A kind of composite material brake drum and preparation method thereof

A composite material, brake drum technology, applied in the direction of brake type, brake components, metal material coating process, etc. The problem is that the heat dissipation performance of the type brake is poor, and the effect of high rigidity, excellent thermal fatigue performance and reduced inertial resistance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

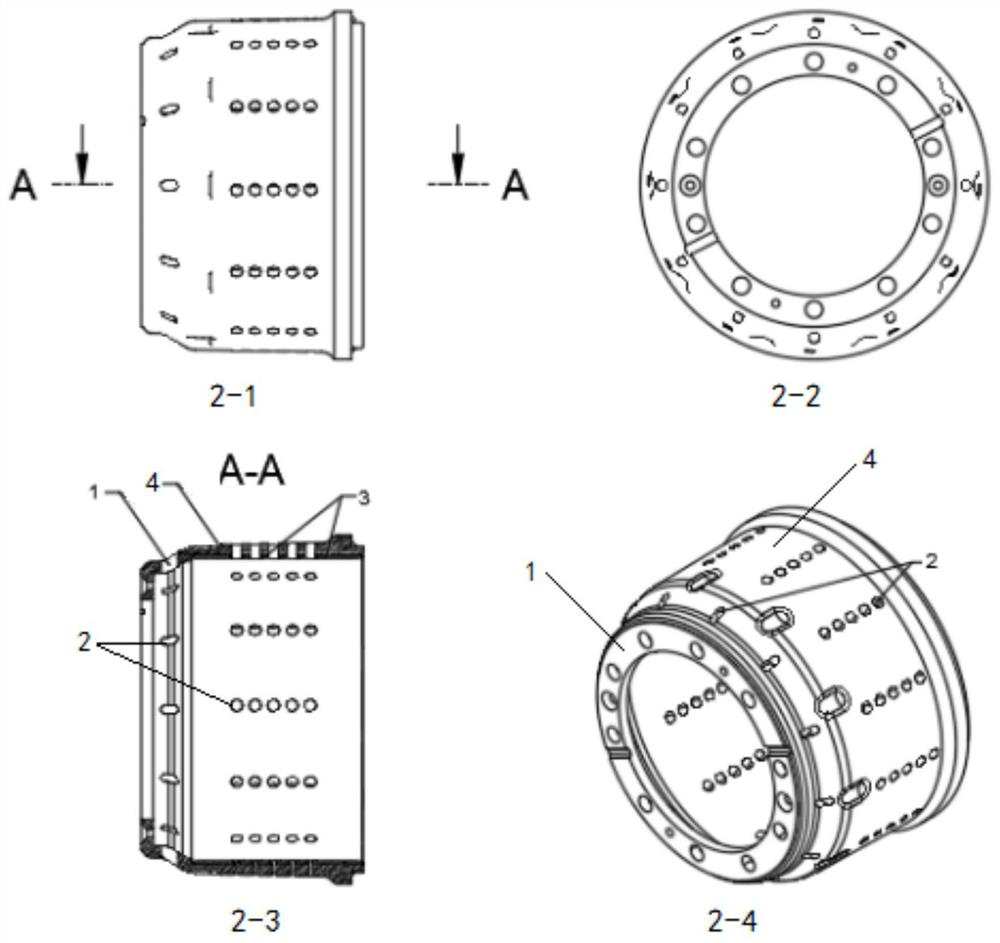

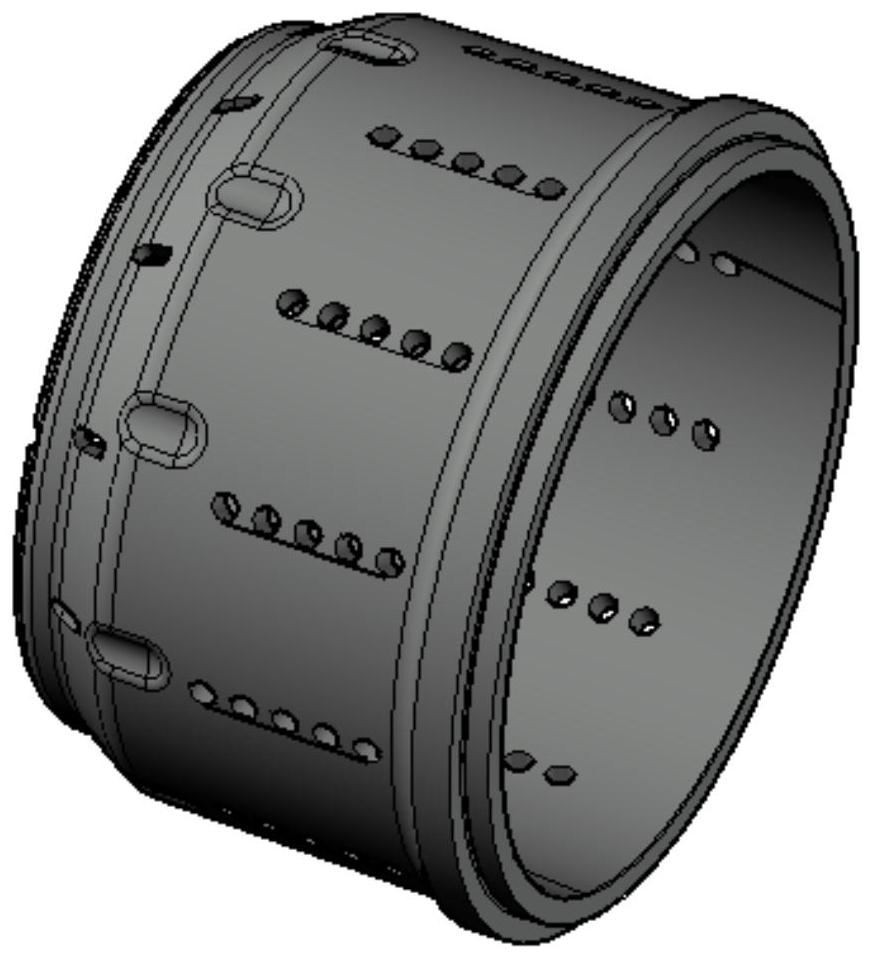

[0051] The composite material brake drum provided in this embodiment is as figure 2 and 3 As shown, the brake drum body includes a friction body 4 and a base 1. On the friction body 4, 12 groups of chip removal holes 2 are evenly distributed side by side. The number of each group of chip removal holes 2 is 6, and each group of chip removal holes 2 They are all parallel to the central axis of the composite material brake drum, and the wall thickness of the friction body is 16mm.

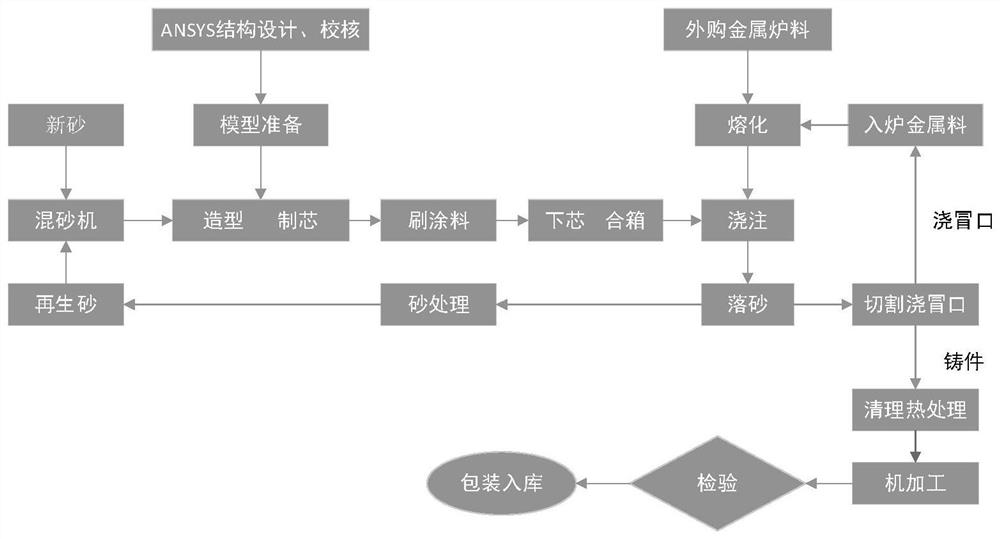

[0052] The production process of composite material brake drum is as follows: figure 1 shown.

[0053] Using ANSYS structure optimization and strength check, the core box and cavity model are designed.

[0054] Select the braking molding equipment to make the pouring cavity, and use the core shooter to make the sand core.

[0055] ZG35CrMoV alloy steel (strength ≥ 800MPa) is used as the base material of the brake drum.

[0056] The alloy steel is smelted in advance by using appropriate melting equ...

Embodiment 2

[0064] The production technological process of present embodiment composite material brake drum is as follows figure 1 shown.

[0065] Using ANSYS structure optimization and strength check, the core box and cavity model are designed.

[0066] Select the braking molding equipment to make the pouring cavity, and use the core shooter to make the sand core.

[0067] ZG35CrMoV alloy steel (strength ≥ 800MPa) is used as the base material of the brake drum.

[0068] The alloy steel is smelted in advance by using appropriate melting equipment, and the obtained alloy steel solution is used for standby.

[0069] Select a suitable carburizing agent for use, graphite powder 40wt%, ferrosilicon powder 18wt%, binder 2wt%, suspension stabilizer 4.5wt%, auxiliary agent 0.5wt% and ethanol 35wt%.

[0070] The above-mentioned carburizing agent is coated on the surface of the sand core (the surface of the sand core is in contact with the inner surface of the brake drum).

[0071] Using the gr...

Embodiment 3

[0076] The production technological process of present embodiment composite material brake drum is as follows figure 1 shown.

[0077] Using ANSYS structure optimization and strength check, the core box and cavity model are designed.

[0078] Select the braking molding equipment to make the pouring cavity, and use the core shooter to make the sand core (the surface of the sand core is in contact with the inner surface of the brake drum).

[0079] ZG35CrMoV alloy steel (strength ≥ 800MPa) is used as the base material of the brake drum.

[0080] The alloy steel is smelted in advance by using appropriate melting equipment, and the obtained alloy steel solution is used for standby.

[0081] Select a suitable carburizing agent for future use, graphite powder 45wt%, ferrosilicon powder 20wt%, binder 4wt%, suspension stabilizer 2wt%, auxiliary agent 0.5wt% and ethanol 28.5wt%.

[0082] The above-mentioned carburizing agent is coated on the surface of the sand core (the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com