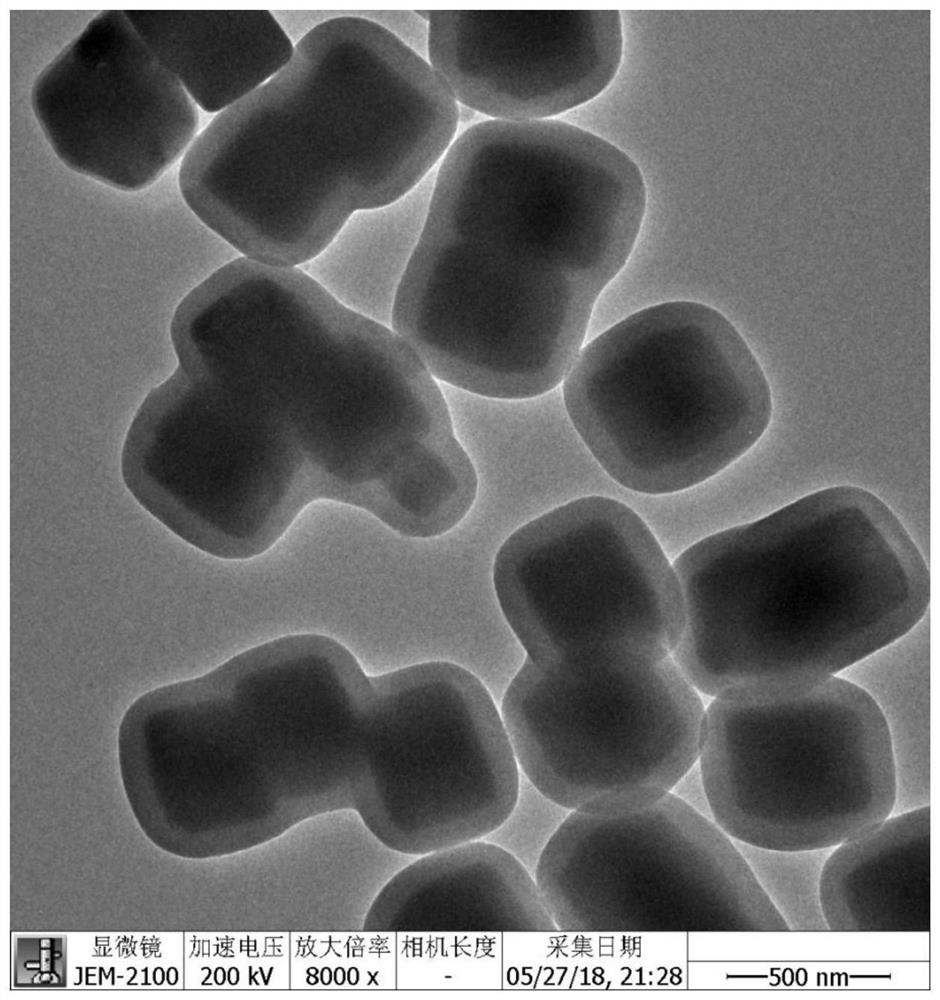

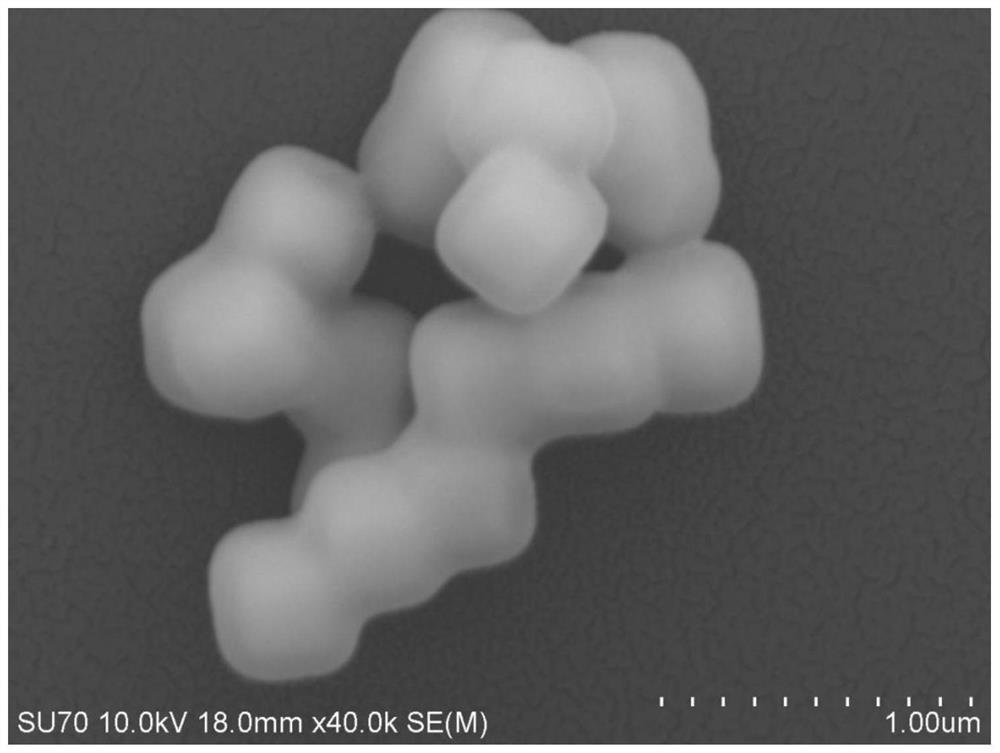

Preparation method of borate polymer @ cuprous oxide flame-retardant nanoparticles with core-shell structure

A core-shell structure, nanoparticle technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve problems such as weakening the flame retardant effect, achieve low price, good economy, and overcome changes. Effects of Sexual Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve 415mg 2,4,6-tris(N,4'-aminophenyl)-1,3,5-triazine, 648mg DOPO and 450mg 4-formylphenylboronic acid in 100ml methanol, avoid light Stir overnight to obtain a nitrogen-containing three-arm phenylboronic acid solution;

[0033] (2) Dissolve 198mg of 4,4-diaminodiphenylmethane, 432mg of DOPO and 276mg of 3,4-dihydroxybenzaldehyde in 100ml of methanol, and stir overnight in the dark to obtain a nitrogen-containing two-arm catechol solution;

[0034] (3) Add 400mg of cuprous oxide to 1L of methanol, and sonicate for 0.5h to obtain a methanol dispersion of cuprous oxide with a concentration of 0.4mg / ml;

[0035] (4) Add the above-mentioned cuprous oxide methanol dispersion into a reaction vessel, add 57ml of the above-mentioned nitrogen-containing two-arm catechol solution dropwise, and ultrasonically disperse it for 30 minutes;

[0036] (5) Dilute the above-mentioned nitrogen-containing three-arm phenylboronic acid solution containing an equimolar ratio to multi...

Embodiment 2

[0044] The preparation of nitrogen-containing three-arm phenylboronic acid solution and nitrogen-containing two-arm catechol solution is the same as the steps (1) to (2) of Example 1;

[0045] (3) Add 2 g of cuprous oxide to 2L of methanol, and ultrasonicate for 1 hour to obtain a methanol dispersion of cuprous oxide with a concentration of 1 mg / ml;

[0046] (4) Add the above-mentioned cuprous oxide methanol dispersion into the reaction vessel, add 22.8ml of the above-mentioned two-arm catechol solution containing phosphorus and nitrogen dropwise, and ultrasonically 0.5h to make it uniformly dispersed;

[0047](5) Dilute the above-mentioned nitrogen-containing three-arm phenylboronic acid solution containing equimolar ratio to multi-arm catechol to 1 mg / ml, slowly add dropwise to the material obtained in step (4), and react at room temperature for 72 hours after the dropwise addition .

[0048] (6) After the reaction is completed, the precipitate is obtained by centrifugation...

Embodiment 3

[0051] The involved multi-arm phenylboronic acid and catechol monomers containing elements such as phosphorus and nitrogen are prepared as follows:

[0052] (1) Dissolve 783mg hexa(4-aminophenoxy)cyclotriphosphazene, 1296mg DOPO and 900mg 4-formylphenylboronic acid in 10ml methanol, and stir overnight in the dark to obtain a phosphorus-nitrogen-containing six-arm phenylboronic acid solution ;

[0053] (2) Dissolve 792mg of 4,4'-diaminodiphenylmethane, 1728mg of DOPO and 1104mg of 3,4-dihydroxybenzaldehyde in 20ml of methanol, and stir overnight in the dark to obtain a nitrogen-containing two-arm catechol solution ;

[0054] (3) Add 1000 mg of cuprous oxide to 100 ml of methanol, and sonicate for 0.5 h to obtain a methanol dispersion of cuprous oxide with a concentration of 1 mg / ml;

[0055] (4) Add the above-mentioned cuprous oxide methanol dispersion into the reaction vessel, add 190.5ml of the above-mentioned two-arm catechol solution containing phosphorus and nitrogen dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com