Isolated integrated high-precision liquid level measuring equipment and liquid level measuring method

A liquid level measurement and isolation technology, which is applied in the direction of liquid/fluid solid measurement, measuring device, liquid level indicator for physical variable measurement, etc., can solve the problem of high power consumption measurement blind area of radar water level gauge, gas-mediated ultrasonic water level The measurement accuracy of the meter is affected by temperature and humidity, etc., to achieve the effect of isolated measurement, small overall structure, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

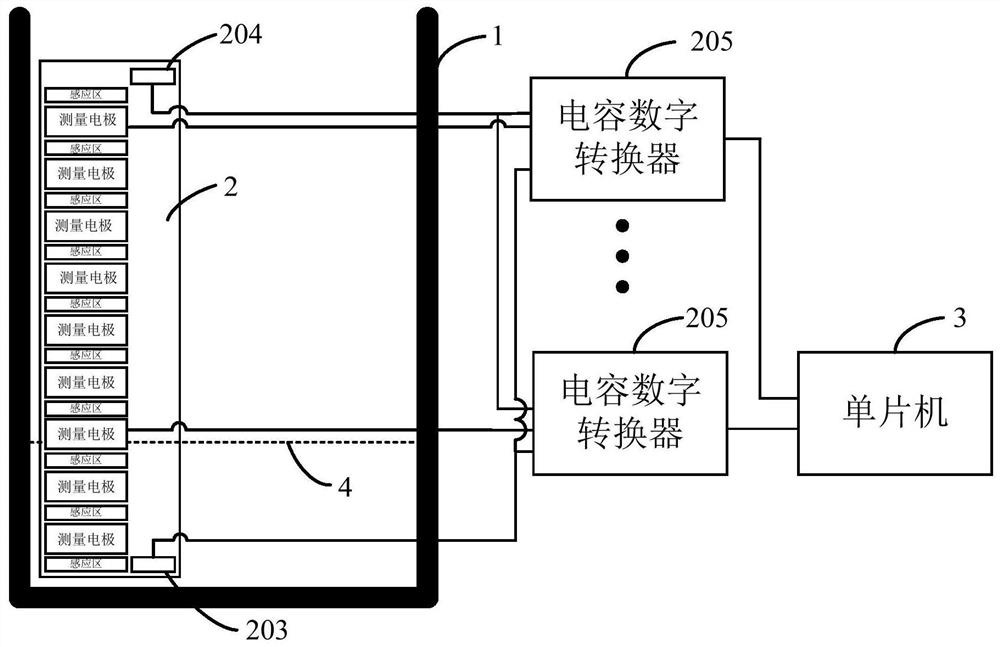

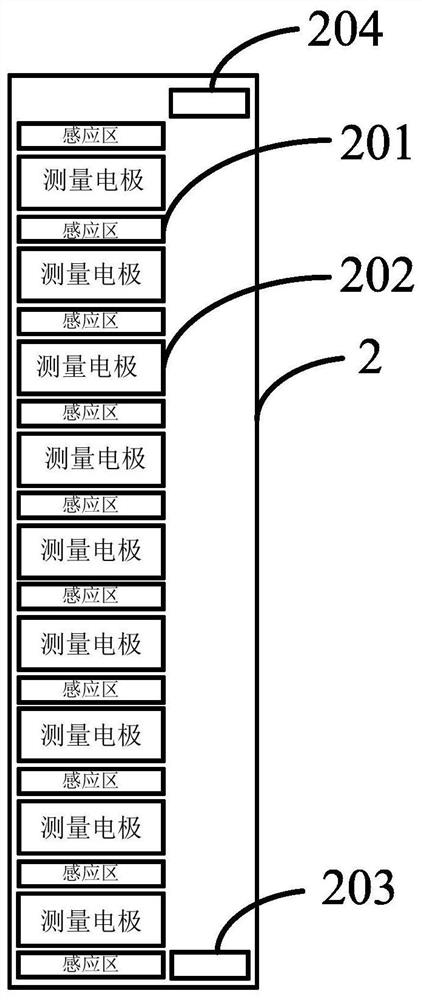

[0054] Such as figure 1 and figure 2 As shown, this embodiment provides an isolated integrated high-precision liquid level measuring device, which includes a housing 1 , a sensing panel 2 and a Microcontroller Unit (MCU for short) 3 .

[0055] The sensing panel 2 and the single-chip microcomputer 3 are arranged inside the casing 1, constituting the measurement module of the liquid level measuring equipment. The sensing panel 2 is attached to the inner side of the casing 1 and is not directly exposed, while the casing 1 is also integrated with a data transmission module and a power supply battery. The single chip microcomputer 3, the data transmission module and the power supply battery are arranged on a circuit board, and the data transmission module is a wireless network connection module. Through the data transmission module, the communication between the liquid level measurement equipment and the data server can be realized, and the liquid level measurement equipment can b...

Embodiment 2

[0080] The structure of the liquid level measuring device in this embodiment is the same as in Embodiment 1, but the liquid level measuring range of the liquid level measuring device is set to 200mm, that is, there are twenty sensing areas 201, and nineteen liquid level measuring electrodes 202, such as Figure 7 Shown; the serial numbers of the sensing area 201 are respectively k 1 , k 2 , k 3 ,...,k 20 , assuming that the current water depth is 115mm, the liquid level measurement process is as follows:

[0081] (1) Start the first-level measurement calculation.

[0082] (1.1) Search from bottom to top, read the state of the output of the sensing area, at this time the kth 1 The sensing area of the order to the kth 11 The induction area of the order is 0, the kth 12 The sensing area of the order to the kth 20 The induction area of each order is 1.

[0083] (1.2) According to the output state of the sensing area, it is judged that the current liquid level line ...

Embodiment 3

[0090] The structure of the liquid level measuring device in this embodiment is the same as in Embodiment 1, but the liquid level measuring range of the liquid level measuring device is set to 200mm, that is, there are twenty sensing areas 201, and nineteen liquid level measuring electrodes 202, such as Figure 8 Shown; the serial numbers of the sensing area 201 are respectively k 1 , k 2 , k 3 ,...,k 20 , assuming that the current water depth is 115mm, and the k-th 15 The surface of the casing corresponding to the sensing area of the first stage has impurities attached, and the liquid level measurement process is as follows:

[0091] (1) Start the first-level measurement calculation.

[0092] (1.1) Search from bottom to top, read the state of the output of the sensing area, at this time the kth 1 The sensing area of the order to the kth 11 The induction area of the order is 0, the kth 12 The sensing area of the order to the kth 14 The induction area of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com