Device for removing CO2 from European smelting furnace gas

A technology for coal gas and shaft furnaces, which is applied in the direction of combustible gas purification/transformation, combustible gas purification, and reduction of gas emission, etc. , the effect of solving gas shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

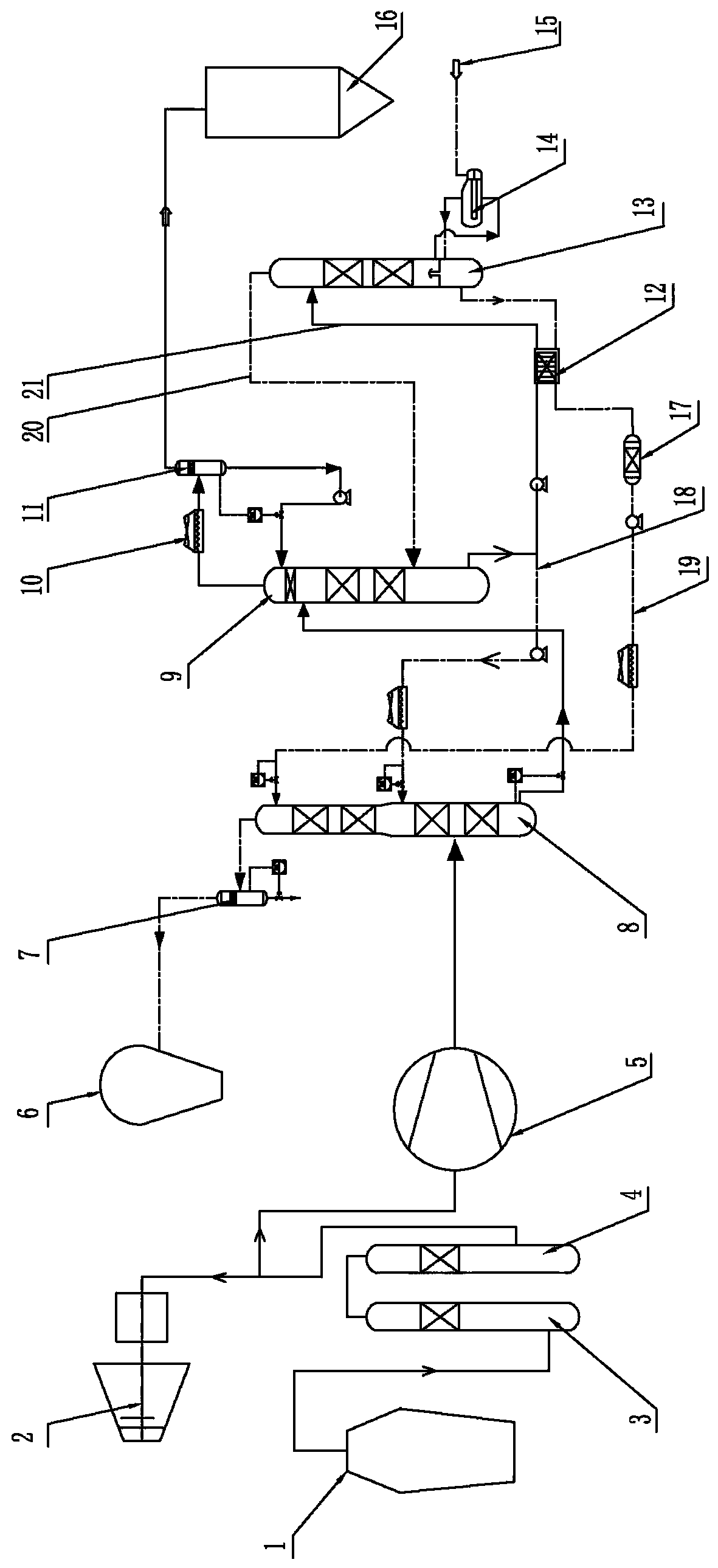

[0010] A Ouyeel Furnace Gas Removal of CO 2 devices such as figure 1 As shown, it includes a shaft furnace 1 with a top gas output pipe, a washing and cooling tower 3, a water-gas separator 4, a high-pressure gas residual pressure turbine power generation device TRT 1, a compressor 5, a gasifier 6, an absorption tower 8, and a normal Decomposition tower 9, stripper 13, cooler, reboiler 14, separator and coal injection device 16, the top gas output pipe of shaft furnace 1 passes through washing cooling tower 3, water-gas separator 4 and described TRT successively 1 and the compressor 5 are connected, the gas output end of the compressor 5 is connected with the bottom of the absorption tower 8, and the top of the absorption tower 8 is connected with the gasification furnace 6 through a purified gas separator 7; the bottom of the absorption tower 8 is provided with Liquid outlet pipe, this liquid outlet pipe links to each other with the top of normal solution tower 9. The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com