Processing method for anti-collision square tube, and product of processing method

A processing method and anti-collision technology, which is applied in the field of containers, can solve the problems of low per capita working hours efficiency, labor-intensive, cumbersome processes, etc., and achieve the effects of saving labor and energy costs, improving the efficiency of manual working hours, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0023] The present invention is a kind of processing method of anti-collision square tube, comprises the following steps:

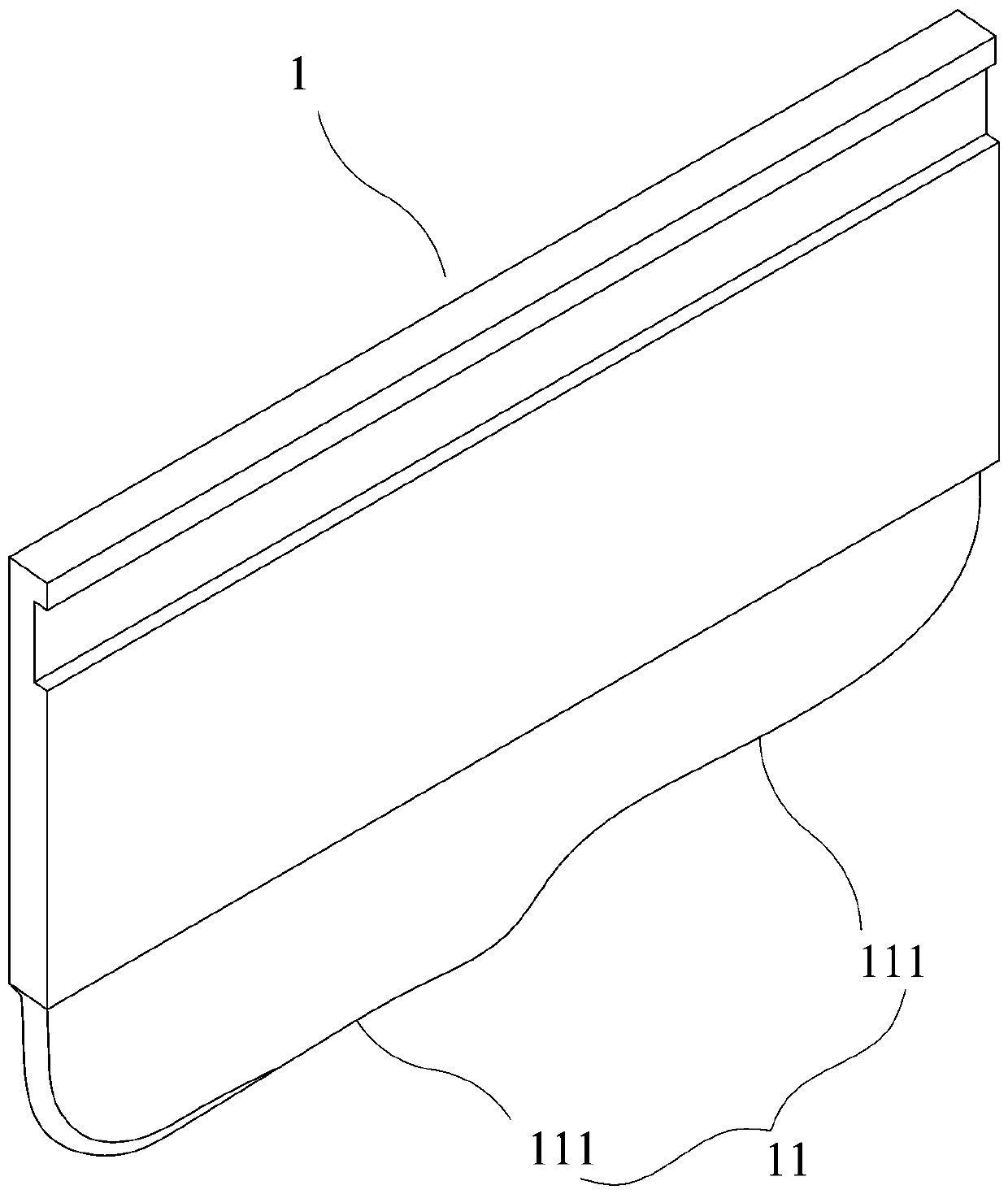

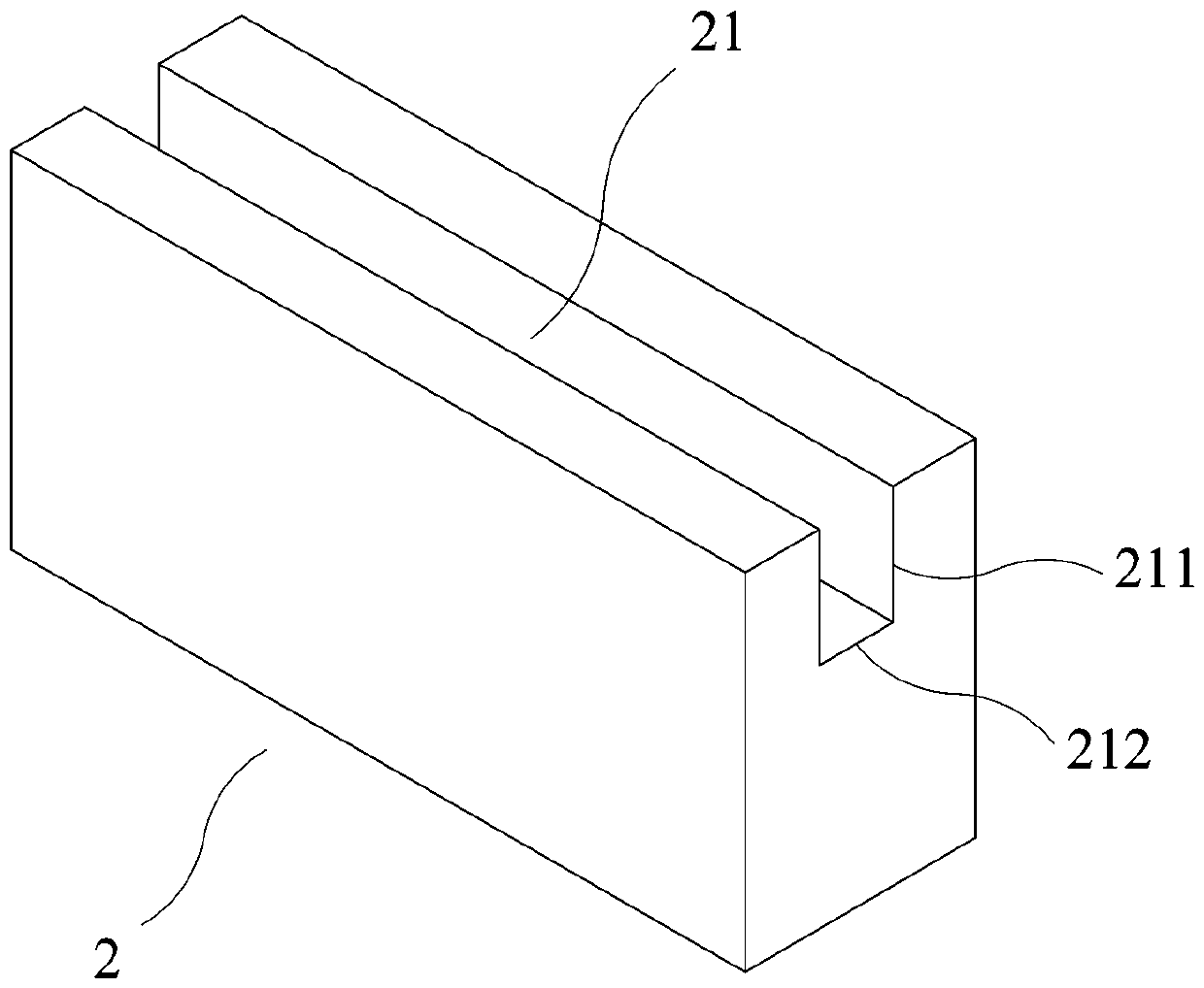

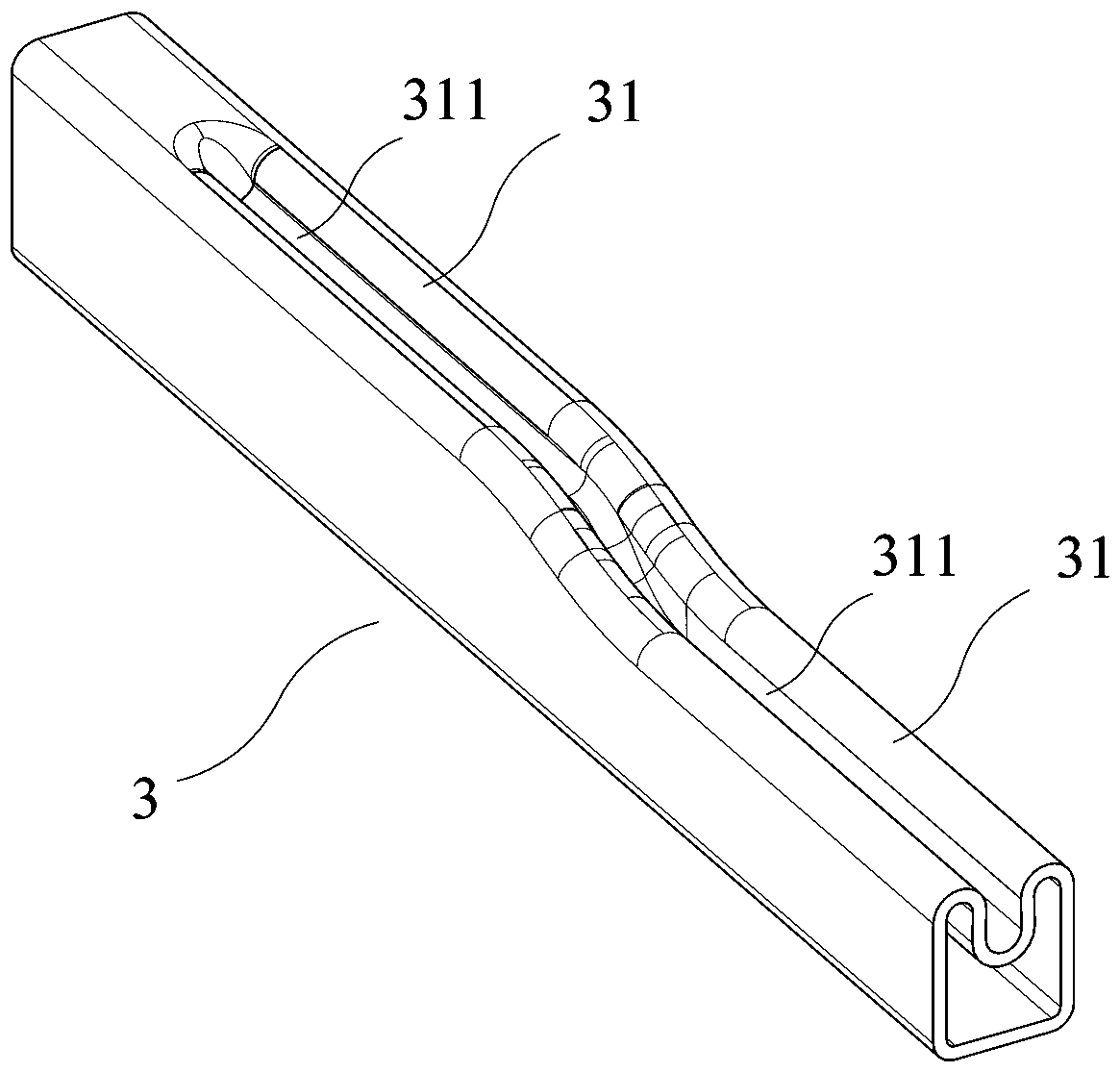

[0024] Step 1, design the corresponding upper mold 1 and lower mold 2 according to the size parameters of the anti-collision square tube 3; wherein refer to figure 1 and figure 2 Shown, above-mentioned upper mold 1 has profiling knife edge 11, and profiling knife edge 11 comprises the blade 111 identical with the number of the notch 31 that gives way to the anti-collision square pipe 3, the height difference of blade 111 and the abdication of anti-collision square pipe 3 The height difference of the notch 31 matches, and the above-mentioned lower mold 2 has a profiling placement groove 21, and the width of the profiling placement groove 21 matches the width of the anti-collision square t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com