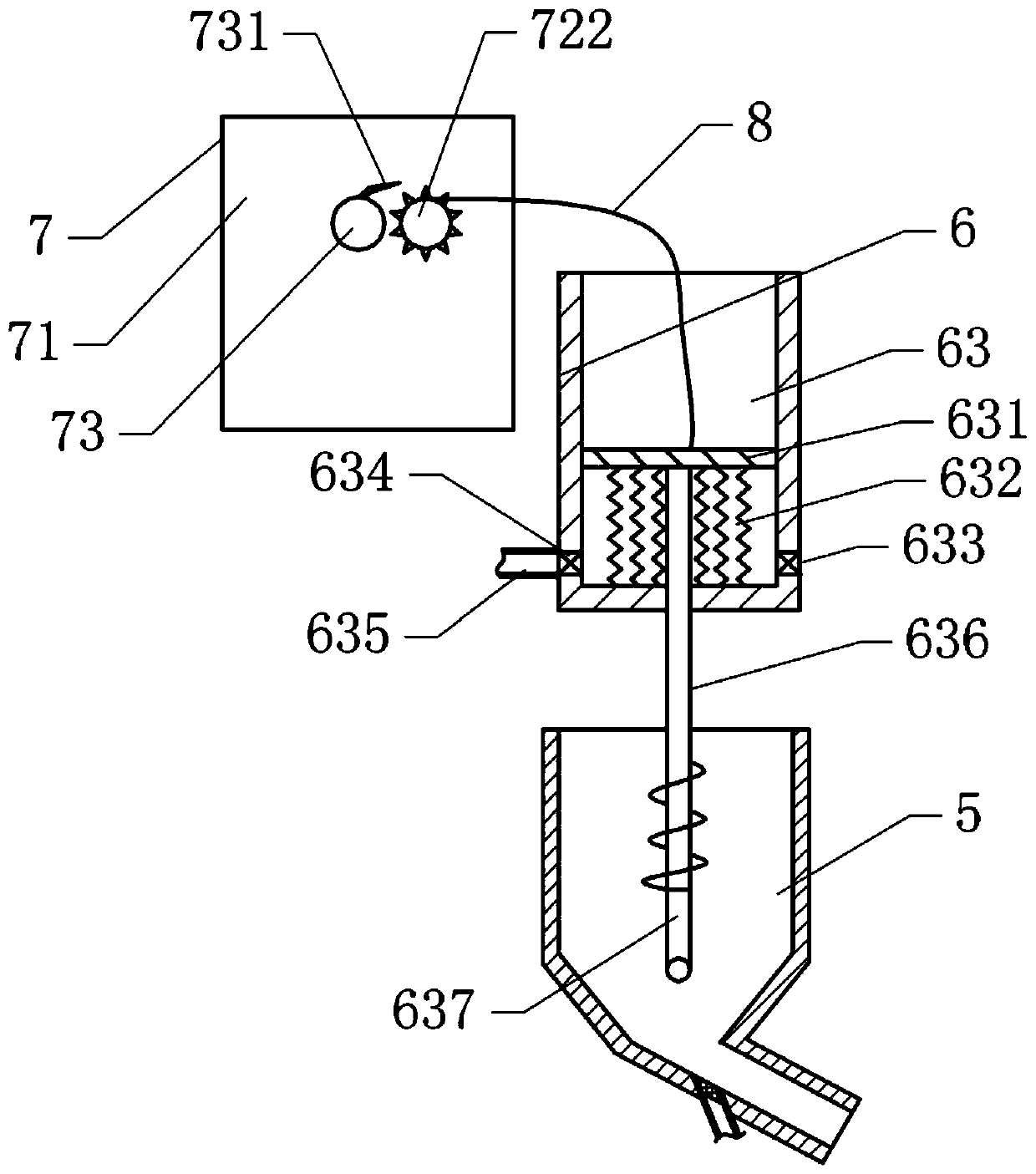

[0041] The difference between this embodiment and Embodiment 1 is that, as shown in the appendix image 3 As shown, the ventilation system 6 includes an air storage cylinder 63 fixed at the bottom of the storage bin 41, the bottom end of the air storage cylinder 63 is closed, a sliding plate 631 is vertically slidably connected in the air storage cylinder 63, and a sliding plate 631 is welded between the bottom of the sliding plate 631 and the bottom of the air storage cylinder 63. Spring 632. An air inlet 633 and an air outlet 634 are arranged on the side wall of the air storage cylinder 63 under the sliding plate. The air inlet 633 is provided with an air inlet one-way valve. When the sliding plate 631 moves up, the gas pressure at the lower part of the air storage cylinder 63 decreases. , the external air is sucked through the air inlet 633; the air outlet 634 is provided with an air outlet check valve, when the slide plate 631 moves down, the gas in the air storage cylin...

Embodiment 3

[0047] The only difference between this embodiment and Embodiment 2 is that, such as Figure 5 As shown, the driving mechanism 7 includes a pulley 74 and a rotating wheel 75 that are rotatably connected to the fixed plate 71. The pulley 8 is wound on the pulley 74 to form a fixed pulley 74 structure, and a ratchet rack 76 is fixed at one end of the pulley 8 away from the sliding plate 631. , the fixed plate 71 is provided with a vertical sliding groove, and the ratchet rack 76 is provided with a slider that cooperates with the sliding groove, so that the ratchet rack 76 can slide vertically along the sliding groove, and the rotating wheel 75 is provided with a 1 A pawl 731 that cooperates with the ratchet rack 76 .

[0048] The specific use process is as follows:

[0049] The rotating wheel 75 rotates, so that the pawl 731 intermittently cooperates with the ratchet rack 76, so that the ratchet rack 76 can drive one end of the pull rope 8 to move down, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com