Flat panel detector

A flat-panel detector and substrate technology, applied in semiconductor devices, electric solid-state devices, radiation control devices, etc., can solve problems such as abnormal image electrical signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] Embodiments of the present invention also provide a method for preparing a flat panel detector, such as Figure 9 shown, including:

[0074] S10 , forming a photodiode 11 on the substrate 10 .

[0075] S20, forming a transmissive conductive layer 20 and a signal line 19 connected to the photodiode 11 on the substrate 10 formed with the photodiode 11, wherein the orthographic projection of the transmissive conductive layer 20 on the substrate 10 is the same as that of the photodiode 11 on the substrate Orthographic overlap on 10.

[0076] In some embodiments, step S20 includes:

[0077] S201 , forming a signal line 19 connected to the photodiode 11 on the substrate 10 formed with the photodiode 11 .

[0078] S202 , forming a transmissive conductive layer 20 on the substrate 10 formed with the signal line 19 .

[0079] That is to say, after the photodiode 11 is formed, the signal line 19 is formed first, and then the transmissive conductive layer 20 is formed.

[008...

Embodiment 1

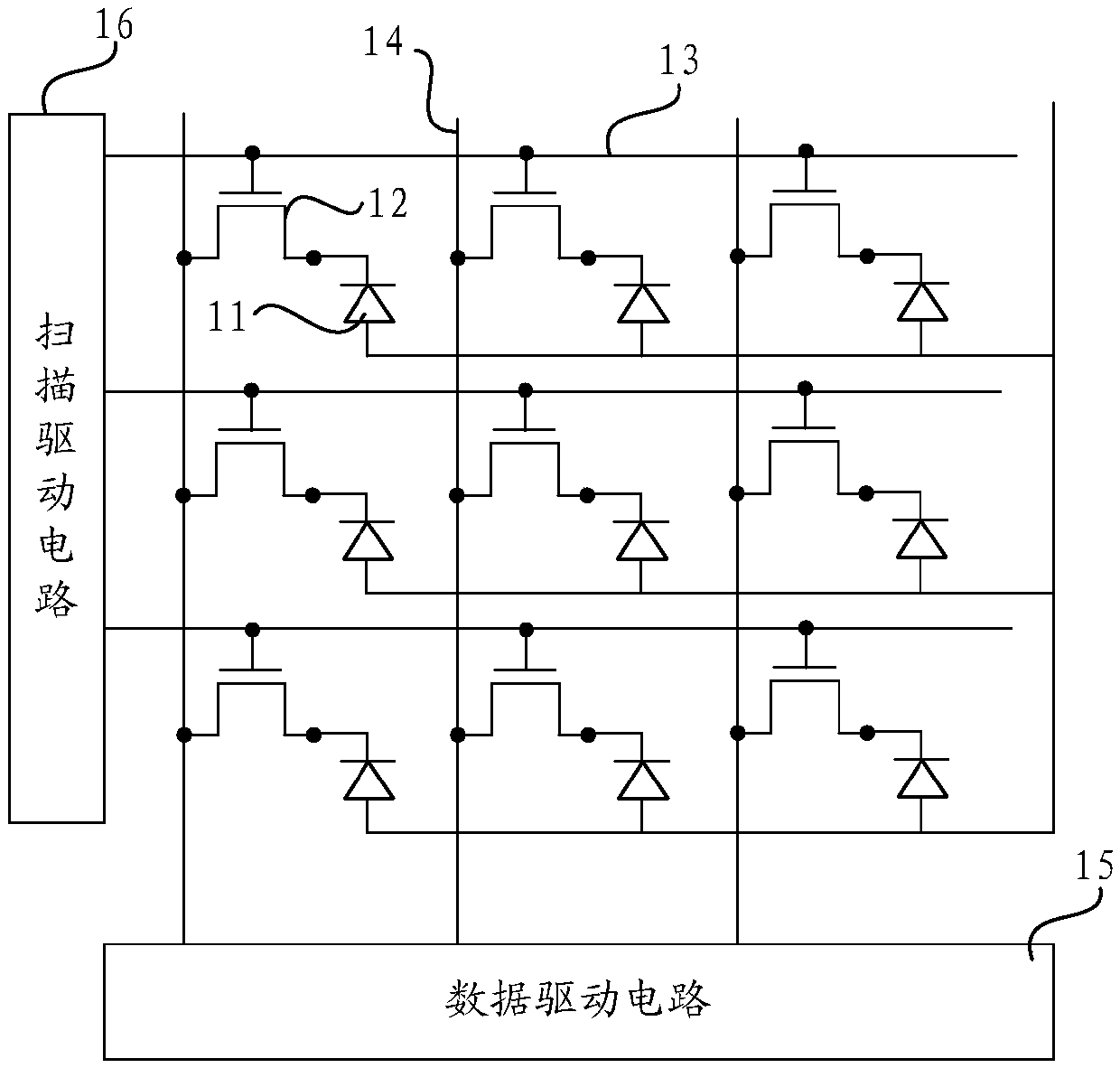

[0086] prepared as Figure 5 Flat panel detectors shown, including:

[0087] S100 , forming a thin film transistor 12 on a substrate 10 .

[0088] Exemplarily, step S100 includes:

[0089] S110 , forming a gate on the substrate 10 .

[0090] S120, forming a gate insulating layer on the substrate 10 on which the gate is formed.

[0091] S120, forming an active layer on the substrate 10 formed with the gate insulating layer.

[0092] S120, forming a source electrode and a drain electrode on the substrate 10 on which the active layer is formed.

[0093] S200 , forming a photodiode 11 on the substrate 10 on which the thin film transistor 12 is formed.

[0094] Exemplarily, step S200 includes:

[0095] S210 , forming an N-type semiconductor layer on the substrate 10 on which the thin film transistor 12 is formed.

[0096] S220, forming an intrinsic semiconductor layer on the substrate 10 formed with the N-type semiconductor layer.

[0097] S230, forming a P-type semiconduct...

Embodiment 2

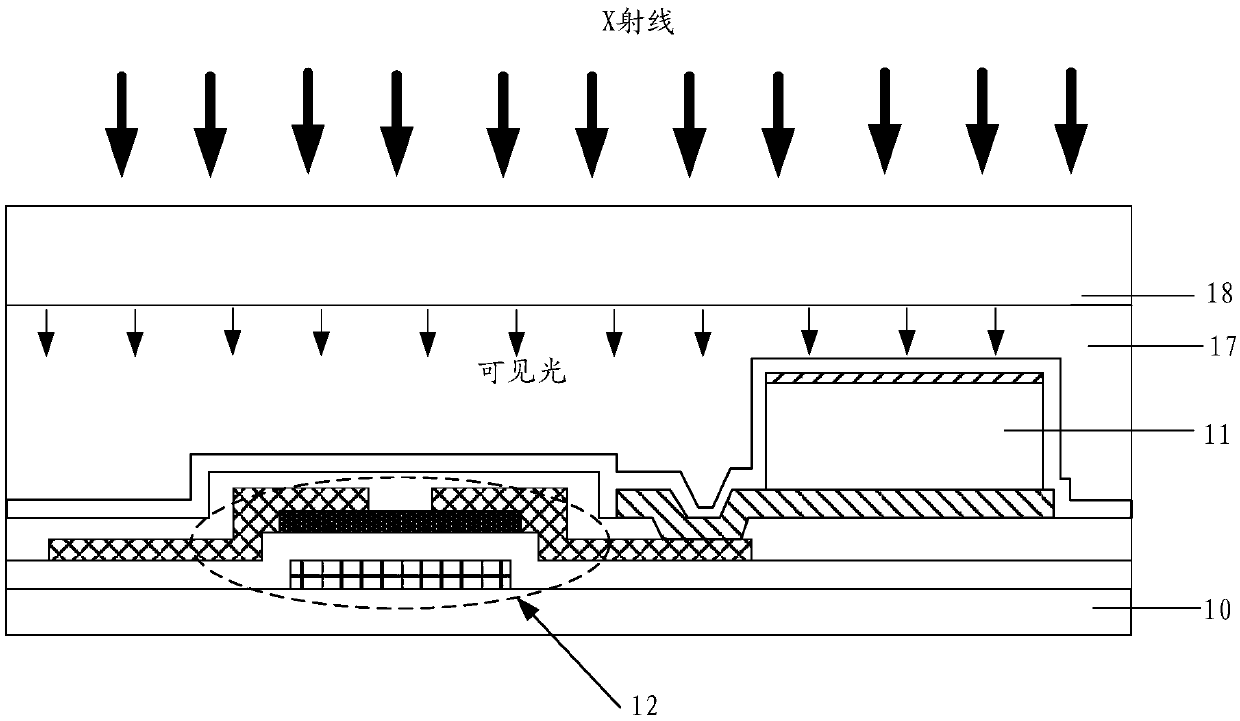

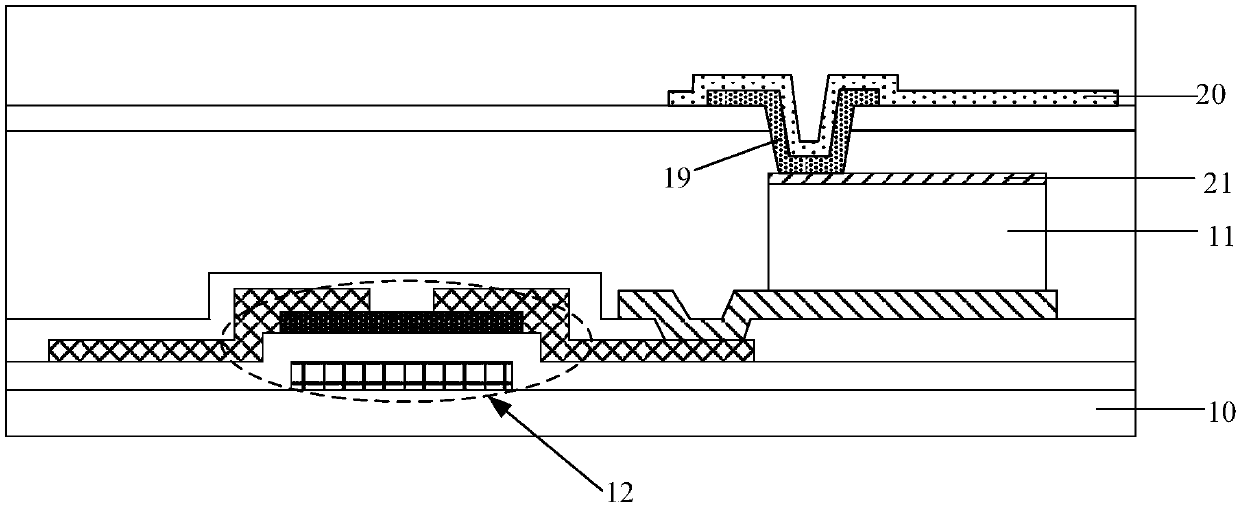

[0104] prepared as Figure 6 Flat panel detectors shown, including:

[0105] S100 , forming a thin film transistor 12 on a substrate 10 .

[0106] S200 , forming a photodiode 11 on the substrate 10 on which the thin film transistor 12 is formed.

[0107] S300 , forming a flat layer 17 on the substrate 10 on which the photodiode 11 is formed.

[0108] S400 , forming a signal line 19 on the substrate 10 formed with the planar layer 17 .

[0109] S500 , forming a transmissive conductive layer 20 on the substrate 10 formed with the signal line 19 , the orthographic projection of the transmissive conductive layer 20 on the substrate 10 covers the orthographic projection of the photodiode 11 on the substrate 10 .

[0110] Or S500', synchronously forming a transmissive conductive layer 20 and a conductive pattern on the substrate 10 formed with the signal line 19, the orthographic projection of the transmissive conductive layer 20 on the substrate 10 covers the orthographic projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com